Method and device for forming a top film sheet from a film web

A membrane and sheet technology, which is used in the field of forming top membrane sheets and devices through membranes, can solve problems such as difficulties, time-consuming assembly work, and membranes that cannot be completely cut off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

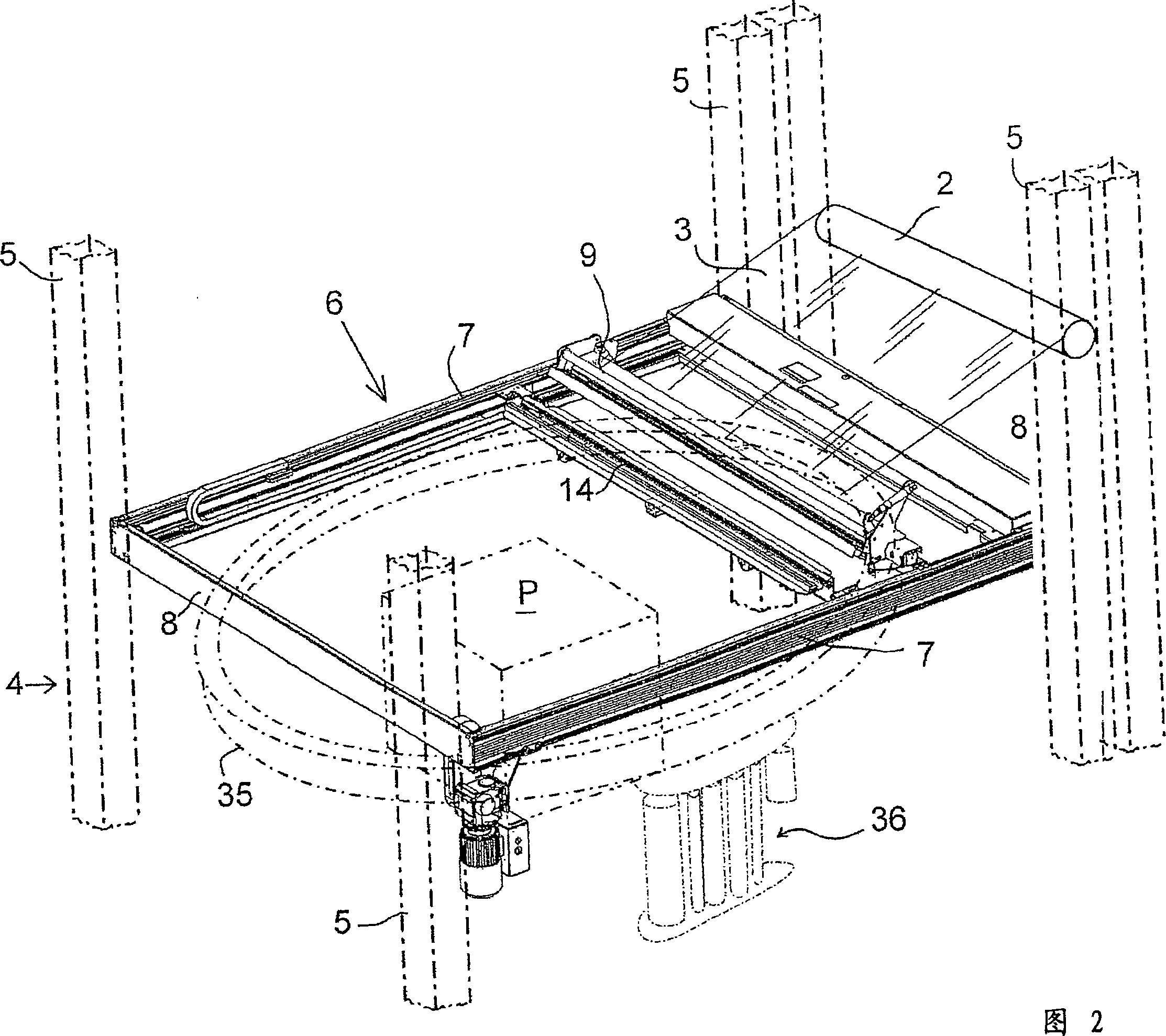

[0045] Figure 2 shows an apparatus that can be used to form a top film sheet 1 from a film 3 wound on a roll 2 and to set the sheet on an object P to be packaged (shown in dashed lines). The objects P to be packaged may be, for example, loading pallets. The plant comprises a machine frame 4 supported on a fixed foundation. The machine frame 4 comprises vertical columns 5 shown in dashed lines in the figure. The device also includes a frame 6 . The frame 6 comprises two parallel guide beams 7 which are arranged at a distance from each other and whose ends are fixed to each other by means of transverse bars 8 to form a rectangular horizontal frame structure. A frame 6 guided by vertical columns 5 is arranged to be movable up and down in the vertical direction by known means not shown. If the device is connected to a conventional packaging machine, the packaging frame 35 can be connected to the frame 6 to guide a film dispenser 36 (film dispenser), wherein the packaging film i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com