Force induced switch and its application

A technology of inductive switch and contact switch, which is applied in the field of switch control devices, can solve the problems of unreliable contact of electrode sheets, easy aging of elastic insulating layer, and low reliability of use, and achieve reliable and accurate positioning and shooting, compact switch structure, Precisely tested and controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

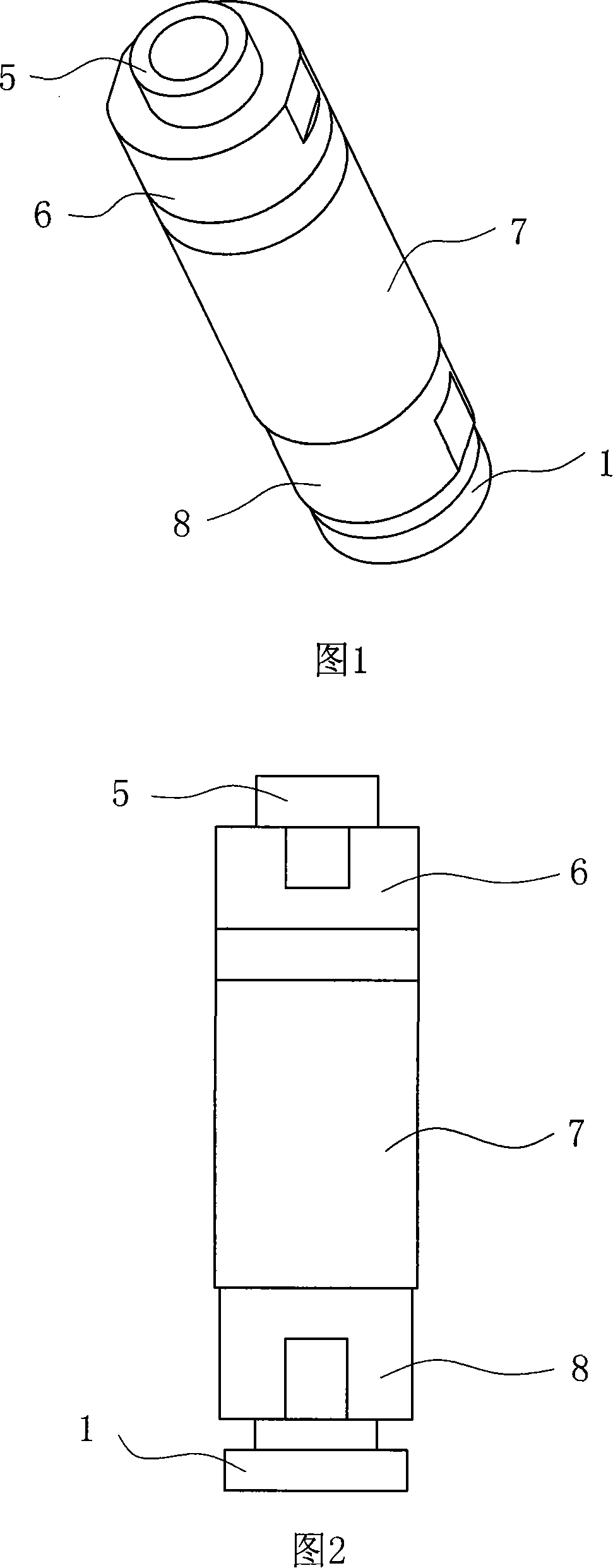

