Double helix water stream barrel type high-efficiency coolers

A double helix, cooler technology, applied in the direction of heat exchanger type, indirect heat exchanger, fixed tubular duct assembly, etc., can solve the problems of poor spiral flow effect of cooling water, low heat exchange efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

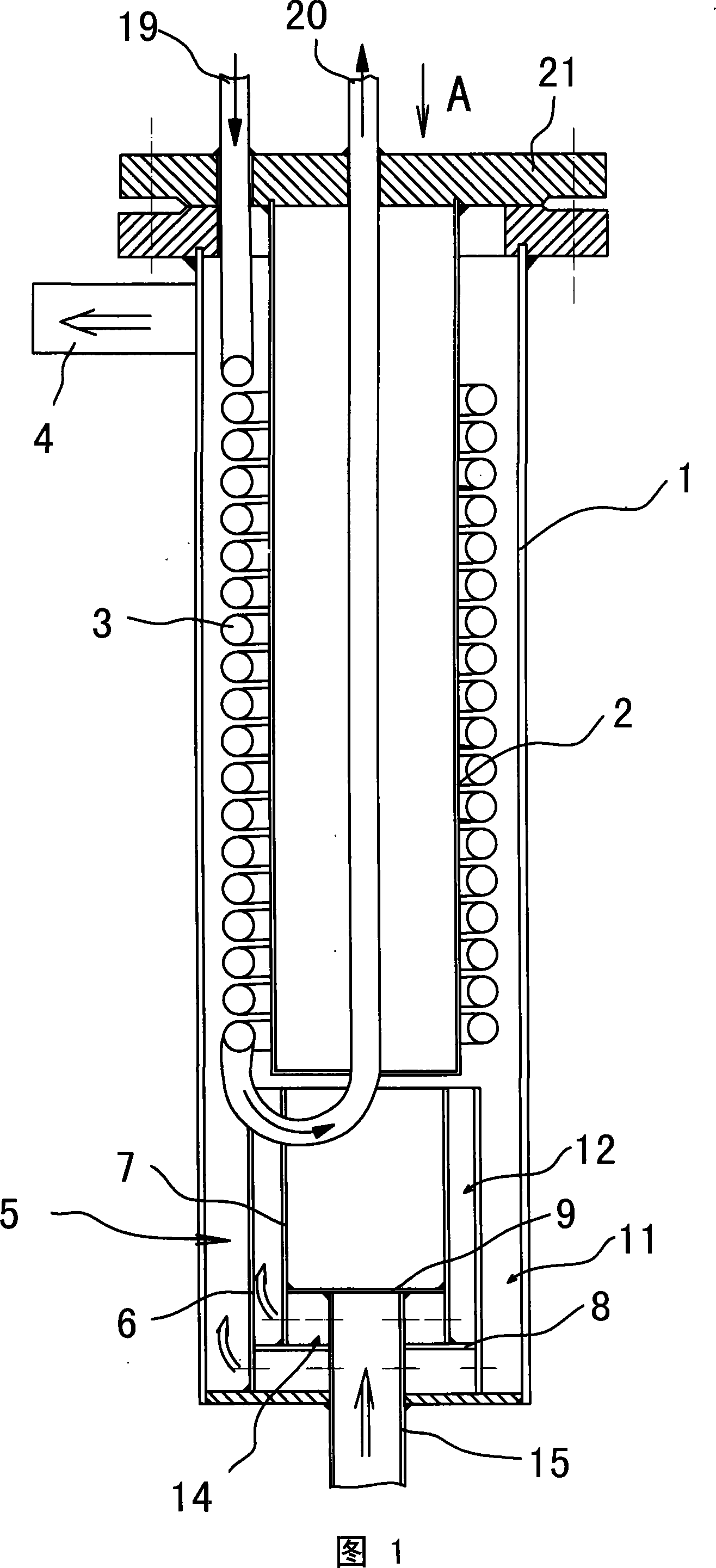

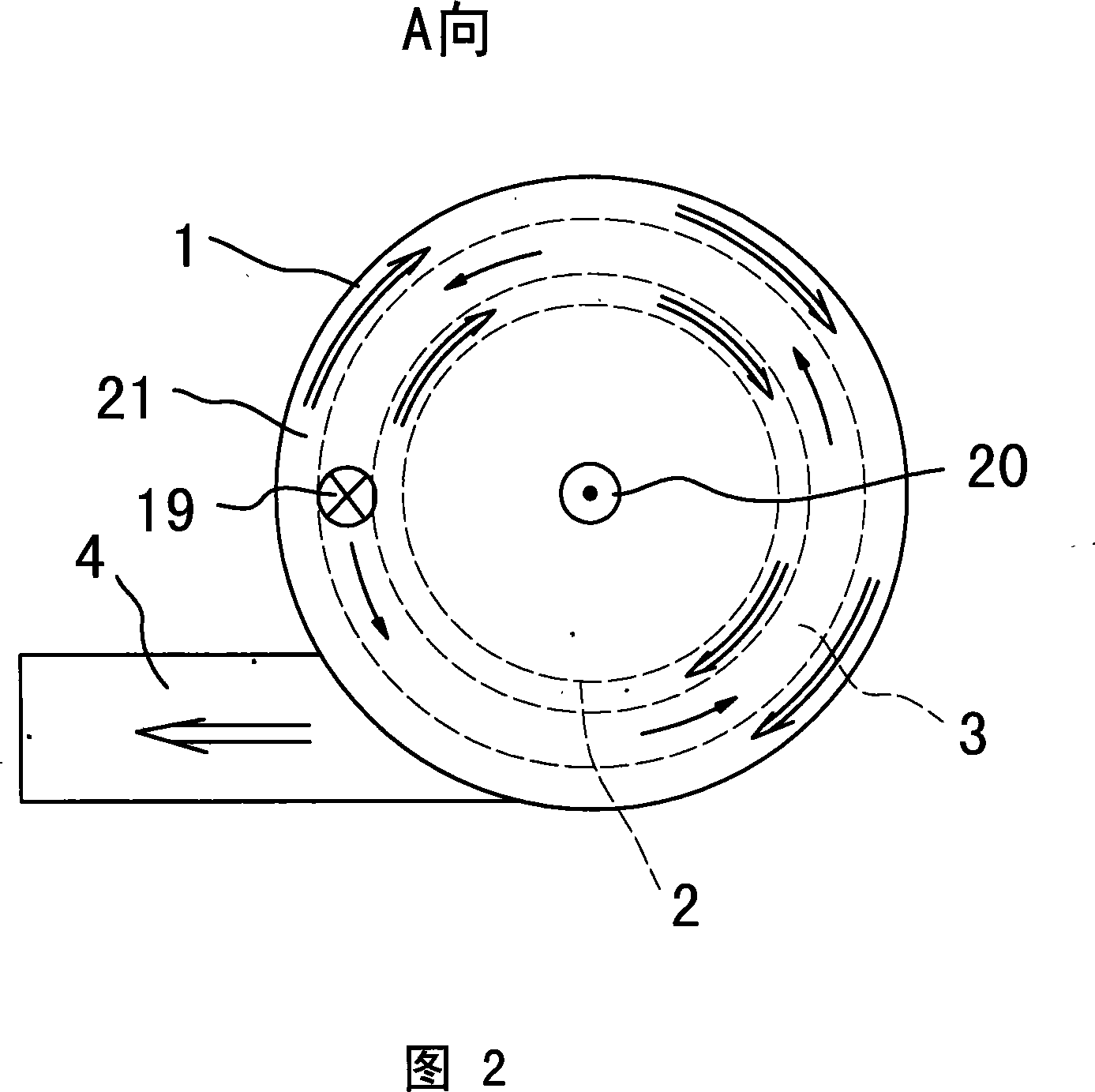

[0030] Embodiment: See accompanying drawing 1, shown in accompanying drawing 2, a kind of double-helix water flow cylinder type high-efficiency cooler comprises a closed cylinder 1, a closed inner sleeve 2 placed in the center of the cylinder 1, placed The spiral tube 3 inside the cylinder 1 and sleeved outside the inner sleeve 2, the two ends of the spiral tube 3 protrude from the cylinder 1, and the cooling water outlet pipe 4 is arranged on the tangential direction of the inner wall surface of the cylinder 1 upper part. The closed inner sleeve 2 is a cylindrical hollow cylinder.

