Flame-proof pouring material and launder prefabricated component for copper anode furnace

A technology of refractory castables and copper anodes, applied in the field of refractory castables, can solve the problems of high cost of use, short service life of ramming materials, and easy peeling, etc., and achieve good high temperature erosion resistance and excellent thermal shock resistance , The effect of saving baking cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

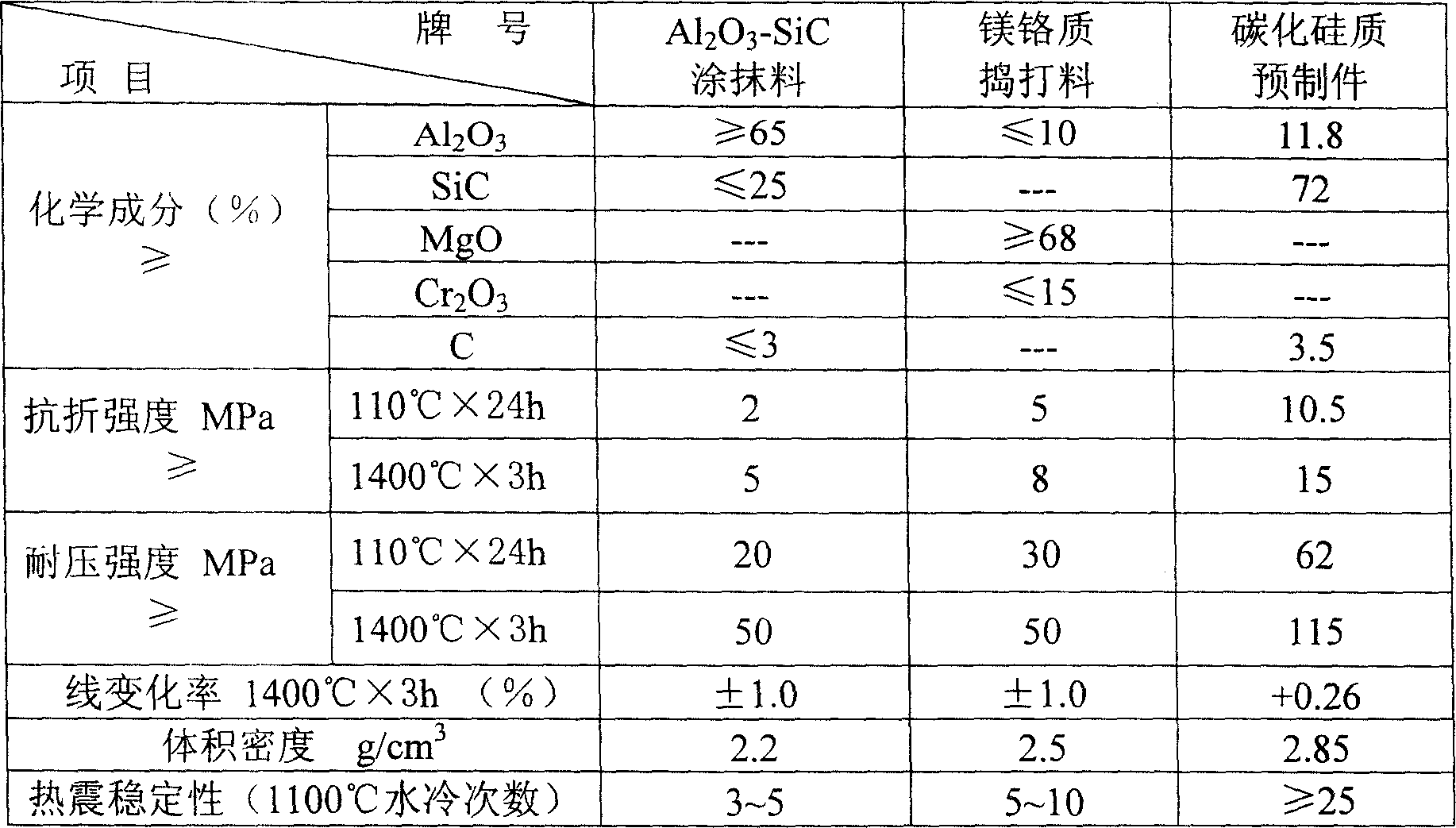

[0022] Embodiment 1: refractory castable for launder of copper anode furnace, made of 75wt% SiC, 3wt% Al 2 o 3 Micropowder, 3wt% SiO 2 Powder, 8wt% mullite powder, 2wt% asphalt, 2wt% electrode powder, 3wt% Si, 4wt% cement binder, plus 0.1wt% sodium tripolyphosphate, the measured chemical composition of the castable: SiC 73.5wt% , Al 2 o 3 11.8wt%, SiO 2 5.8wt%, C 3.5wt%, CaO 1.5wt%, and other impurities.

Embodiment 2

[0023] Embodiment 2: refractory castable for launder of copper anode furnace, by 64.5wt% SiC, 18wt% corundum, 4wt% SiO 2 Micropowder, 6wt% mullite powder, 1wt% bitumen, 2.5wt% electrode powder, 2wt% Si, 2wt% cement binder, plus 0.06wt% sodium tripolyphosphate, 0.1wt% sodium hexametaphosphate, measured Castable chemical composition: SiC63.5wt%, Al 2 o 3 24.8wt%, SiO 2 6.5wt%, C 3wt%, CaO 0.8wt%, and other impurities.

Embodiment 3

[0024] Example 3: Refractory castable for launder of copper anode furnace, 50wt% SiC, 20wt% super bauxite, 11wt% corundum, 5wt% Al 2 o 3 Micropowder, 2wt% SiO 2 Micro powder, 4wt% mullite powder, 3wt% electrode powder, 2wt% Si, 3wt% cement binder, plus 0.12wt% sodium hexametaphosphate, the measured chemical composition of the castable: SiC 48.5wt%, Al 2 o 3 38wt%, SiO 2 7.2wt%, C 2.5wt%, CaO 1.0wt%, and other impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com