Internal water cooling motor

An electric motor and water cooling technology, applied in the field of electric motors, can solve problems such as the inability to meet the cooling requirements of electric motors, and achieve the effects of reducing abnormal wear, good effect and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

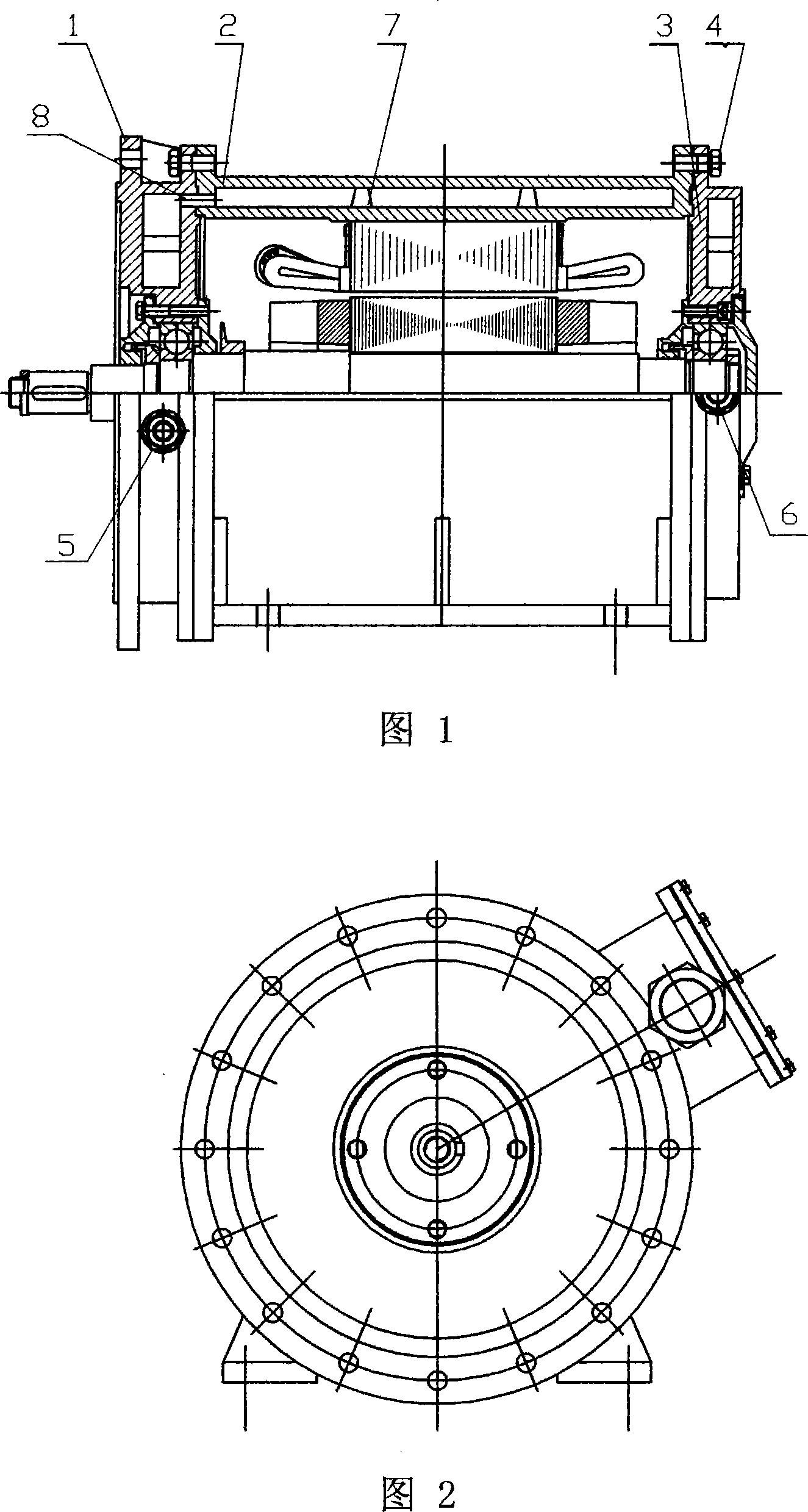

[0015] Embodiment 1 is a 30KW marine motor used in an electric reciprocating pump in the engine room of a 300,000-ton freighter, and the rated power of the internal water-cooled motor is small. The water inlet 5 of the left end cover 1 and the water outlet 6 of the right end cover 3 are connected by M25mm internal threaded holes, and the cooling water pipe with an inner diameter of φ20mm meets the supply of cooling water. When the ship sails normally, the temperature in the engine room reaches 60°C to 80°C, and the temperature of the motor shell of the prior art working under this environment is 110°C to 130°C. A motor with a water-cooled structure is used as a comparative test. Under the same conditions, the flow introduced from the water inlet 5 of the left end cover 1 is 0.01m 3 / s, the cooling water with a water temperature of 15°C flows out from the water outlet 5 of the right end cover 3 after heat exchange, and the motor can be cooled and kept at 65°C to 85°C within 13 ...

Embodiment 2

[0016] Embodiment 2 is to use the built-in water-cooled structure motor in the same freighter engine room, its rated power is 82KW, the calorific value is larger than that of Embodiment 1, and the amount of cooling water consumed is also more than Embodiment 1. In this embodiment, the water inlet 5 of the left end cover 1 and the water outlet 6 of the right end cover 3 adopt a flange connection structure, and the inner hole is 25 mm. The shell 2 is provided with 18 axially staggered elongated ribs 7 to form an axial labyrinth water channel, and the flow rate introduced from the water inlet 5 of the left end cover 1 is 0.03m 3 / s, cooling water with a water temperature of 15°C flows out from the water outlet of the right end cover 3 after heat exchange, and the cooling water can be cooled to 70°C to 90°C within 10 minutes to ensure that the motor operates at a safe temperature.

Embodiment 3

[0017] Embodiment 3 is the same as Embodiment 2, except that the water channel provided in the casing 2 is formed by spiral ribs 7 to form a spiral water channel. The heat exchange time of the cooling water in the internal water channel of this structure is long, and the cooling effect is better than that of Examples 1 and 2.

[0018] The cooling water temperature introduced in the present invention directly affects the cooling effect. The cooling effect of cooling water at a low temperature is better than that of cooling water at a slightly higher temperature.

[0019] The invention is an internal water-cooled motor, which adopts a fully enclosed structure, so that dust in the environment cannot enter the inside of the motor, keeps the inside of the motor clean, effectively reduces abnormal wear and tear, and improves the service life of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com