Friction clutch for at least one running wheel of a track-bound traction vehicle

A technology of rotating wheels and clutches, which is applied to transmissions driven by electric motors, slip couplings, couplings, etc., and can solve problems such as inability to adjust sliding clutches, difficult access to repairs or maintenance, and complicated preparation methods. , achieve the effect of shortening maintenance time, simplifying disassembly work and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

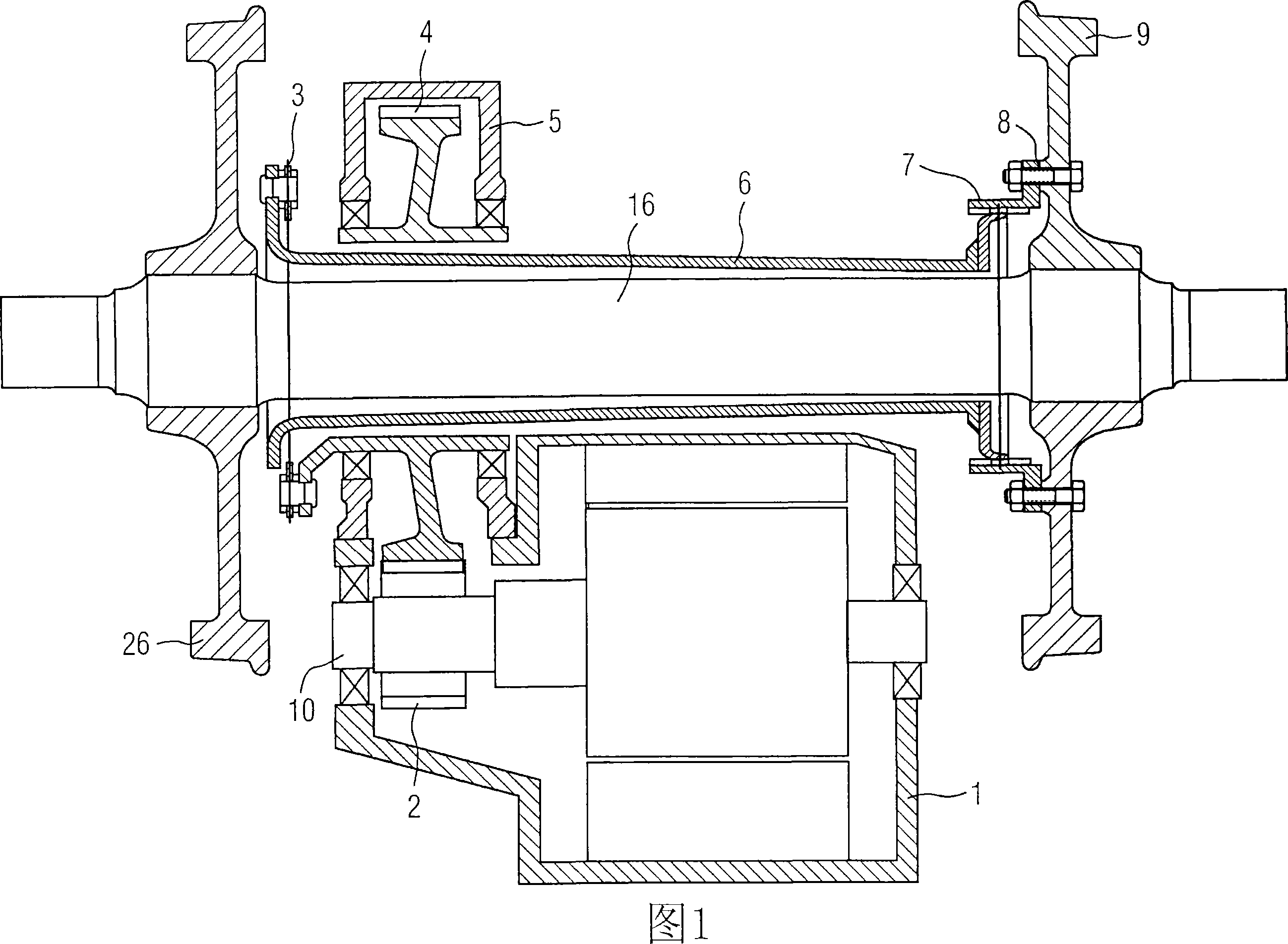