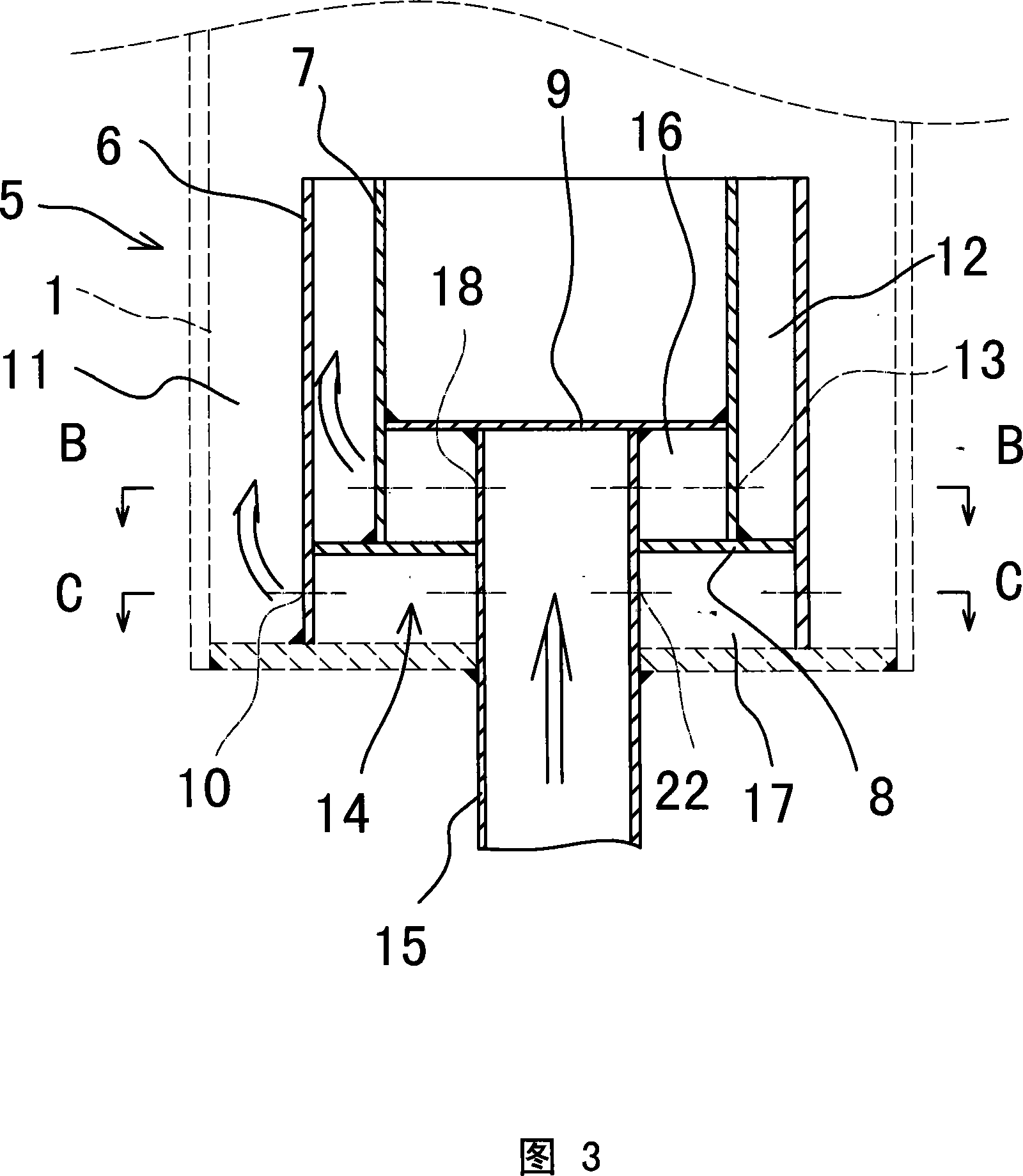

[0031] Referring to accompanying drawing 1, shown in accompanying drawing 3, the inner bottom of described cylindrical body 1 is provided with swirl flow generating device 5 below the helical tube 3 and inner cover 2, and this swirling flow generating device 5 is mainly composed of outer flow guide sleeve 6, The inner guide sleeve 7, the annular partition 8 and the sealing plate 9 are formed.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com