Rotating-head machine for packaging products in sealed film

A sealing film, rotating head technology, applied in packaging sealing/fastening, packaging, transport packaging, etc., can solve problems such as sealing burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

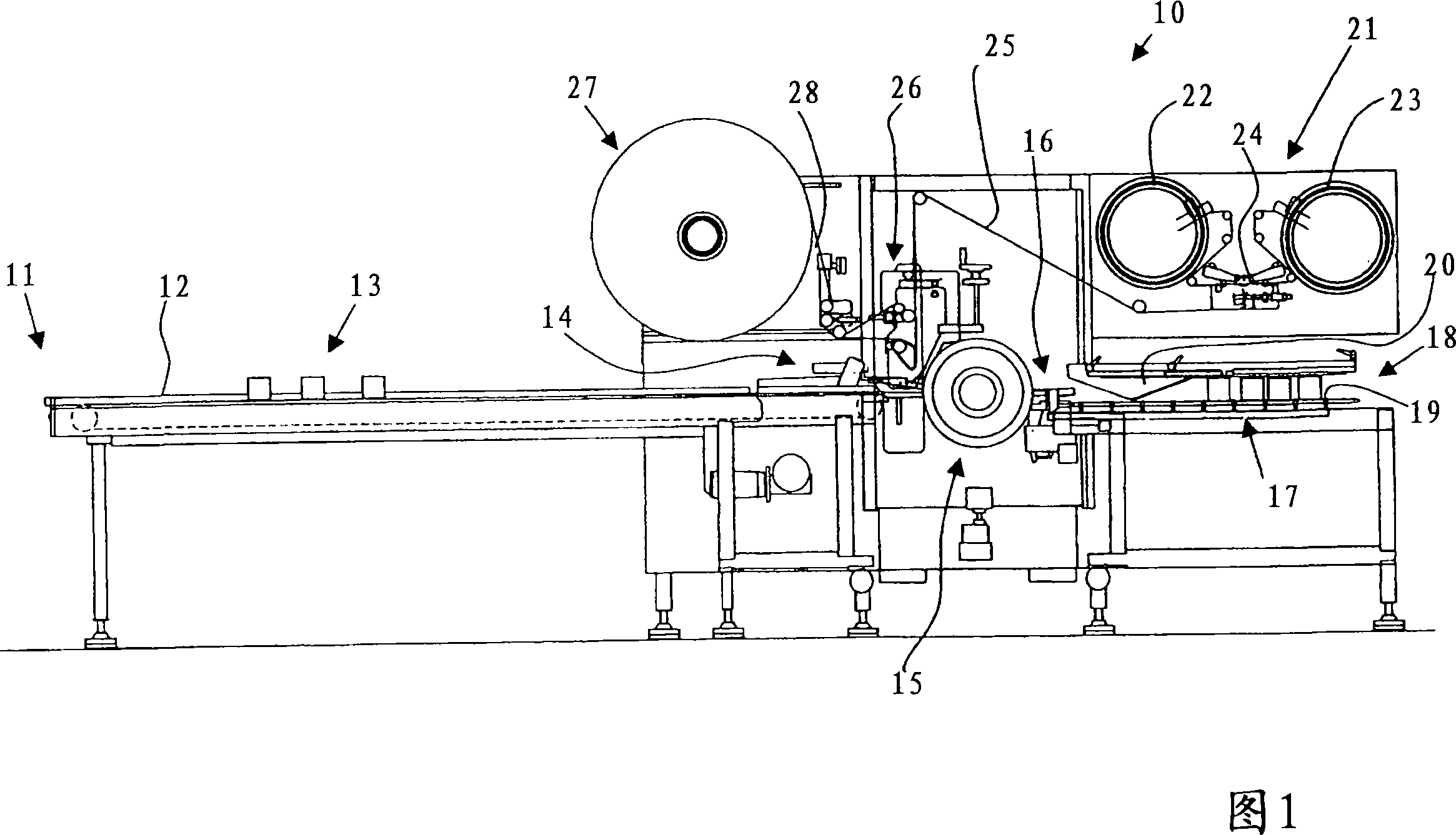

[0016] Referring to the drawings, Figure 1 shows a packaging machine, generally indicated at 10, made in accordance with the principles of the present invention. The machine 10 has an inlet 11 with a feed table 12 on which products 13 are loaded, manually or automatically, individually or in groups, in the quantities envisaged for packaging. The infeed station advantageously receives the products to be packaged sequentially and delivers them to the product loading station 14 in the packaging head 15 , advantageously in the form of a known slat conveyor system. The loading station may comprise a known pushing unit at the end of the infeed table to pick up the products and push them into the packing head.

[0017] The products at least partially packed by the head 15 are moved from the head to the opposite unloading station 16 for delivery along the outlet table 17 to the outlet 18 . As will become clear below, the outlet station 17 may advantageously comprise known devices or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com