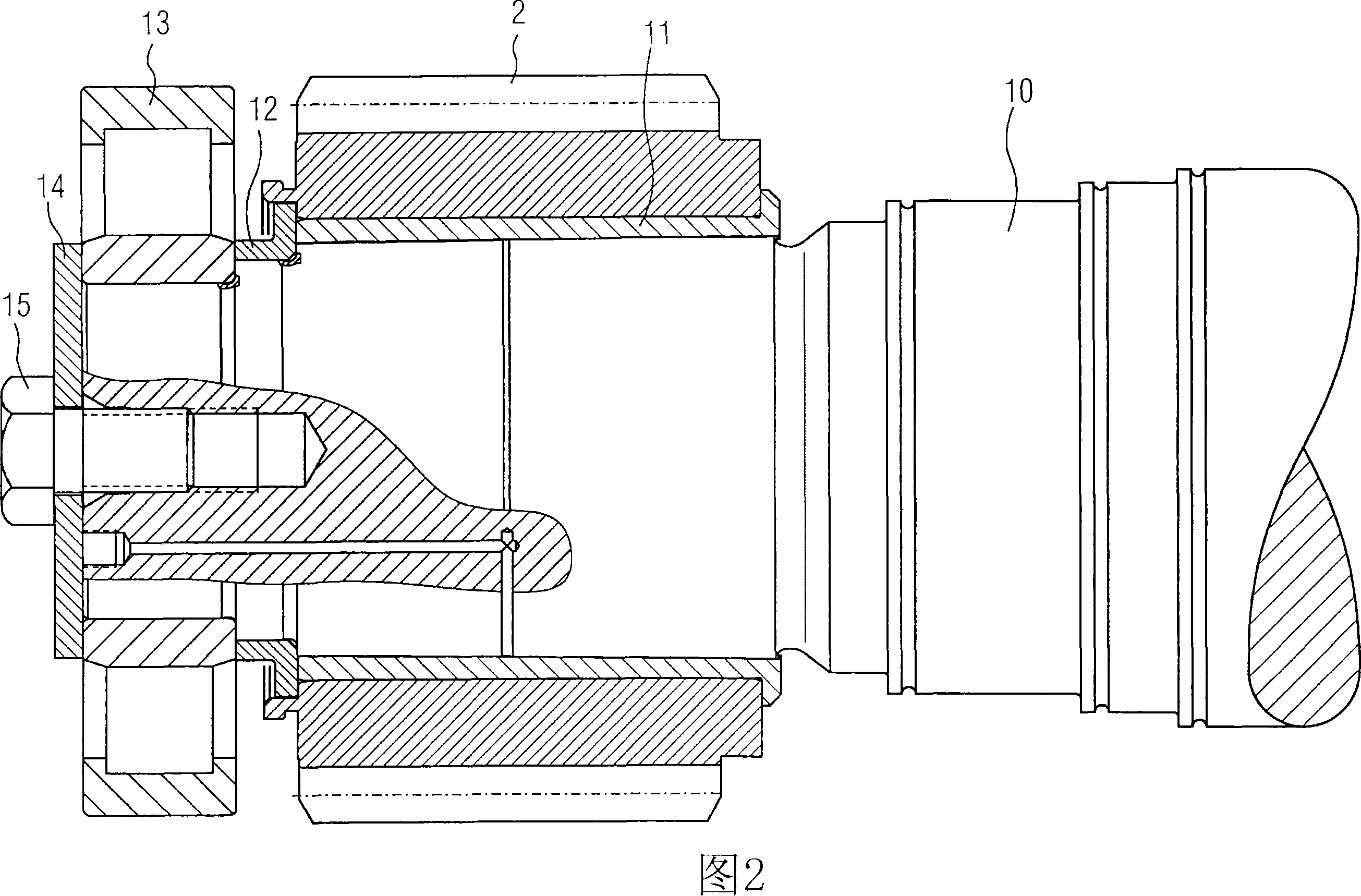

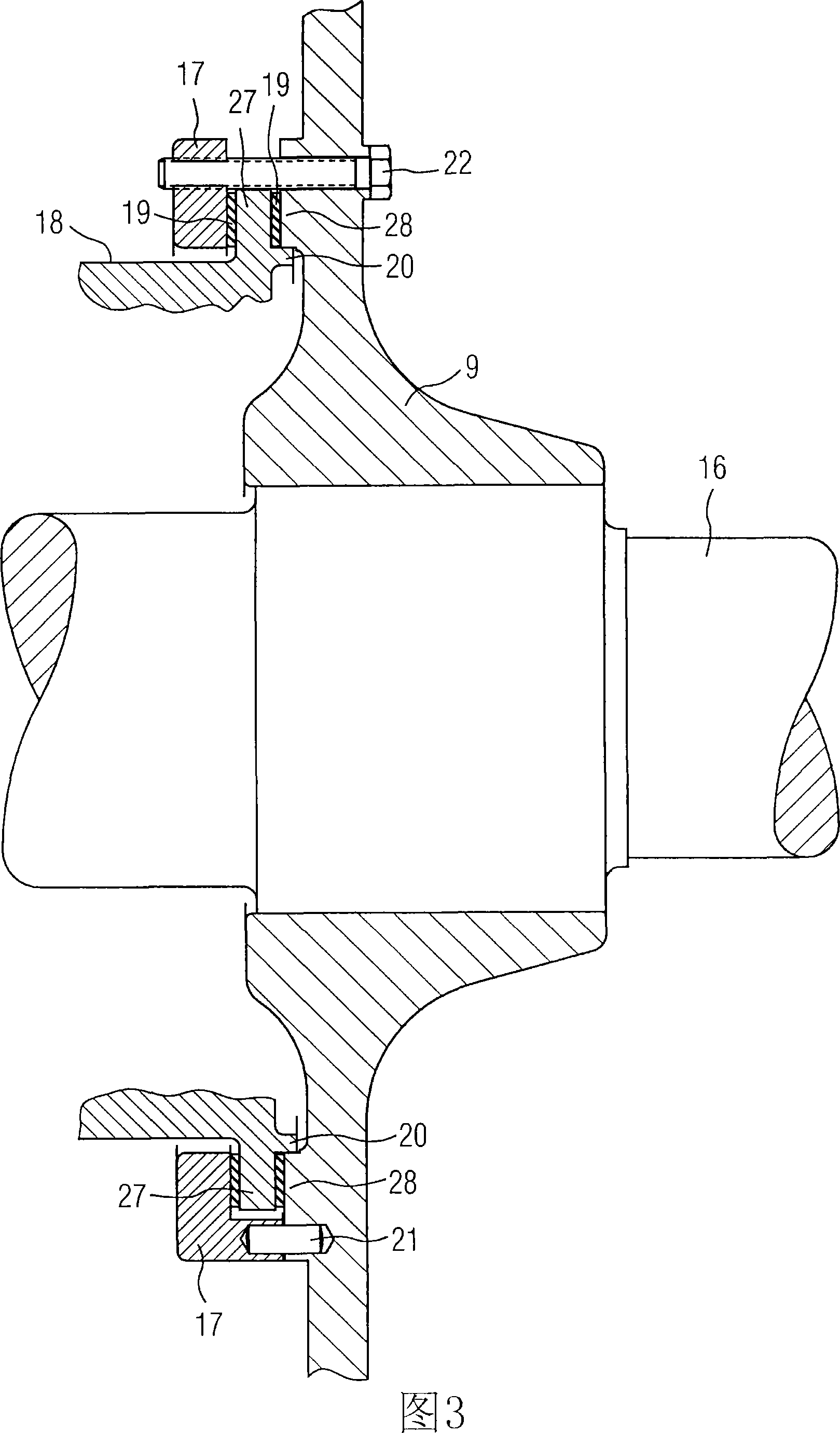

[0029] Figure 1 shows the drive train of a prior art railcar. A traction motor 1 drives an electric pinion 2 fixed on a motor shaft 10 . The electric pinion 2 is connected via its tooth flanks to a transmission bull gear 4 mounted in a single-stage transmission 5 . The drive gear wheel 4 is connected via a drive-side axial clutch joint 3 to an axial clutch hollow shaft 6 , which in turn is connected to a running wheel-side axial clutch joint 7 . The axial clutch coupling 7 on the runner side is connected to the runner 9 via a flange screw connection 8 . The rotating wheel 9 is connected on an axle 16, and another rotating wheel 26 is installed on the other end of the axle 16. Wherein, the function of the axial clutch hollow shaft 6 is also to realize the suspension, so as to avoid the undesired rigid coupling between the traction motor and the running wheel. Such drive trains in the prior art must be oversized in order to prevent failures caused by short-circuit surge torqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com