A mesoporous Pt/WO* electro-catalyst and its preparing method

An electrocatalyst and mesoporous technology, applied in the field of electrocatalytic materials, to achieve the effects of uniform grain size, mild preparation conditions, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

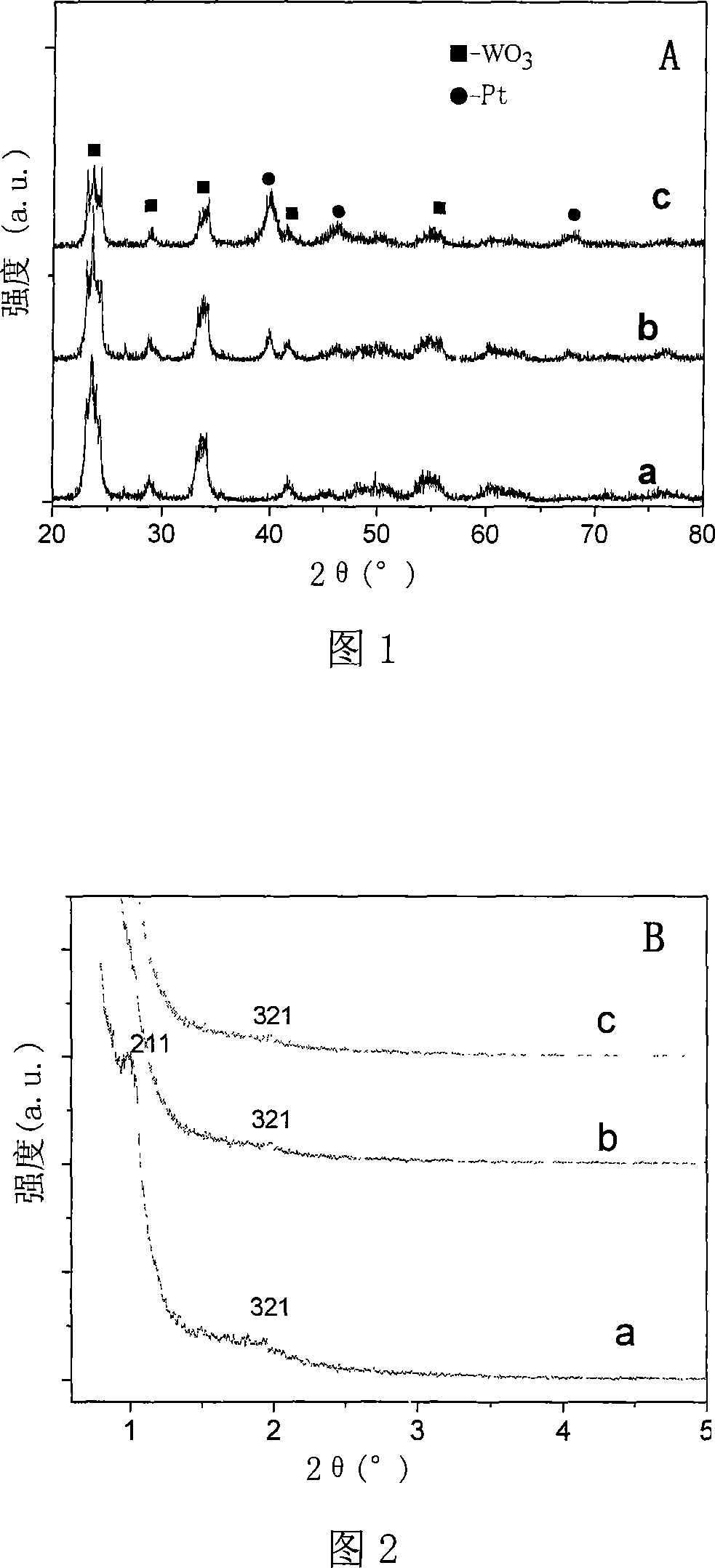

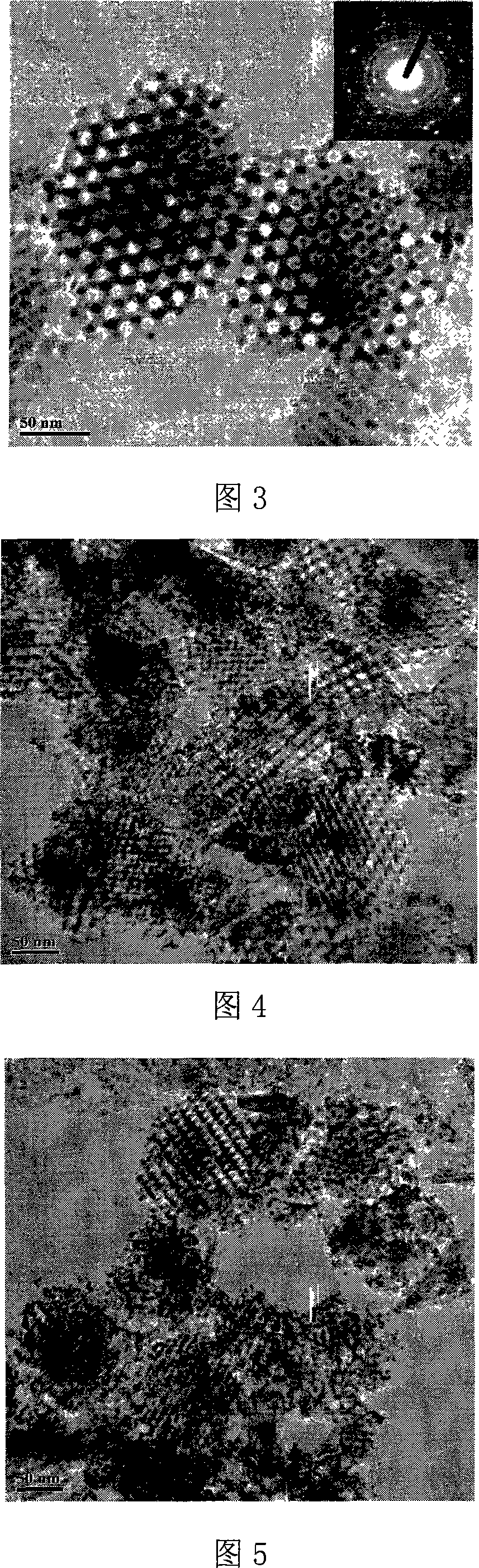

[0026] According to the literature report, the template material mesoporous silica KIT-6 was prepared, and the mesoporous WO was prepared by the hard template replication method. 3 For the carrier material, the wide-angle XRD is shown in Figure 1a, and the small-angle XRD is shown in Figure 2a, and the transmission electron microscope photo is shown in Figure 3. Take 0.5g mesoporous WO 3 After the carrier material was ultrasonicated for 15 minutes in a mixture of 10ml of isopropanol and deionized water (volume ratio 1:1), 16.67ml of chloroplatinic acid solution with a concentration of 11.78g / l was added and diluted to 60ml, and continued ultrasonication for 30min to disperse After uniformity, under magnetic stirring at room temperature, slowly dropwise add 0.5 mol / l sodium borohydride solution that is 10 times more than the chloroplatinic acid solution, and continue stirring for 12 hours. The resulting suspension is centrifuged, washed with deionized water, and vacuum-dried at...

