System and method for collecting dust in production line

A production line and dust technology, applied in cleaning methods and utensils, chemical instruments and methods, and dust removal, etc., can solve the problems of reducing production efficiency, re-pollution, dust dispersion, etc., and achieve the effect of realizing automation and reducing work intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

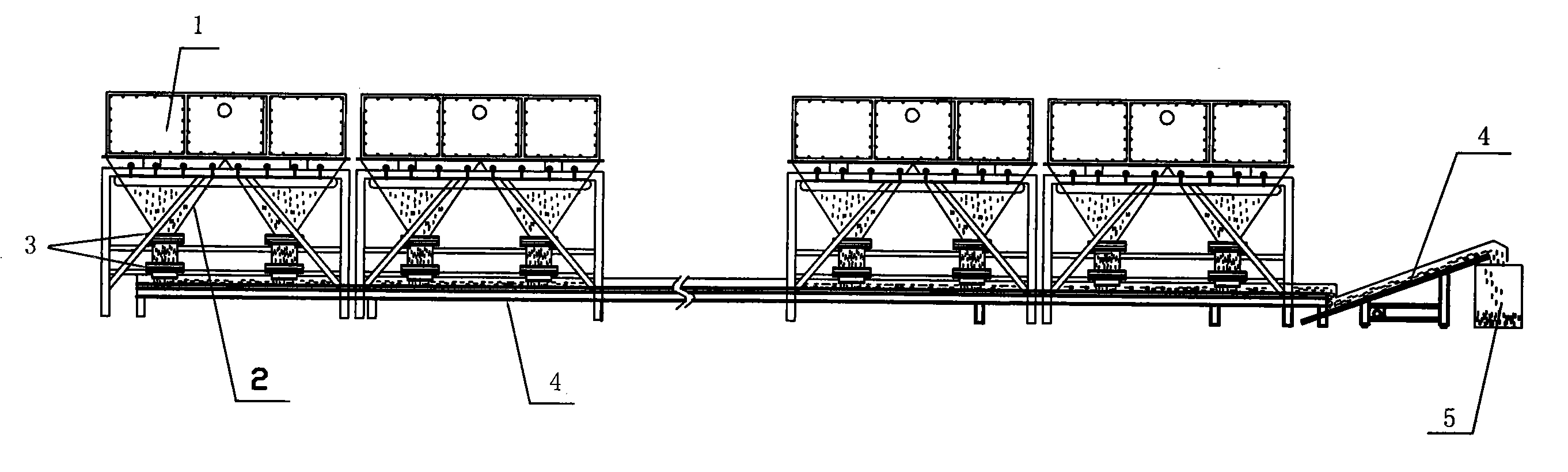

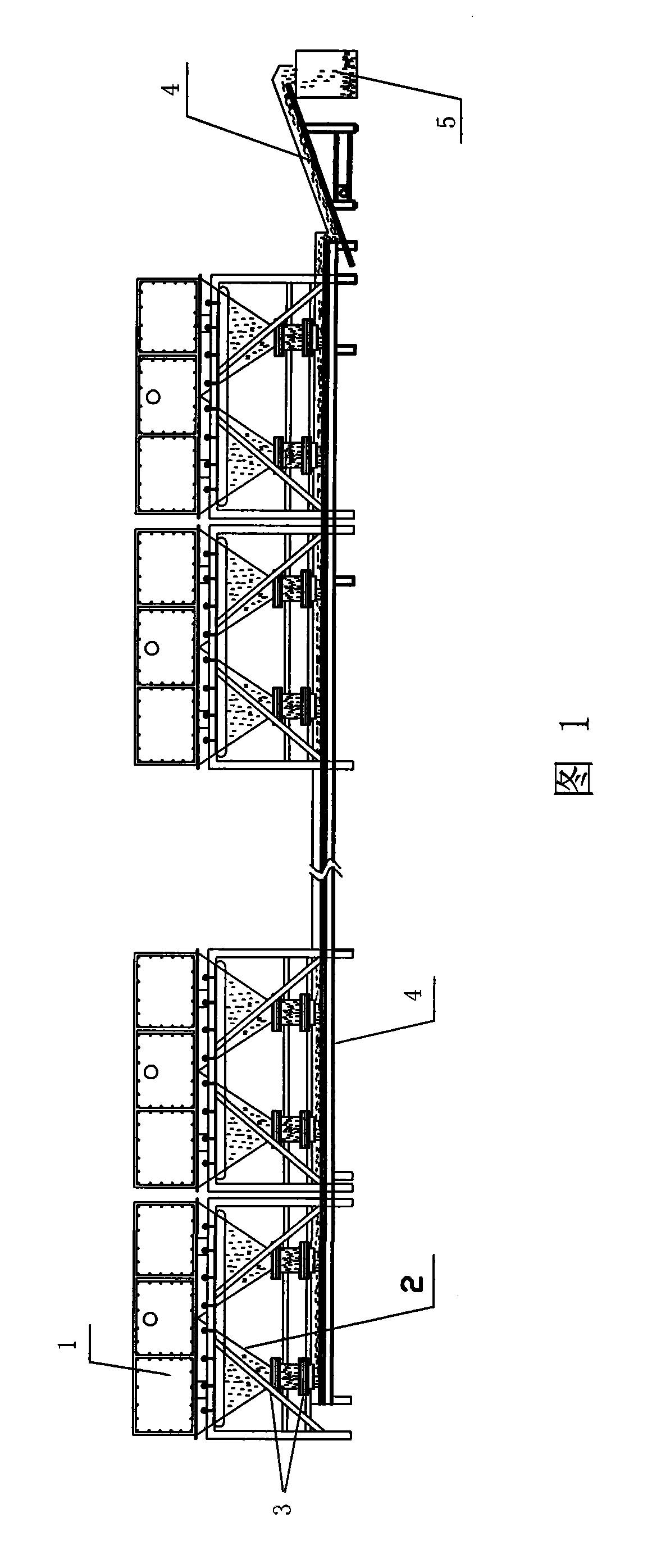

[0016] As shown in FIG. 1 , it is a schematic diagram of a preferred embodiment of the system for collecting dust in the production line of the present invention. Shown in Fig. 1 is a part of a production line, there are a plurality of vacuum cleaners 1 on this production line, respectively corresponding to the same or different processes that generate dust in the production line, and each vacuum cleaner 1 is correspondingly provided with a collector In the dust box 2, the dust is sucked into the dust collector 1 by the production line and falls into the dust box 2 after being filtered. Each dust collection box is connected with an automatic control valve, which can be set to be opened at regular intervals. When opened, the dust in the dust collection box will fall into the dust conveying channel, which can realize the function of regularly conveying dust. Or, an automatic detector is set in the dust collection box 2 to detect the amount of dust in the dust collection box, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com