Method for cleaning etching equipment component

A technology for etching equipment and components, applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., can solve problems affecting equipment, equipment service life reduction, component damage, etc. The effect of improving utilization and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

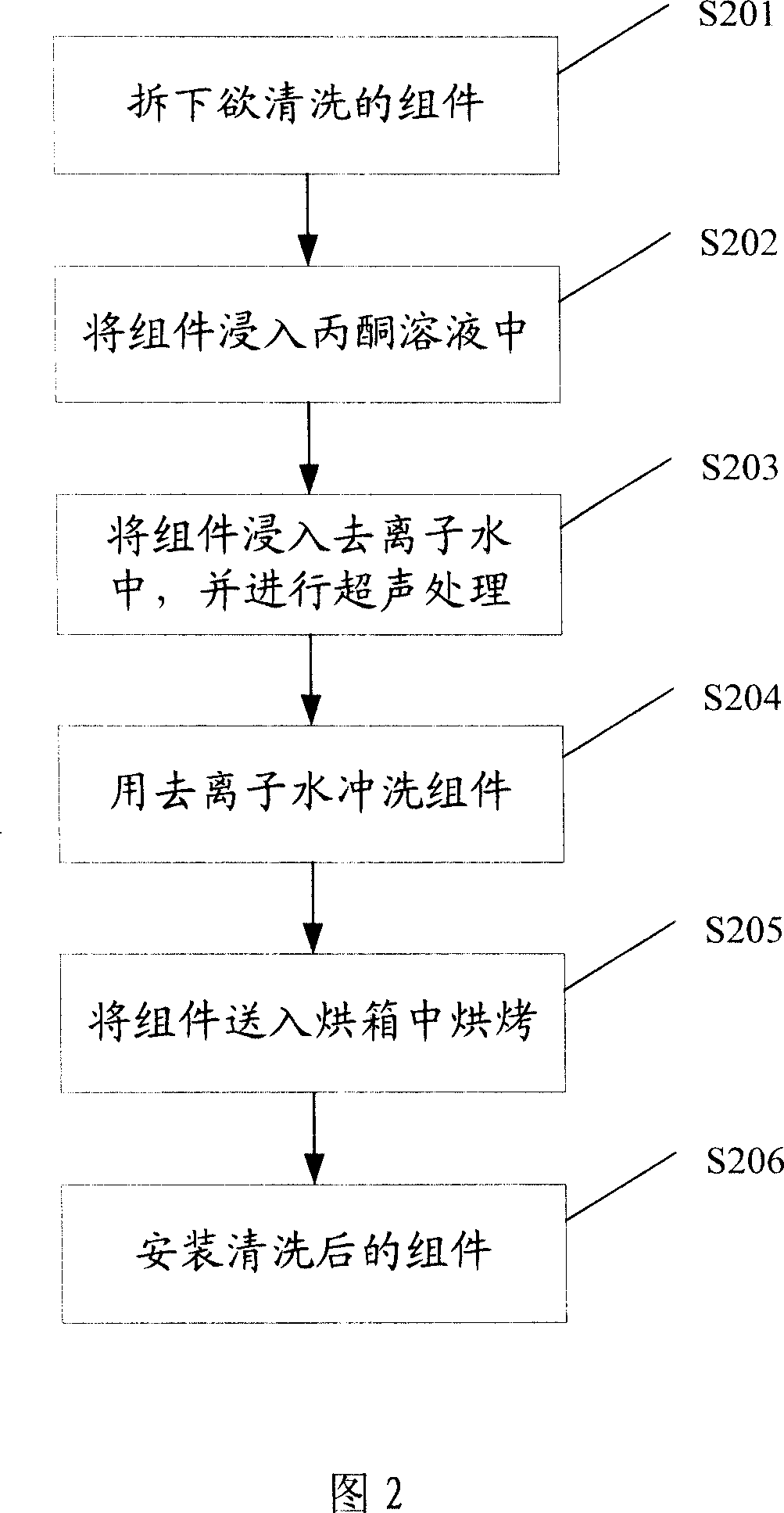

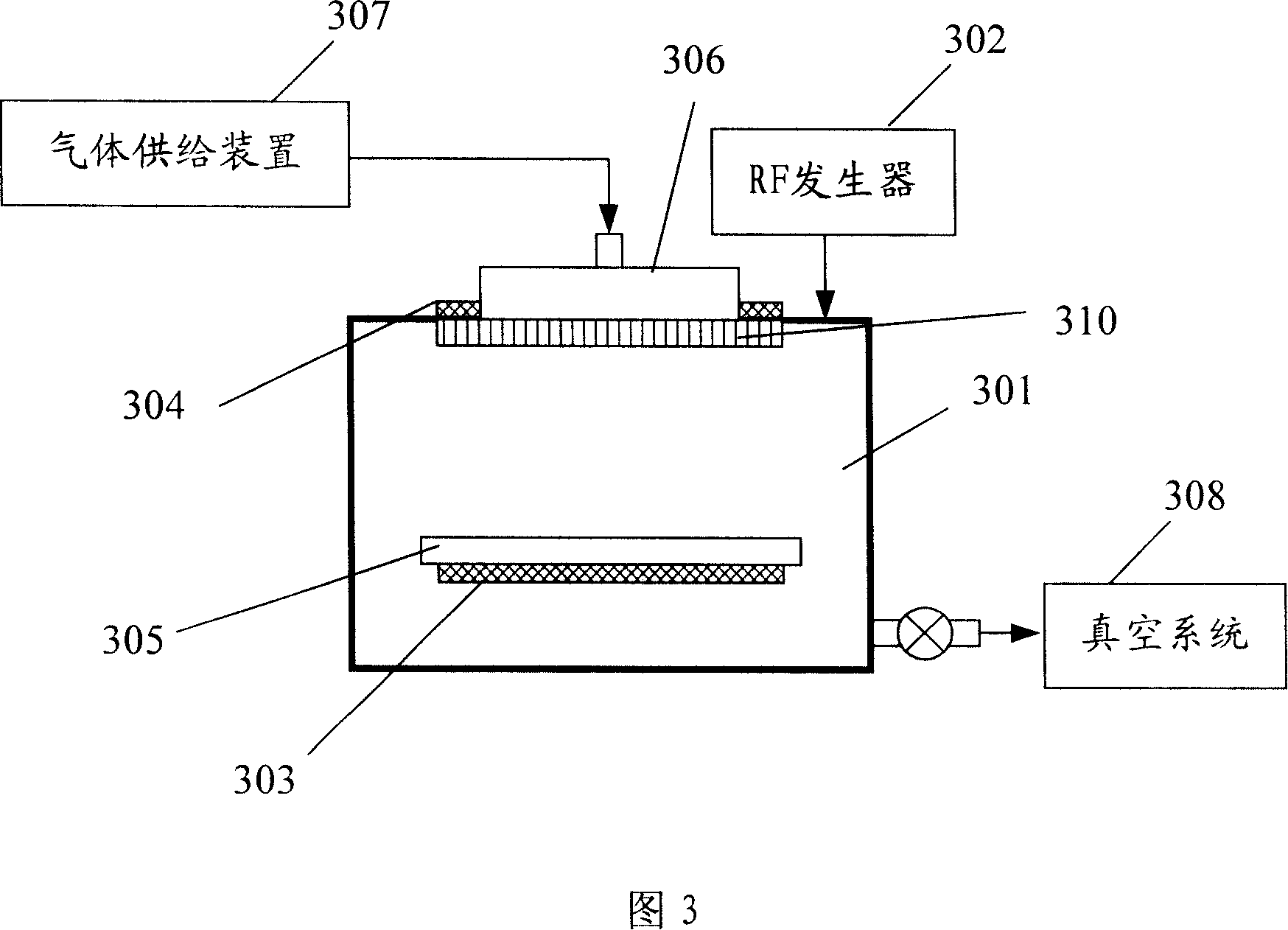

[0022] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] The processing method of the present invention can be widely applied in many applications, and should not be interpreted as only applicable to the cleaning of etching equipment components, for the cleaning of other equipment components to remove attachments, the method of the present invention is also applicable . The following is a specific description of the processing method of the present invention through a preferred embodiment, certainly the present invention is not limited to this specific embodiment, and the general replacements well known to those of ordinary skill in the art are undoubtedly included in the protection of the present invention within range.

