Liquid crystal mixture for macromolecule orientation working procedure and liquid crystal display device

A technology of liquid crystal compounds and mixtures, applied in liquid crystal materials, optics, instruments, etc., can solve the problems of long response time, affecting the quality of liquid crystal display panels, and high rotational viscosity of liquid crystal materials, so as to improve the overall process cost and display quality. , the effect of good liquid crystal alignment function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

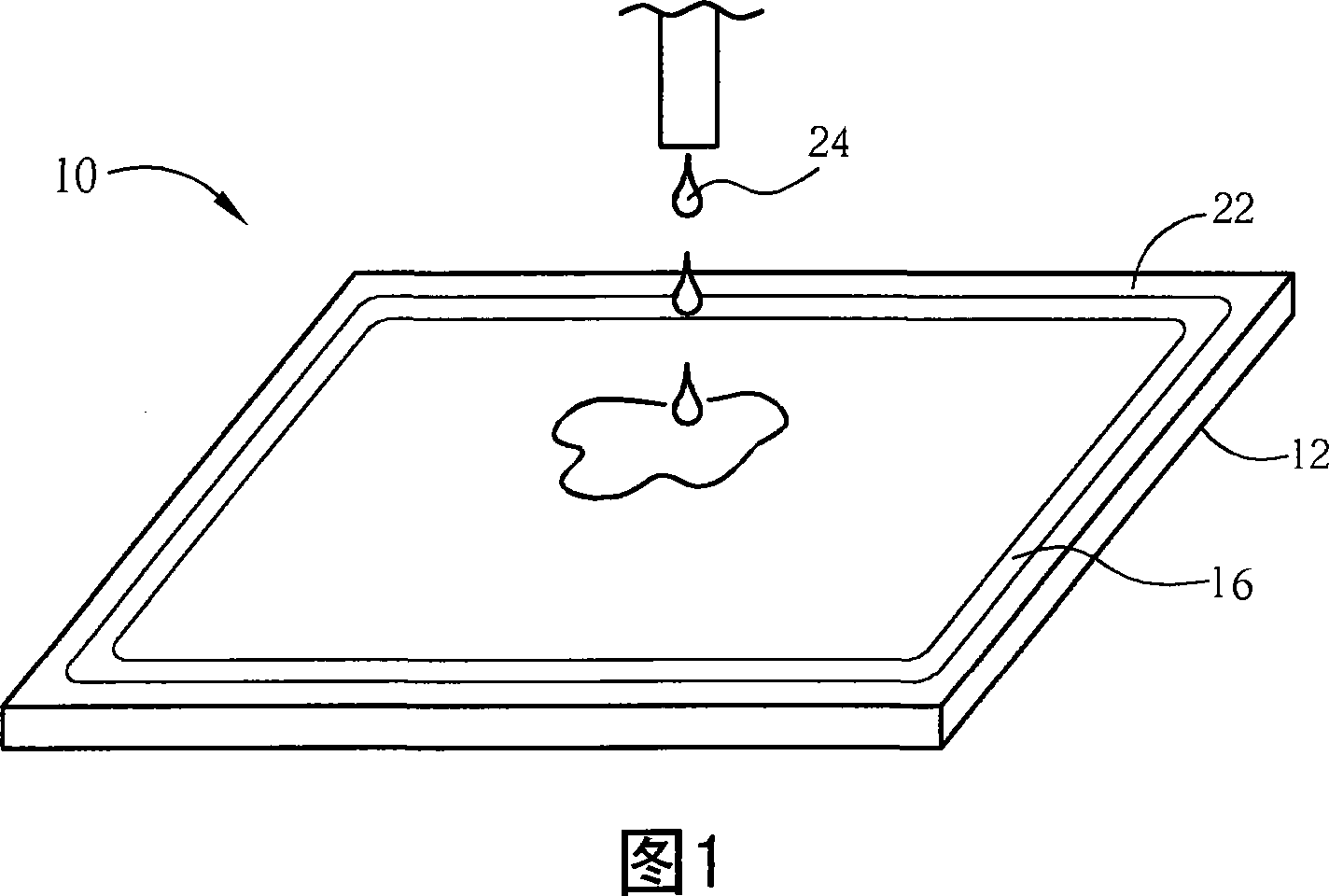

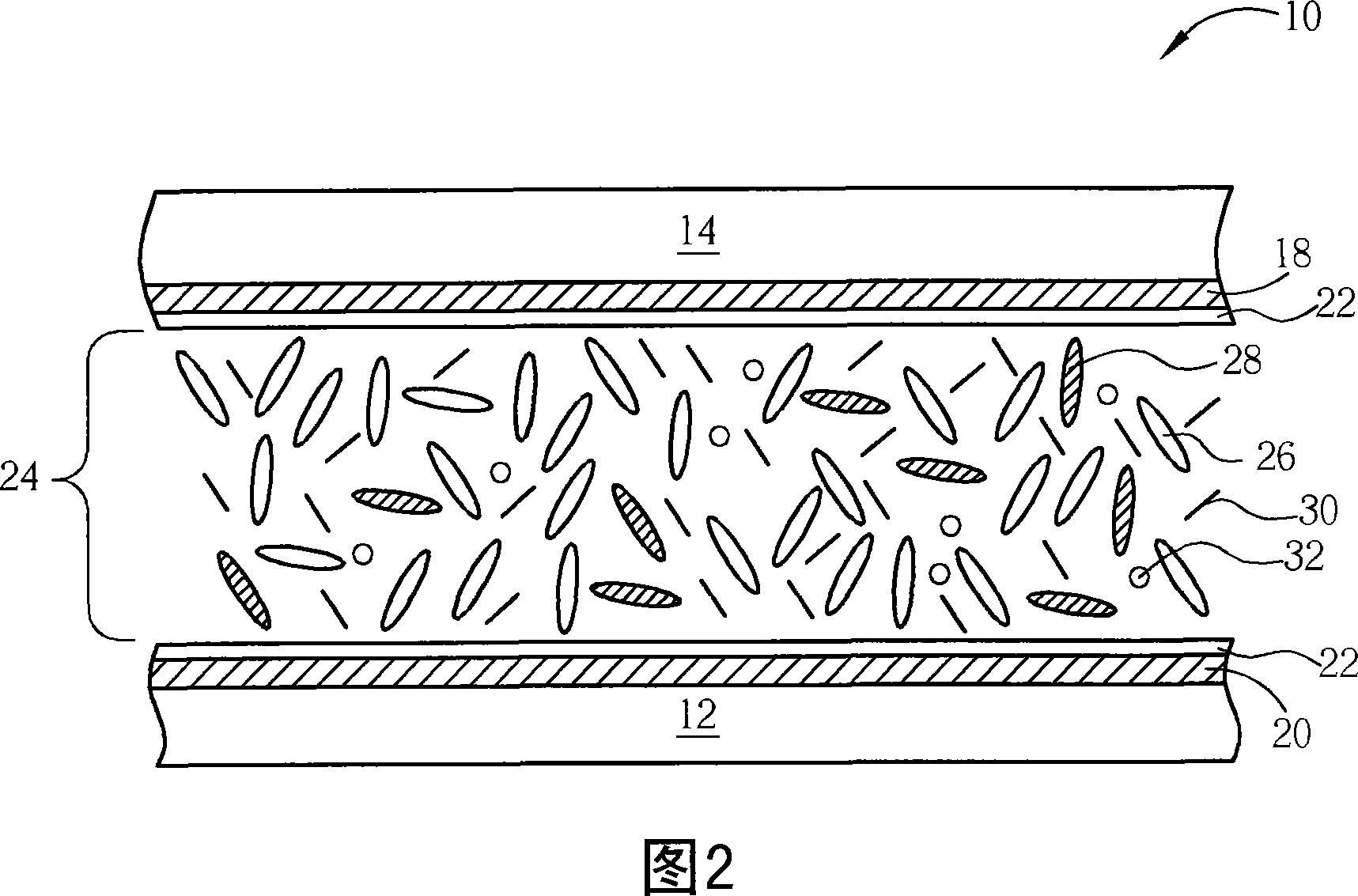

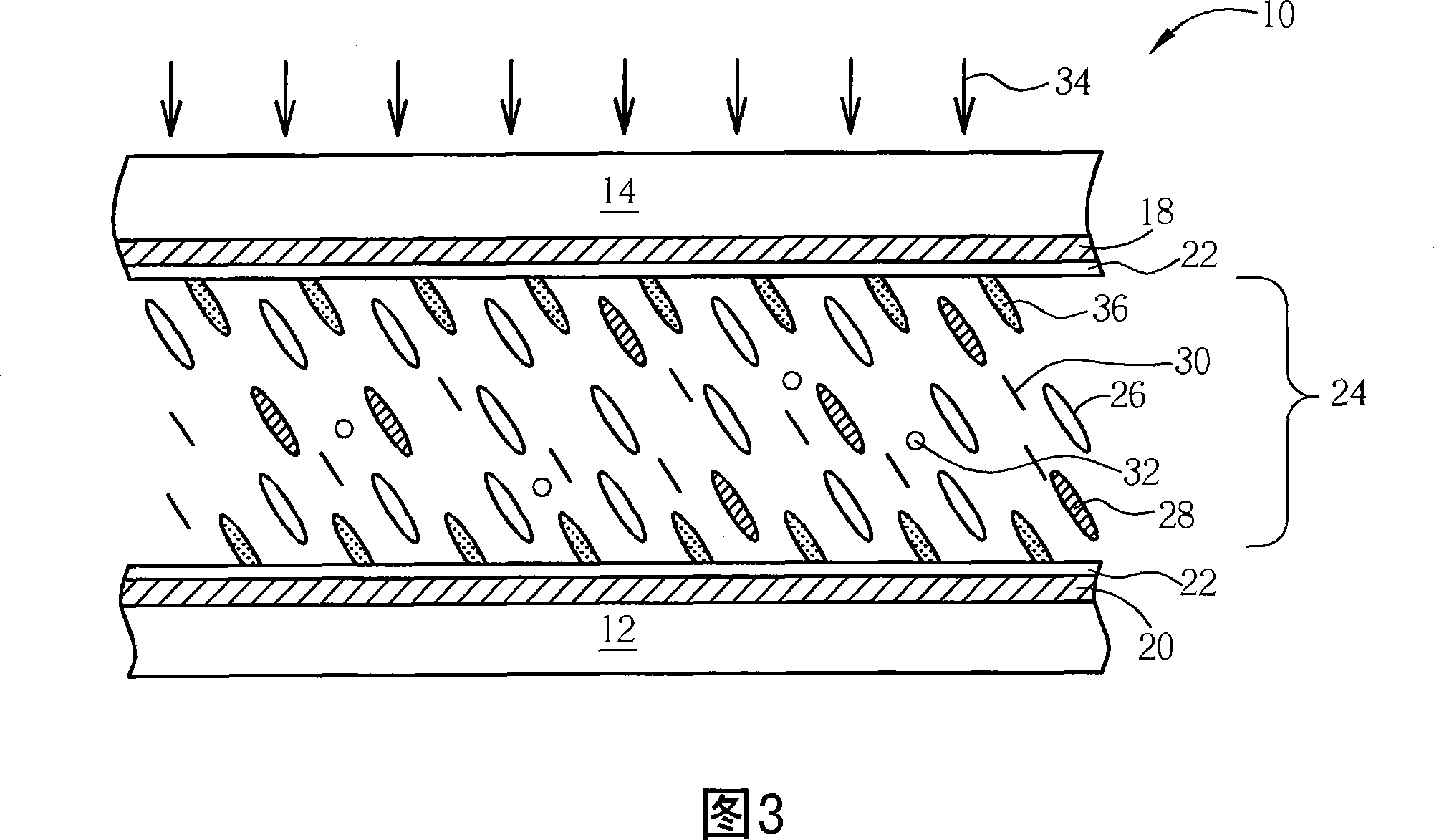

[0019] Please refer to FIG. 1 to FIG. 3 . FIG. 1 to FIG. 3 are schematic diagrams of the process of applying the liquid crystal mixture of the present invention to a liquid crystal display panel 10 . As shown in FIG. 1, two transparent substrates are firstly provided as the lower substrate 12 and the upper substrate 14 of the liquid crystal display panel 10 (shown in FIG. 2), wherein the upper surface of the lower substrate 12 may include thin film transistors, driving chips and scanning lines. , signal lines and other electronic components (not shown), and the lower surface of the upper substrate 14 may include color filters (not shown). After the upper substrate 14 and the lower substrate 12 are cleaned, the alignment film 22 can be printed on the lower surface and the upper surface respectively, and then the liquid crystal mixture 24 of the present invention is filled on the upper and lower surfaces by using the one drop fill (ODF) method. The substrates 14 and 12 are assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com