Transverse connecting rod for vehicle

A technology of transverse link and vehicle, which is applied in the direction of vehicle components, cantilever mounted on the pivot, suspension, etc., which can solve the problem of demanding space and achieve the effect of improving force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

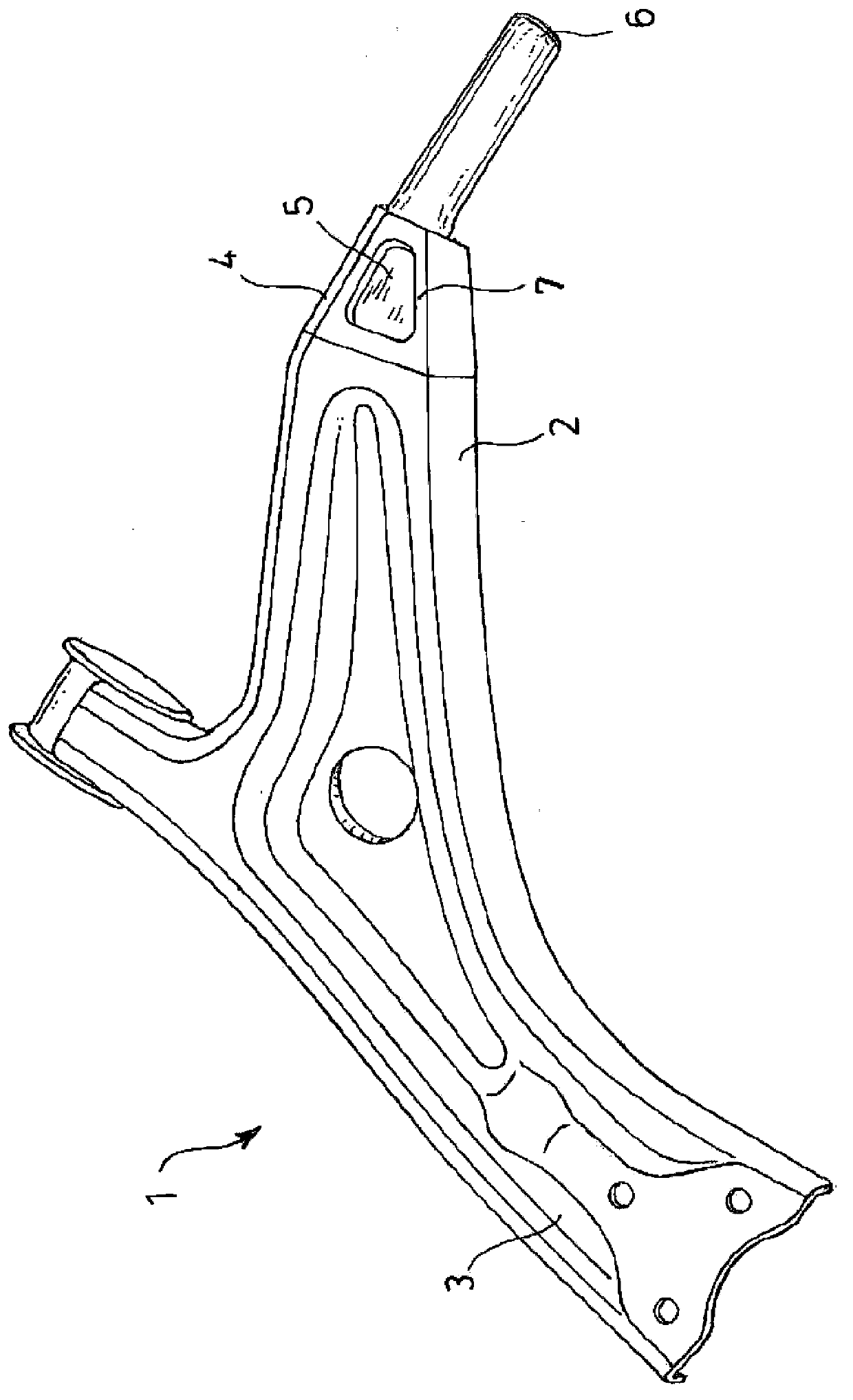

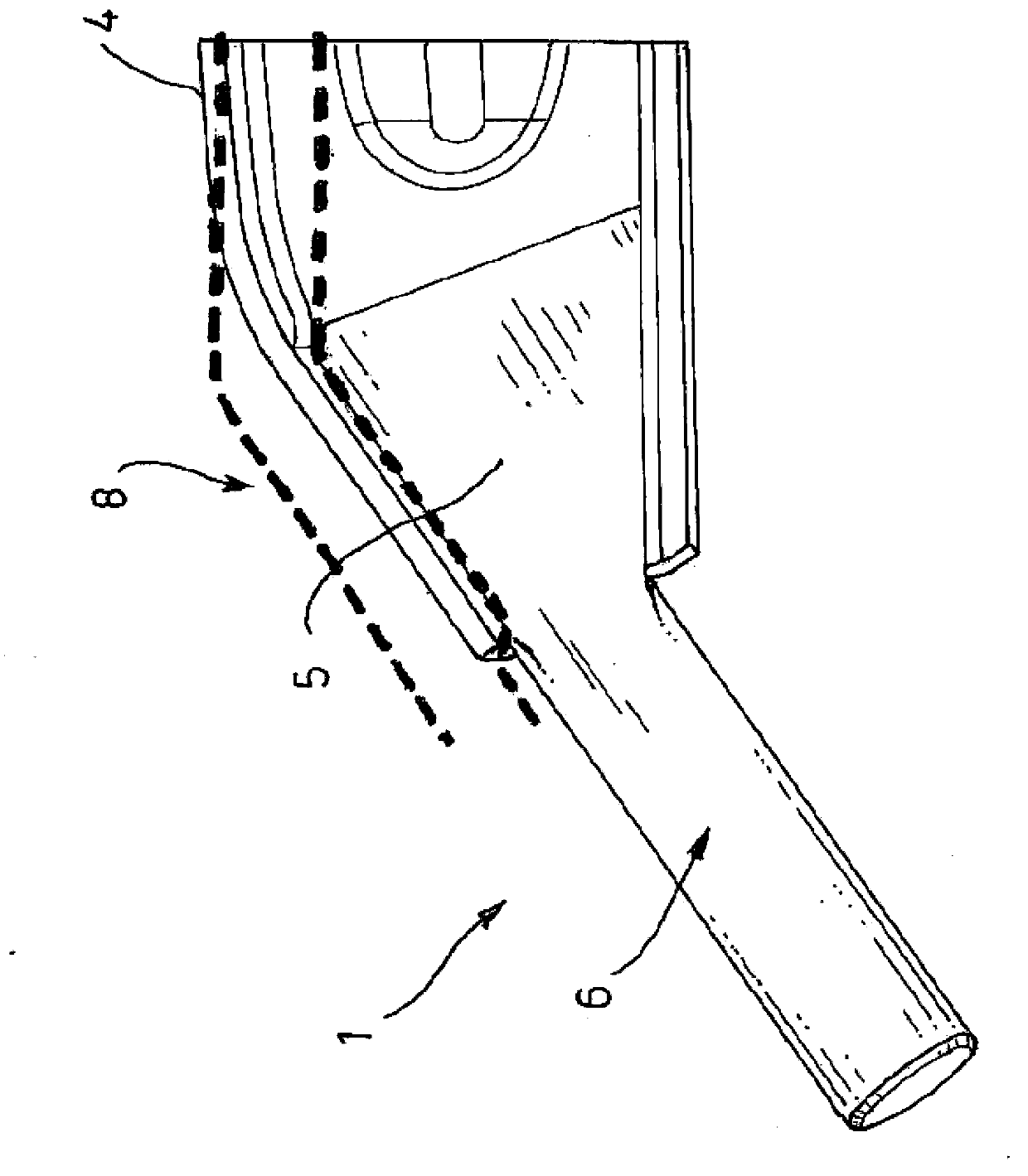

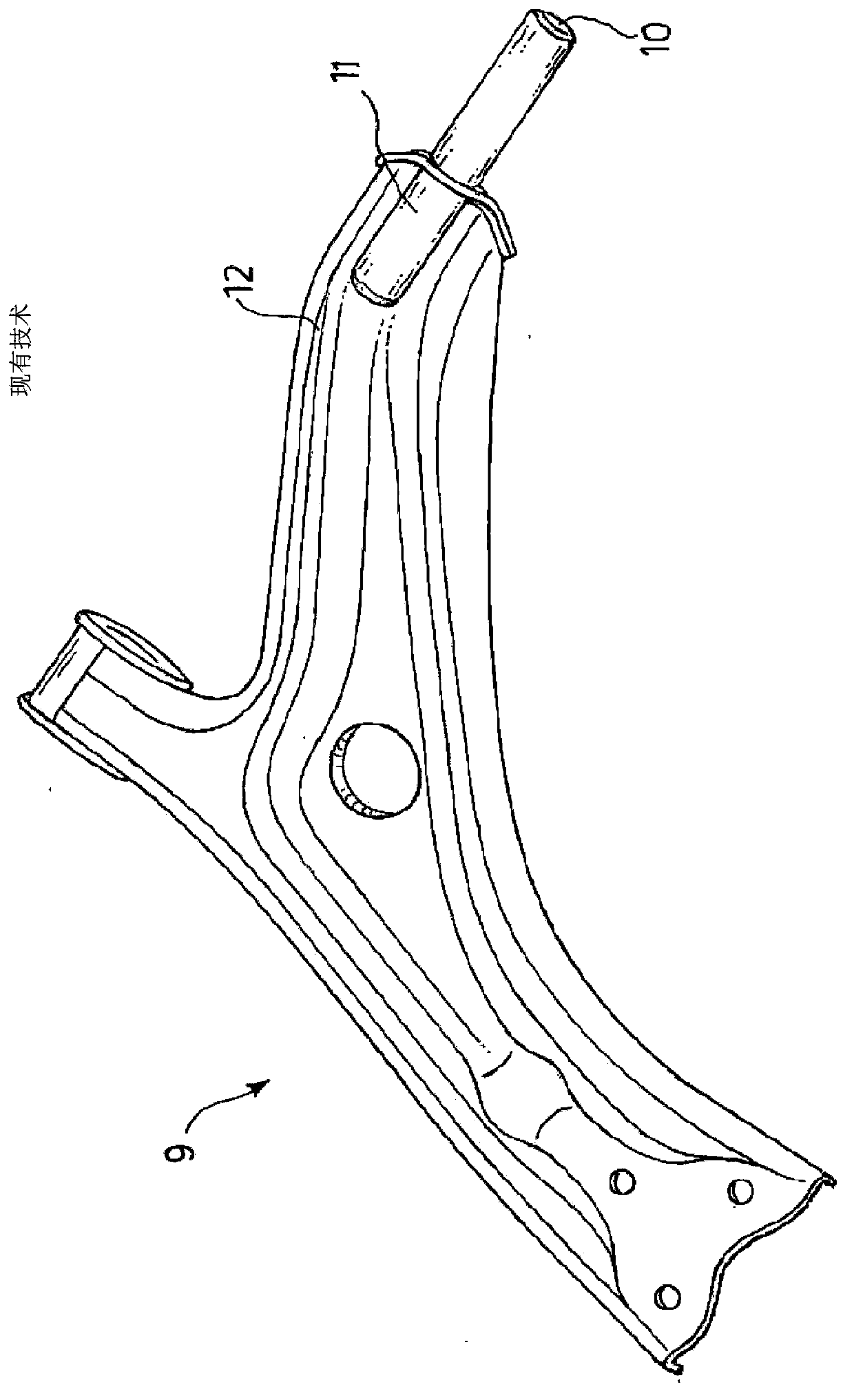

[0040] figure 1 A perspective view of an exemplary embodiment of a transverse link 1 in the form of a monocoque according to the invention is shown. The transverse link 1 has a connection leg 2 for connection to a body (not shown) and a wheel leg 3 for connection to a wheel carrier (also not shown). In this regard, figure 1 The connecting leg 2 and the wheel leg 3 in the transverse link 1 shown in are formed substantially in an L-shape. The connection leg 2 has a connection point 4 to which an anchor 5 of a substantially pin-shaped bearing journal 6 can be connected in a positionally secure manner. From figure 1 It can likewise be seen in the figure that the connecting leg 2 has a recess 7 in the region of the connecting point 4 . The notch 7 is used to allow from figure 1 The side (upper side) of the transverse link 1 shown enters the anchor 5 of the bearing journal 6 located below it, so that this anchor 5 can also be welded from the upper side of the transverse lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com