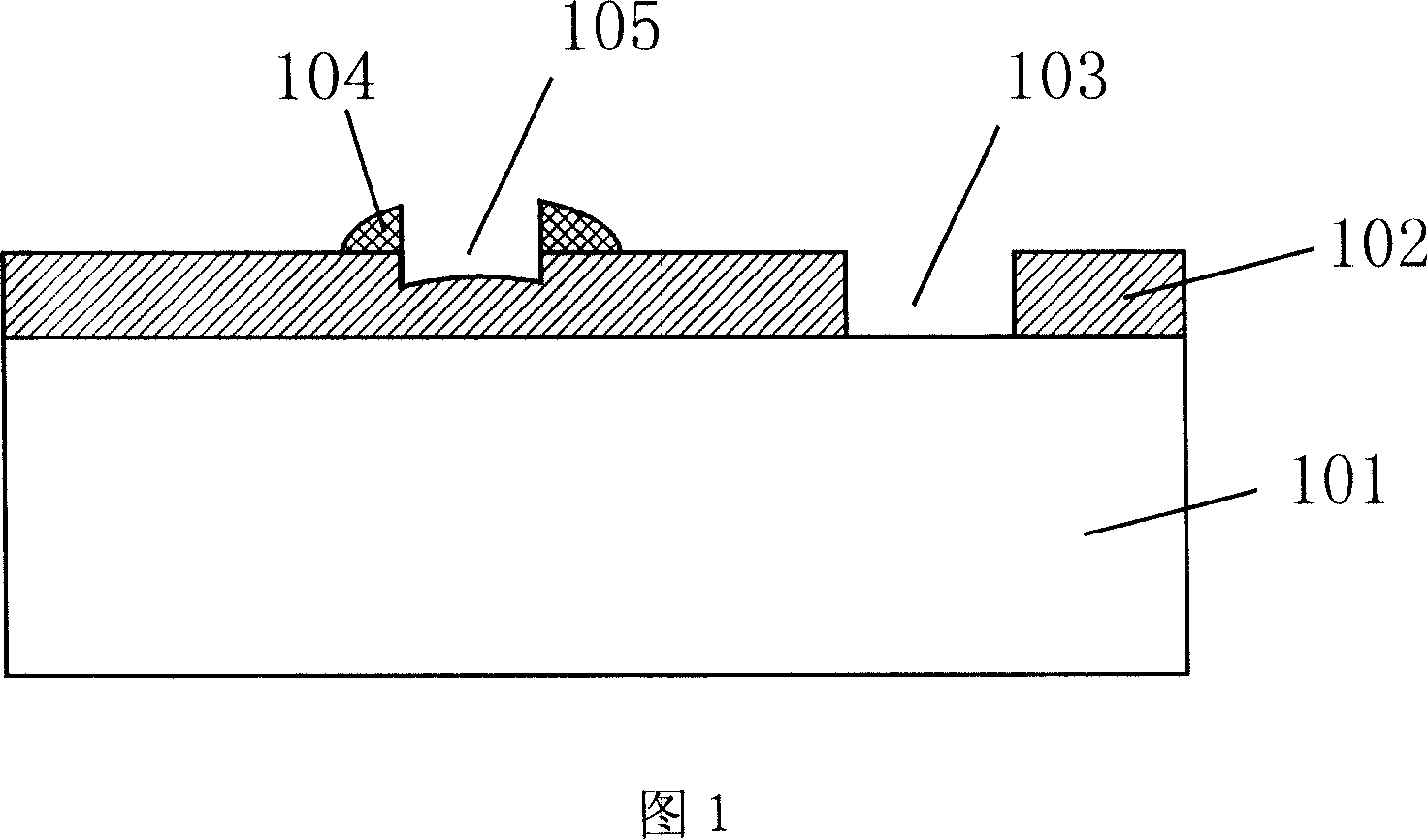

[0024] In order to clean the components in the etching equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com