Water heater

A water heater and water inlet technology, which is applied in fluid heaters, lighting and heating equipment, etc., can solve the inconvenience of production and after-sales maintenance, the display cover of the anti-electric wall and the incorrect connection of the inlet and outlet water insulation pipes, and the inability to remove the magnesium rod And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

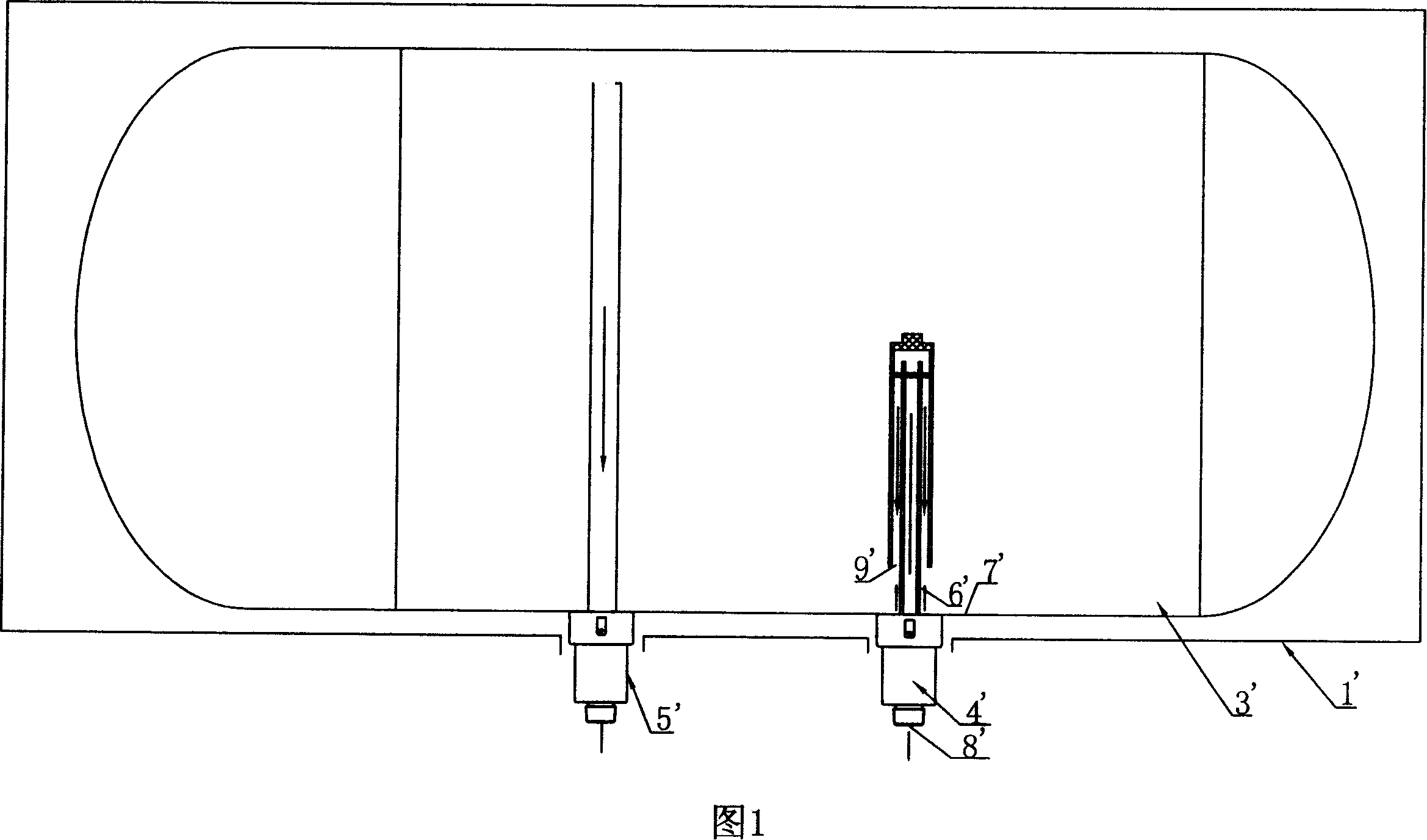

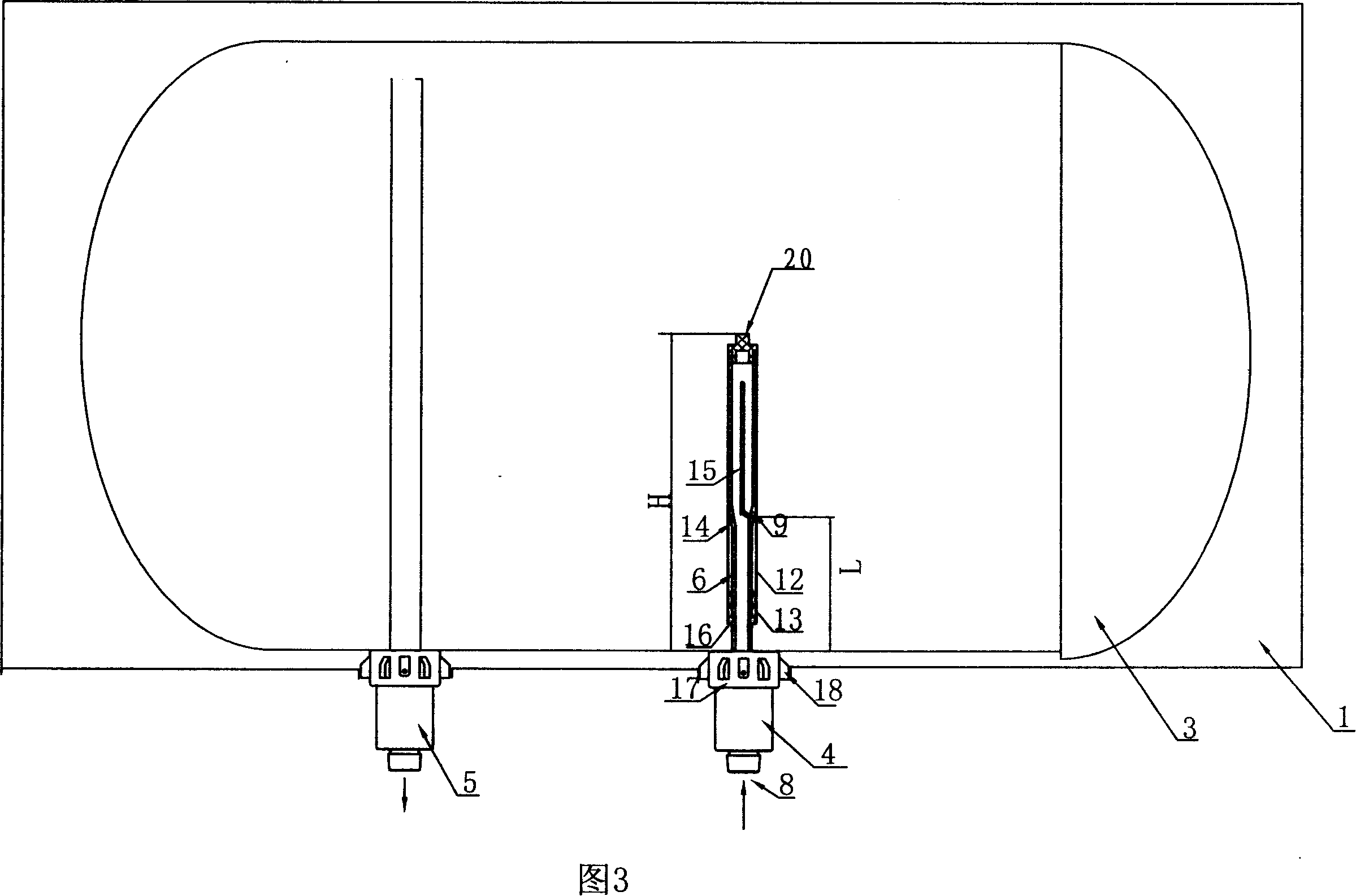

[0031] As shown in Figure 3 and Figure 6, the water heater according to the present invention includes a shell 1, a foam layer 2, an inner tank 3, a water inlet insulating pipe and a water outlet insulating pipe 5, and the outer shell is provided with a water inlet 11 and a water outlet 10. The water inlet insulating pipe includes the water inlet pipe 4 arranged outside the inner tank of the water heater, the inner pipe 6 arranged in the inner tank 3 and connected with the water inlet pipe 4, and the water inlet pipe 4 and the inner pipe 6 are connected through a screw head 17, Its main feature is that at least two positioning ribs 18 that can fix the liner 3 without shifting are provided on the screw heads of the water inlet pipe and the water outlet pipe corresponding to the water inlet hole 11 and the water outlet hole 10 of the water heater shell. There are 6 places.

[0032] As shown in Fig. 3 to Fig. 5, the water inlet insulating pipe described in the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com