Embodiment 2

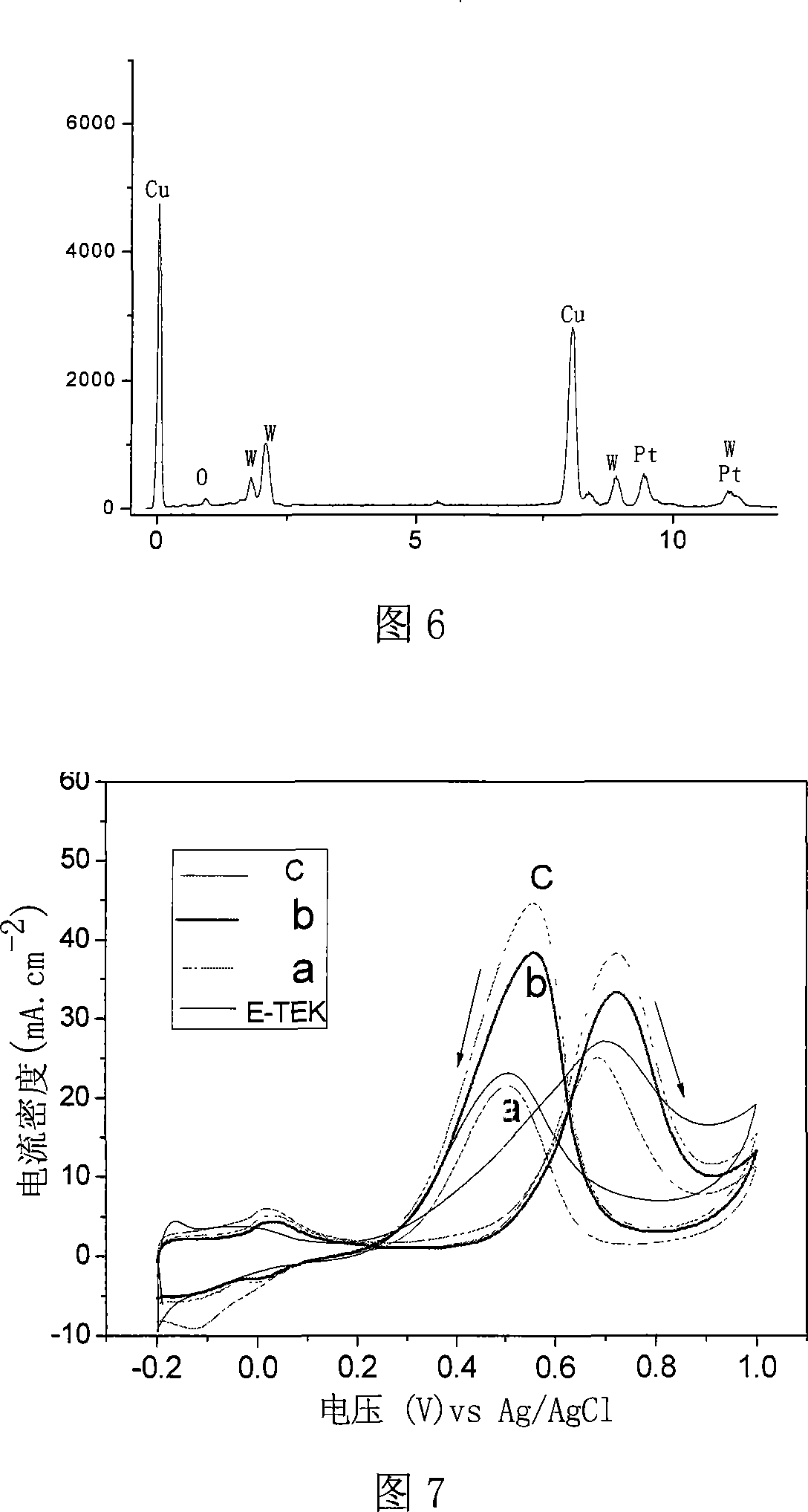

[0028] The types of experimental raw materials used and the operation are the same as in Example 1, changing H 2 PtCl 6 The amount of solution added to prepare 15wt% Pt / WO 3-mes Electrocatalyst, the wide-angle XRD of the catalyst is shown in Figure 1b, the small-angle XRD is shown in Figure 2b, the transmission electron microscope photo is shown in Figure 5, the EDS energy spectrum is shown in Figure 6, and the specific surface area is 72m 2 g -1 , the electrochemical oxidation catalysis of methanol is shown in Figure 7b.

Embodiment 3

[0030] The types of experimental raw materials used and the operation are the same as in Example 1, changing H 2 PtCl 6 The amount of solution added to prepare 10wt% Pt / WO 3-mes Electrocatalyst with a specific surface area of 78m 2 g -1 , the electrochemical oxidation catalysis of methanol is shown in c in Fig. 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com