Pasteurized milk enriching calcoblast milk protein and its production method

A milk protein and pasteurization technology, applied in dairy products, milk preparations, applications, etc., can solve problems such as inability to guarantee physiological activity, and achieve the effect of enriching nutrition and benefiting bones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The invention consists of cow's milk and bone-forming milk protein (OMP), wherein the bone-forming milk protein (OMP) accounts for 0.01% by weight, and the rest is milk.

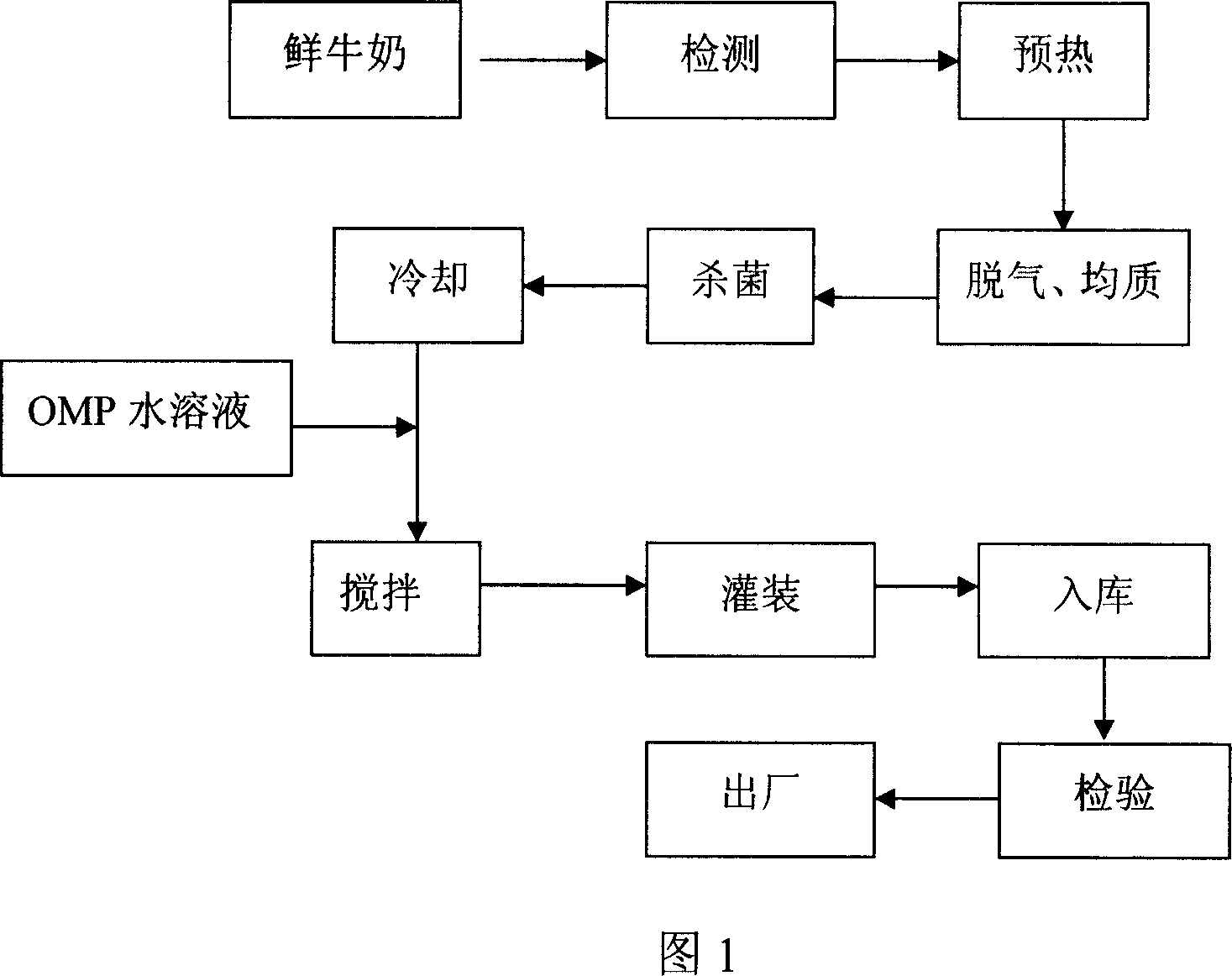

[0027] The production method of the present invention includes the steps of: preheating, homogenizing, sterilizing, cooling, and entering the pasteurized milk storage tank after the raw milk is cooled, and entering the pasteurized milk storage tank after the cooling of the milk is completed. In the process of tanking, bone-building milk protein is added to pasteurized milk, and then enters the pasteurized milk storage tank; in the process of step milk cooling, bone-making milk protein dissolved in sterile water is added to pasteurization In the milk, then enter the pasteurized milk storage tank; add bone-forming milk protein into the pasteurized milk in the step, and enter the pasteurized milk storage tank and stir for 15 seconds; add bone-forming milk protein (OMP) into the pasteurized milk in the ste...

Embodiment 2

[0036] The difference from the examples is that it consists of cow's milk and bone-forming milk protein (OMP), wherein the bone-forming milk protein (OMP) accounts for 0.015% by weight, and the rest is milk.

Embodiment 3

[0038] The difference from Example 1 or 2 is that it consists of cow's milk and bone-forming milk protein (OMP), wherein the bone-forming milk protein (OMP) accounts for 0.015% by weight, and the rest is milk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com