Hypotensive agent produced by cultivation of lactic acid bacterium

A technology of lactic acid bacteria culture and antihypertensive agent, which is applied in the direction of bacteria, dairy products, cardiovascular system diseases, etc., and can solve the problems of high blood pressure without knowing whether it is effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] (Example 1) Preparation (1) of lactic acid bacteria culture using spirulina and measurement of the number of lactic acid bacteria

[0076]25kg of galacto-oligosaccharides and 825kg of tap water are loaded into a culture tank with a capacity of 2500L. After heat sterilization, 100kg of spirulina bulk material is added, and 50kg of seed culture solution of lactic acid bacteria Lactobacillus brevis is inoculated. Lactic acid bacteria were cultured at 37°C for 72 hours under agitation with an aerated propeller. The culture solution with the culture time of 0, 9, 12, 15, 18, 24, 48 and 72 hours was sampled to measure the number of lactic acid bacteria.

[0077] In addition, the measurement of the number of lactic acid bacteria was performed in the following procedure. Suspend 1.0 ml of lactic acid bacteria culture solution in 19 ml of phosphate-buffered saline to prepare a suspension. The suspension was further diluted 10-fold, 10-fold with phosphate-buffered saline 2 tim...

Embodiment 2

[0088] (Example 2) Preparation of lactic acid bacteria culture using spirulina (2)

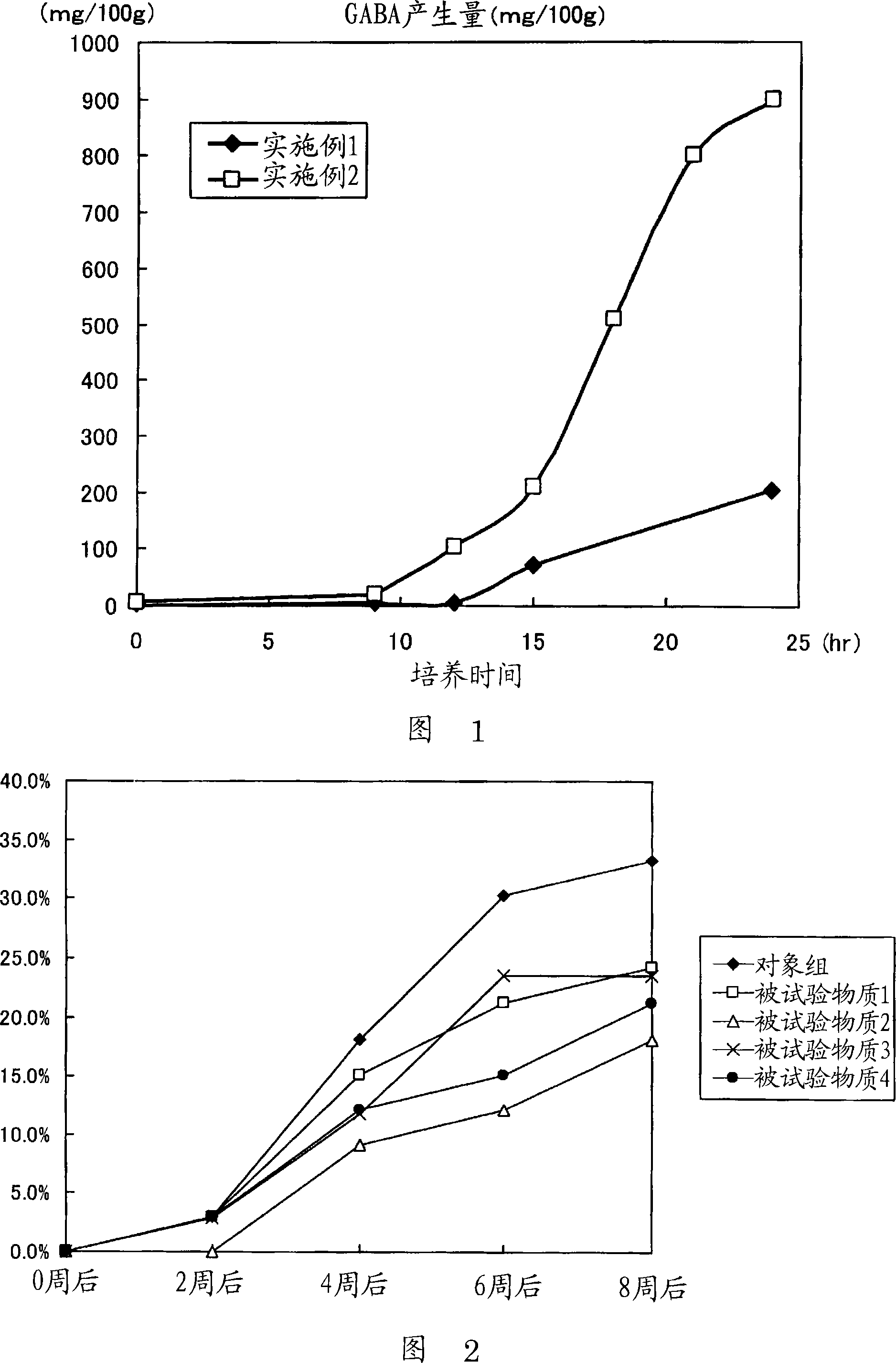

[0089] In this example, lactic acid bacteria were cultivated in the same manner as in Example 1, except that the pH was maintained at 5.0 with a 50% (w / w) lactic acid solution and the culture temperature was maintained at 30°C. The culture solution with the culture time of 0, 9, 12, 15, 18, 21 and 24 hours was sampled, and the amount of GABA (mg / 100g) was measured.

Embodiment 3

[0090] (Example 3) Preparation of lactic acid bacteria culture using spirulina (3)

[0091] In this example, except that xylooligosaccharide was used instead of galactooligosaccharide, the same operation was performed as in Example 2, and the amount of GABA (mg / 100g) was measured.

[0092] The comparison of the GABA amount (mg / 100g) of Example 1 and Example 2 up to the culture time of 24 hours is shown in FIG. 1, and the result of Example 2 and Example 3 is shown in Table 2.

[0093] Through Examples 1-3, the appropriate pH and culture temperature are selected, so that more GABA can be produced in a short time.

[0094] Table 2

[0095] GABA content (mg / 100g)

[0096] Training time

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com