Slurry extruding method of disposable tableware produced by magnesia oxychloride cement

A magnesium oxychloride cement, a disposable technology, is applied in the field of pulping and extrusion of magnesium oxychloride cement disposable tableware, which can solve the problem of short initial setting time of magnesium oxychloride cement, high slurry viscosity, affecting the strength and durability of disposable tableware. Appearance and other problems, to achieve the effect of controllable extrusion slurry time and simple extrusion slurry process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

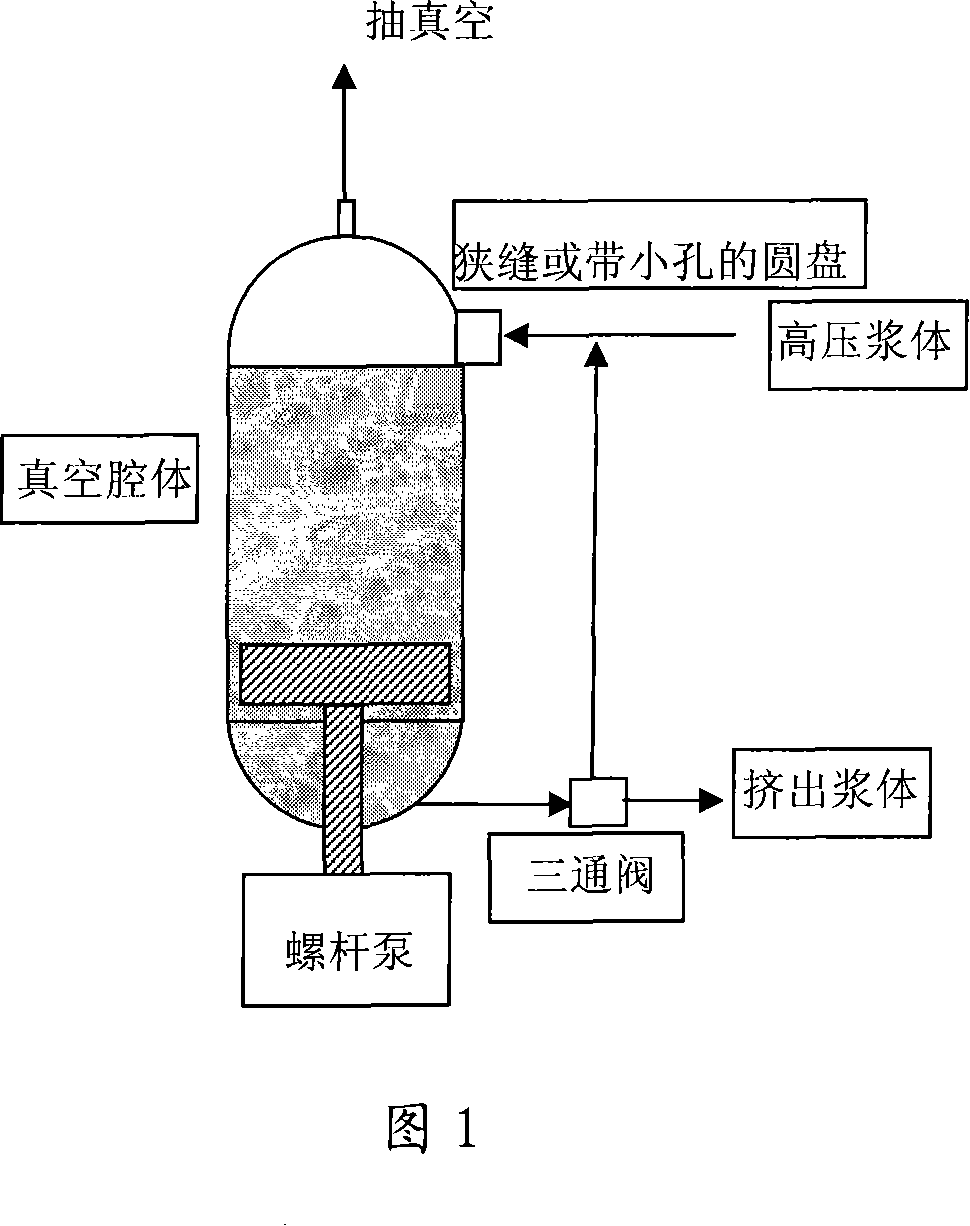

[0014] Using its own weight, the magnesium oxychloride cement slurry can also be boosted to 0.5MPa with a slurry pump, squeezed into a cavity through a slit with a diameter of 10mm, and vacuumed from the top of the cavity with a vacuum degree of 0.08MPa. A screw pump is installed at the bottom of the body, and the magnesium oxychloride cement slurry in the vacuum chamber is extruded through the screw pump. A three-way valve is installed at the extrusion port of the screw pump, and the extrusion time of the magnesium oxychloride cement slurry is controlled by controlling the three-way valve. , when there is no need for the slurry to be extruded from the extrusion port, the slurry will flow back to the slurry inlet of the cavity through the three-way valve.

Embodiment 2

[0016] The magnesium oxychloride cement slurry can also be boosted to 10MPa with a slurry pump by its own weight, and squeezed into a cavity through a disc with a small hole. The diameter of the small hole is 5mm, and the number of small holes on the disc is 10, vacuumize from the top of the cavity, the vacuum degree is 0.04MPa, and a screw pump is installed at the bottom, through which the magnesium oxychloride cement slurry in the vacuum cavity is extruded, and a three-way valve is installed at the outlet of the screw pump , by controlling the three-way valve to control the extrusion time of the magnesium oxychloride cement slurry, when there is no need for the slurry to be extruded from the extrusion port, the slurry can flow back to the slurry inlet of the cavity through the three-way valve.

Embodiment 3

[0018] Using its own weight, the magnesium oxychloride cement slurry can also be boosted to 1MPa with a slurry pump, and squeezed into a cavity through a disc with small holes. The diameter of the small hole is 1mm, and the number of small holes on the disc is 20. One, vacuumize from the top of the cavity, the vacuum degree is 0.09MPa, a screw pump is installed at the bottom, and the magnesium oxychloride cement slurry in the vacuum cavity is extruded through the screw pump, and a three-way valve is installed at the outlet of the screw pump. By controlling the three-way valve to control the extrusion time of the magnesium oxychloride cement slurry, when there is no need for the slurry to be extruded from the extrusion port, the slurry can flow back to the slurry inlet of the cavity through the three-way valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com