Synthesizing method for urea

A urea and synthesis tower technology is applied in the field of traditional urea synthesis systems to achieve uniform distribution of gas and liquid, avoid back mixing and avoid reversible reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

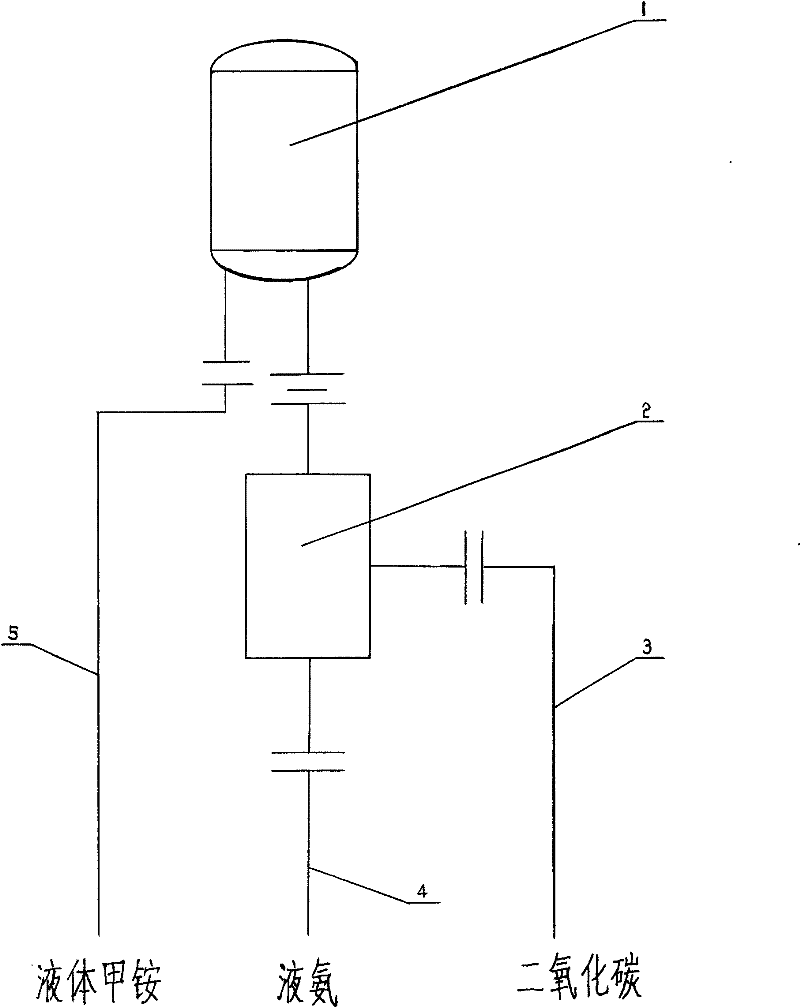

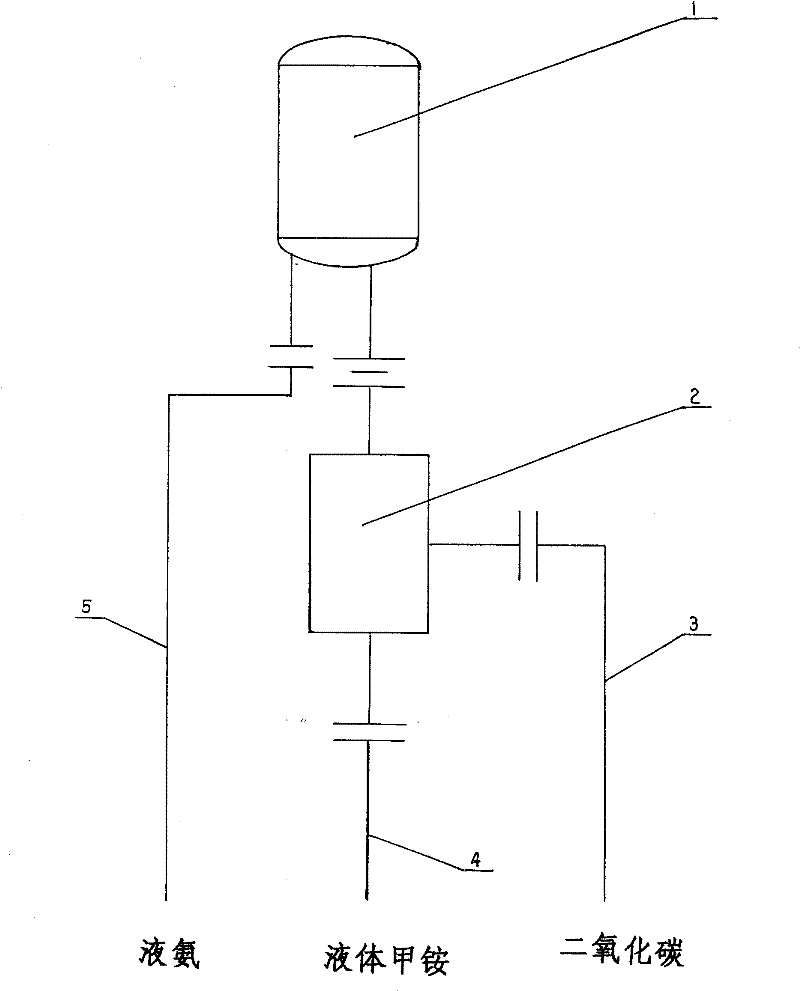

[0053] Depend on figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the high-pressure liquid-gas tube type rapid mixing reactor 2 is adopted to make the three materials entering the urea synthesis tower 1: liquid ammonia 3, gaseous carbon dioxide 4, liquid methylammonium 5 or any two of them become a completely uniform The liquid-gas mixture then enters the synthesis tower. The high-pressure liquid-gas tube type rapid mixing reactor 2 can atomize liquid ammonia and liquid methylammonium separately or simultaneously into 100-250 μm mist droplets (instead of liquid droplets) and then mix them with gaseous carbon dioxide to form a uniform two-phase flow. Solve the liquid-gas mixing problem that enters synthetic tower effectively, thereby realize each effect of the present invention.

[0054] The high-pressure liquid-gas tubular fast mixing reactor 2 is connected to the synthesis tower 1 through flange 21, flange 11, and high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com