Vertical offcenter crusher and its operation method

A vertical centrifuge and crusher technology, applied in grain processing and other directions, can solve problems such as strong impact force on raw materials that cannot be crushed, reduced crushing processing capacity, and inability to effectively crush, and achieves maintenance operations in a short time and at a favorable cost. , maintenance cost favorable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

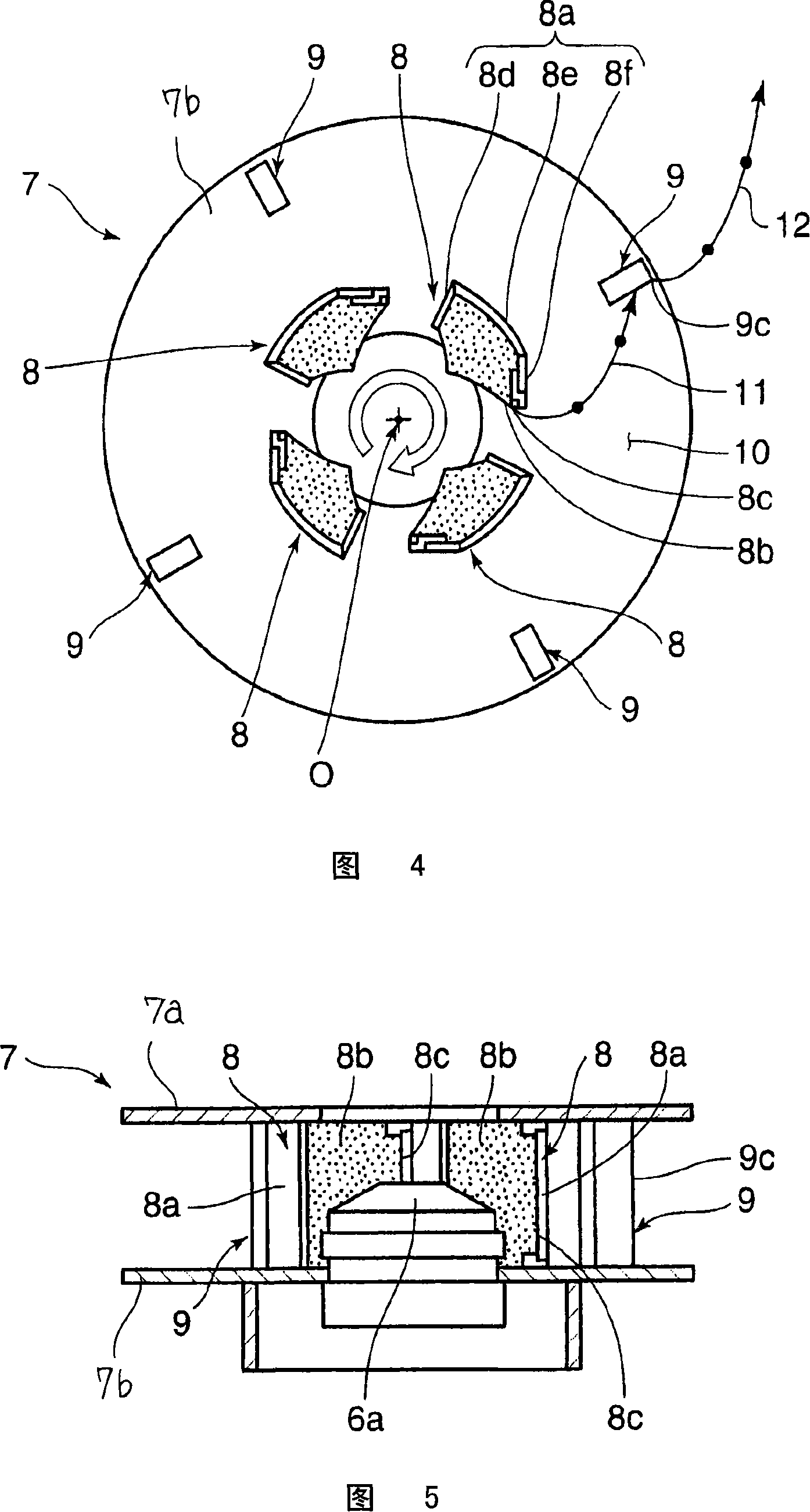

[0030] The vertical centrifugal crushers according to Embodiments 1 and 2 of the present invention which implement the operating method of the vertical centrifugal crusher according to the present invention will be described below with reference to the accompanying drawings. However, this is only one embodiment of the present invention, and the present invention is not limited thereto.