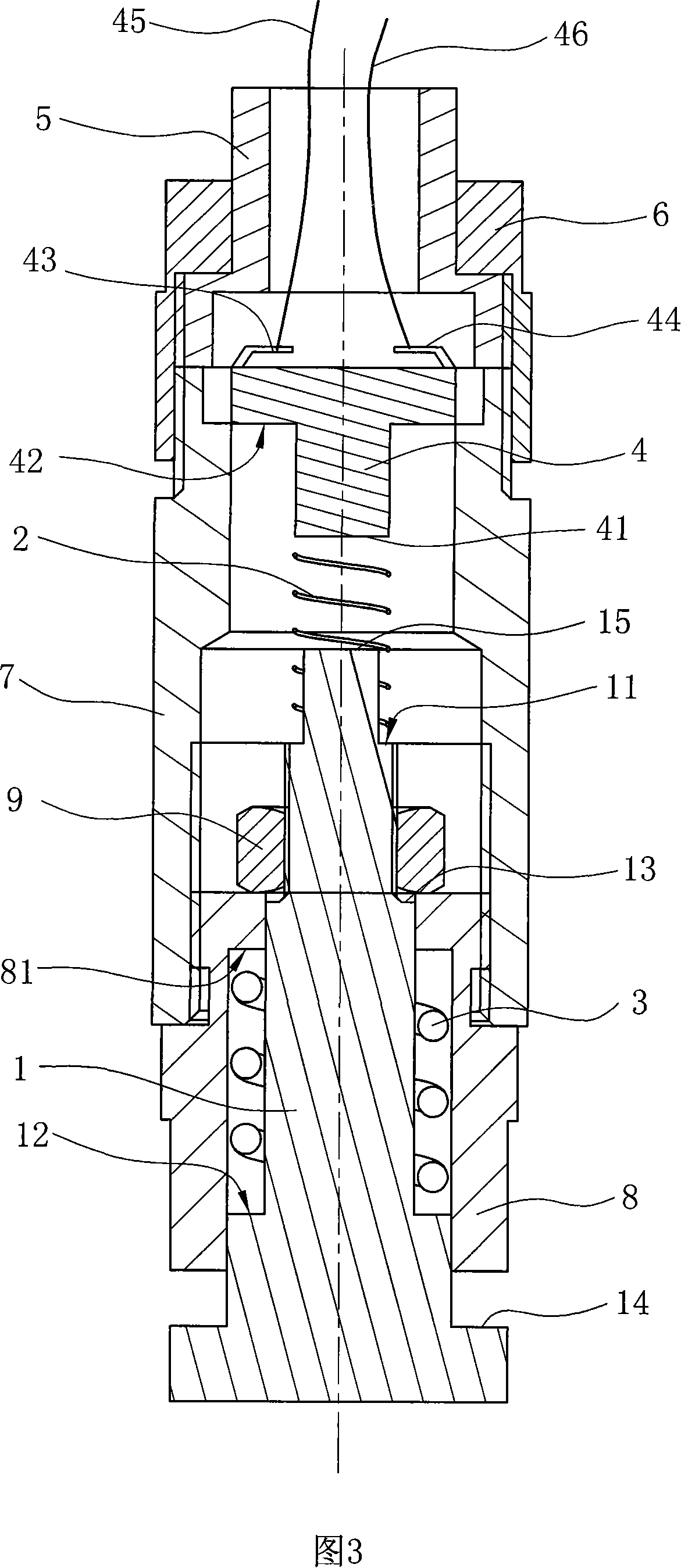

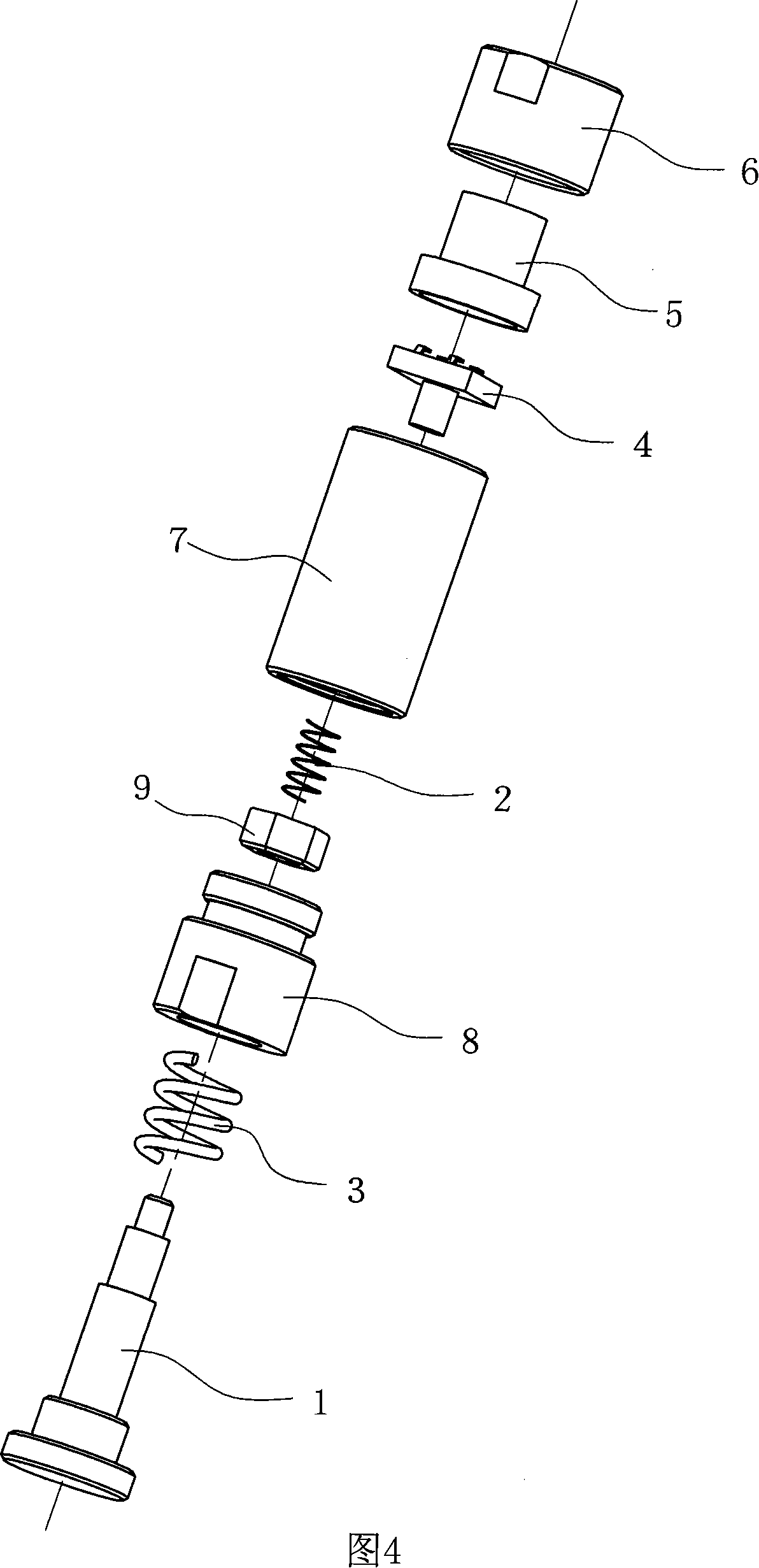

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] 1 to 8 are a preferred embodiment of the force sensing switch of the present invention, which includes a force transmission device composed of a first spring 2, a second spring 3 and a stepped shaft 1 with a second switch contact 15, Used to transmit external force; a contact switch 4 with a first switch contact 41 capable of inductively changing external force and lugs 43, 44; To fix and package the force transmission device and the contact switch 4.

[0034] Wherein, the stepped shaft 1 is installed in the bushing 8 and the shaft barrel 7, and can slide along the axial direction of the bushing 8 and the shaft barrel 7. The stepped shaft 1 has a first stepped surface 11 and a second stepped surface 12. , the third stepped surface 13 and the fourth stepped surface 14, the fourth stepped surface 14 is used as the bottom of the stepped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com