Coupler, and fuel cell and fuel cartridge using the coupler

A fuel cell and coupling technology, applied in fuel cells, fuel cell additives, couplings, etc., can solve the problems of electrode film structure degradation, and achieve the effect of preventing output degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

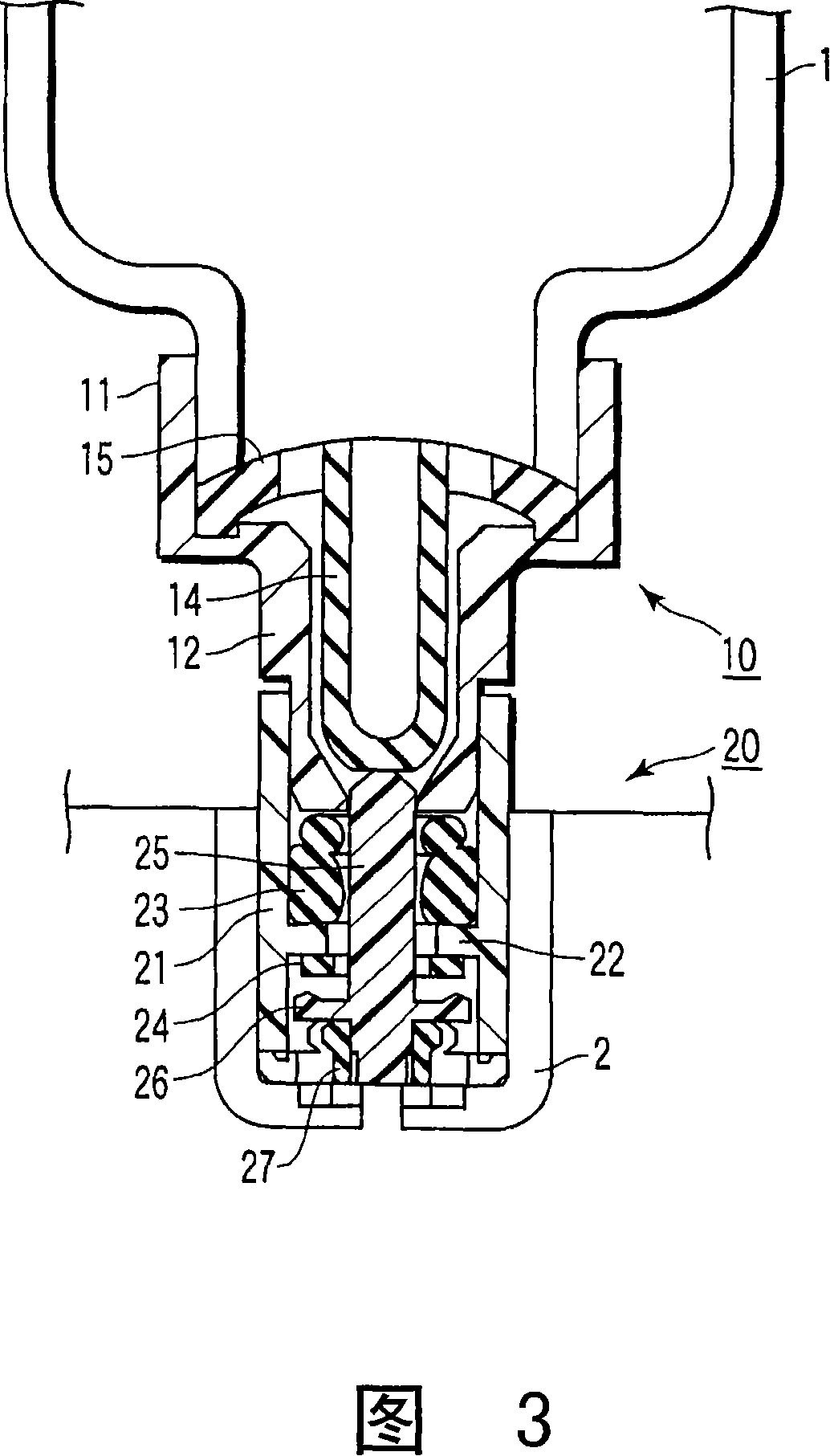

[0057] Figures 2 and 3 depict a first embodiment of the coupling of the present invention. Wherein, Fig. 2 shows the state of the coupling before it is assembled, and Fig. 3 shows the state of the coupling after it is assembled. This coupling can be used on passive fuel cells for coupling a fuel cartridge to a fuel container mounted on the fuel cell body.

[0058] In these figures, 10 denotes the nozzle, 20 denotes the socket, 11 denotes the nozzle body, 12 denotes the nozzle head, 13 denotes the nozzle outlet, 14 denotes the movable pin, 15 denotes the first supporting member, 21 denotes the housing, 22 is an annular flange, 23 is a sleeve, 24 is an annular gasket, 25 is a valve stem, 26 is a valve head, and 27 is a second supporting member.

[0059] This coupling consists of a nozzle 10 and a socket 20 . The nozzle 10 is designed to be connected to the mouth of the bottle-shaped fuel cylinder 1 , and the socket 20 is designed to be connected to the inlet 2 of the fuel cont...

no. 2 example

[0075] 5 and 6 show another embodiment of the coupling of the present invention. Wherein Fig. 5 shows the coupling is in its state before assembly, and Fig. 6 shows the coupling is in its state after assembly. In FIGS. 5 and 6, 31 denotes a nozzle body, 33 is a nozzle opening, and 34 is an elastic ball.

[0076] This example differs from the above example shown in FIGS. 2 and 3 mainly in that the movable pin 14 and the first support member 15 of the previous example are replaced by elastic balls 34 in this example. As for the configuration of the socket 20 in this example, it is basically the same as in the previous example. Therefore, the same parts as those in the previous example are given the same reference numerals in this example, and thus their explanations are also omitted.

[0077] In this example, the main part of the nozzle 10 is constituted by the nozzle body 31 and the elastic ball 34 . The distal end of the nozzle body 31 is provided with a nozzle opening 33 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com