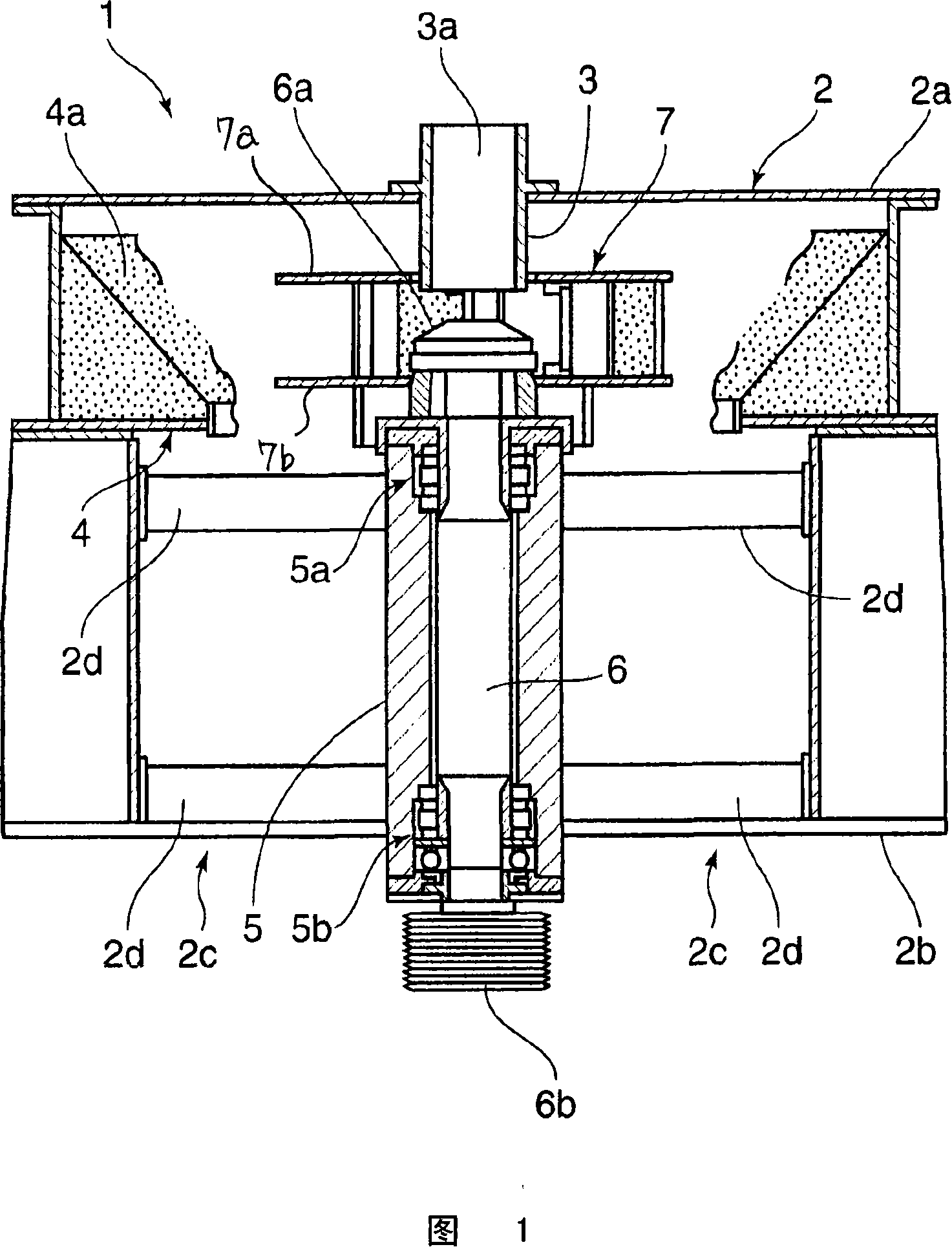

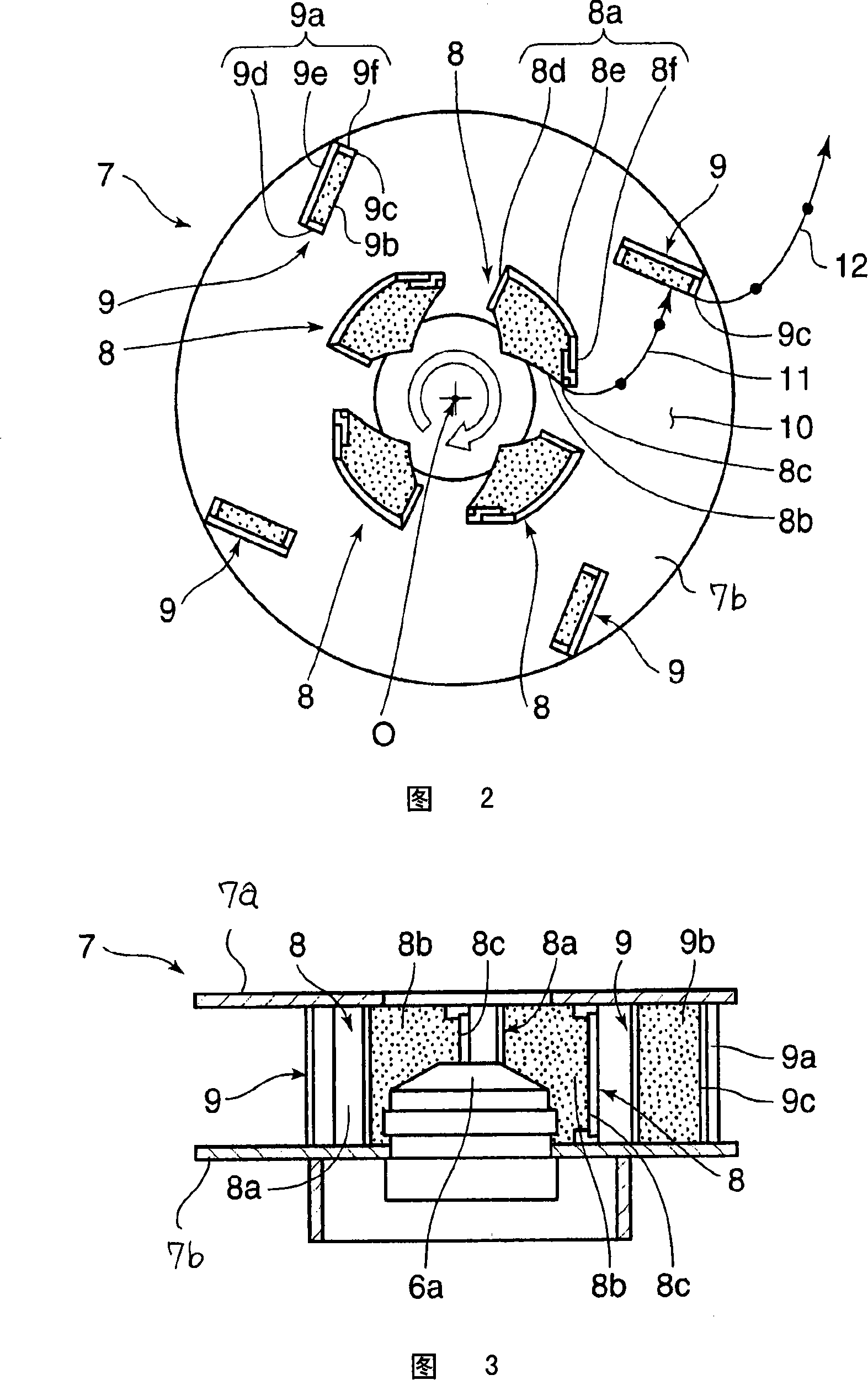

[0031] First, a vertical centrifugal crusher according to Embodiment 1 of the present invention will be described with reference to FIG. 1 , which is a longitudinal sectional view, FIG. 2 , which is a transverse sectional view of the rotor, and FIG. 3 , which is a longitudinal sectional view of the rotor.

[0032] Reference numeral 1 shown in FIG. 1 is a vertical centrifugal crusher according to Embodiment 1 of the present invention. This vertical centrifugal crusher 1 includes a crusher main body 2 having a structure described later. The crusher main body 2 includes an upper casing 2a and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com