Apparatus and method for processing elevator wire rope groove

A groove processing and steel cable technology, which is applied in the direction of metal processing equipment, elevators in buildings, grinding/polishing safety devices, etc., can solve the problems of not considering the refurbishment processing, deflector wheel refurbishment processing, etc., Achieve the effects of suppressing tool replacement frequency, preventing deterioration of machining accuracy, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

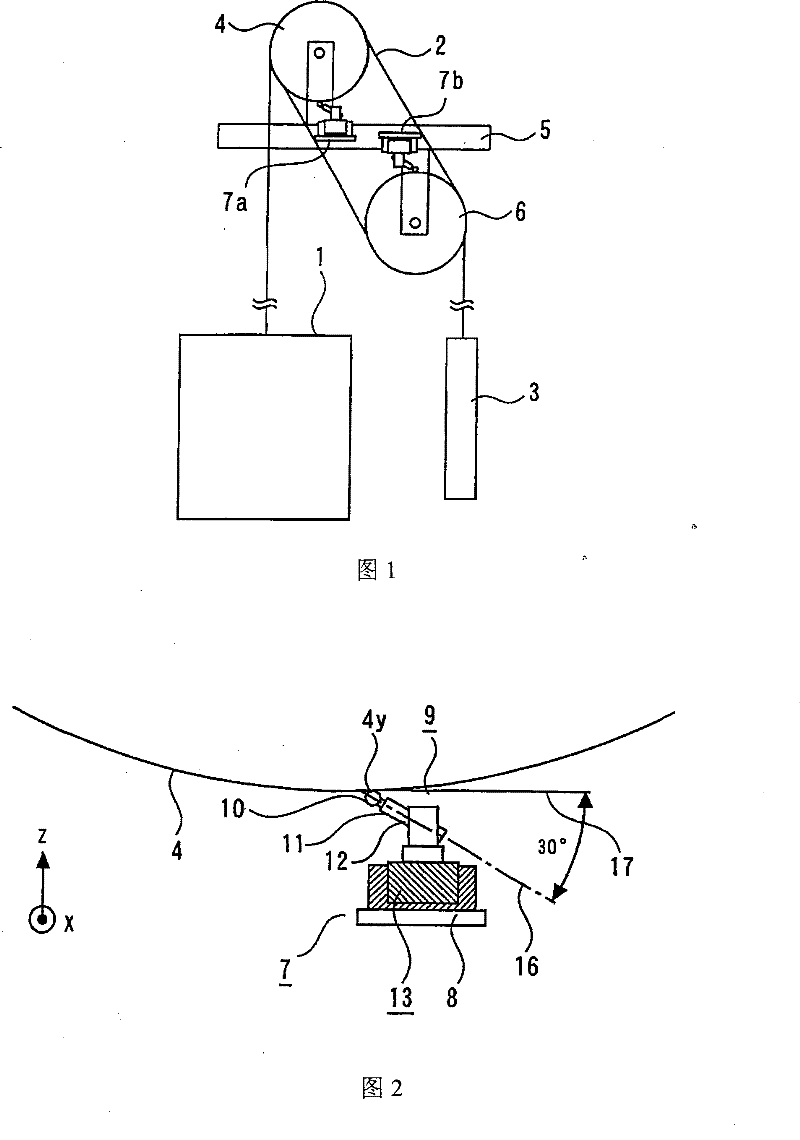

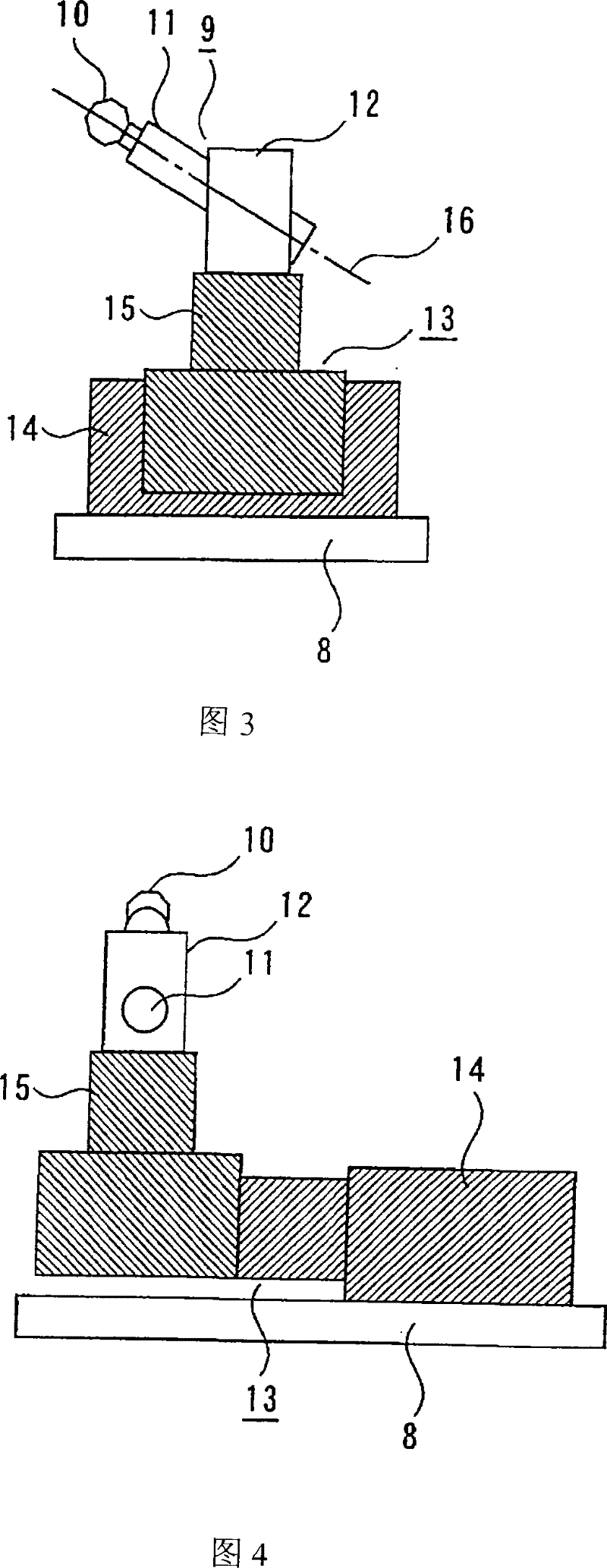

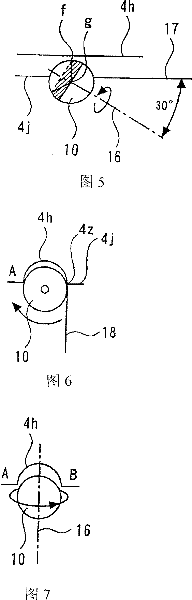

[0073] figure 1 It is a schematic configuration diagram of an elevator apparatus in a state where the elevator cable groove processing apparatus according to Embodiment 1 of the present invention is installed; figure 2 It is a side view showing the installation of the elevator cable groove processing device in Embodiment 1 of the present invention; image 3 It is a side view for explaining the movable state of the movable support part of the cable groove processing device in Embodiment 1 of the present invention; Figure 4 It is a rear view for explaining the movable state of the movable support part of the cable groove processing device in Embodiment 1 of the present invention; Figure 5 It is a side view when the angle between the rotation axis of the processing part and the tangent line at the processing point on the driving cable pulley is 30 degrees; Figure 6 It is the front view when the angle between the rotation axis of the processing part and the tangent line at ...

Embodiment approach 2

[0094] Figure 8 It is a side view of the elevator cable groove processing device in Embodiment 2 of the present invention, Figure 9 It is a front view of the cable groove processing device in Embodiment 2 of the present invention, Figure 10 It is a rear view of the cable groove processing device in Embodiment 2 of the present invention, Figure 11 It is a flowchart showing the steps of controlling the feed amount according to the position measurement value of the elevator cable groove processing device in Embodiment 2 of the present invention, Figure 12 is a flow chart showing the steps of controlling the feed rate according to the measured temperature value, Figure 13 It is a flow chart showing the procedure for controlling the feed rate according to the load measurement value. In the figure, the same or equivalent parts as those in Embodiment 1 are given the same reference numerals, and description thereof will be omitted.

[0095] In Embodiment 2, the processing ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com