Shower head

A nozzle and rotating wheel technology, applied in the direction of spraying device, spraying device, etc., can solve the problem that the nozzle cannot be converted, and achieve the effect of simple installation and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

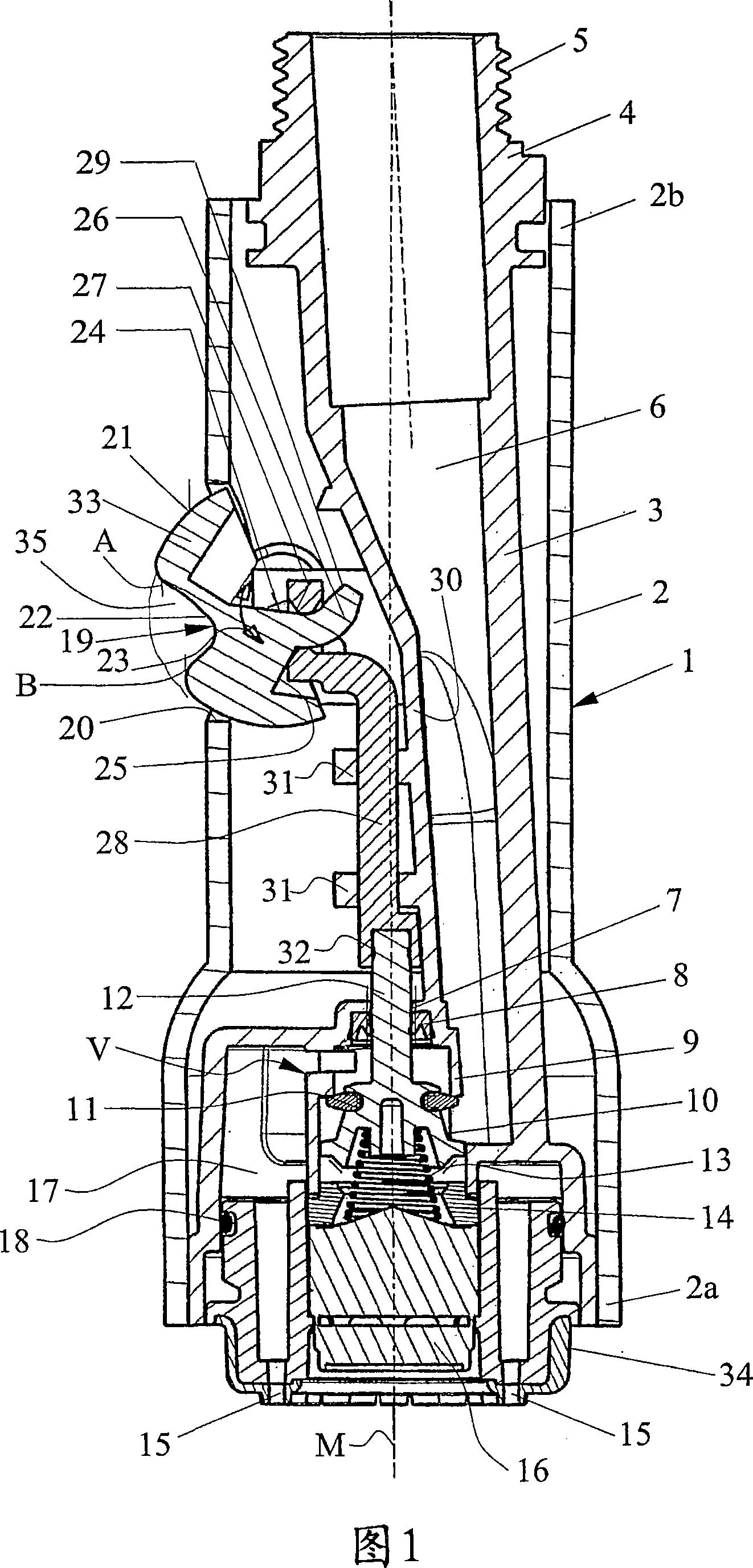

[0029] The spray head 1 shown in FIG. 1 has a substantially cylindrical housing 2 in which a water delivery pipe 3 is mounted. On the edge protruding from the housing 2, the water supply pipe 3 has a connecting pipe 4 with a connecting thread 5, at which connecting pipe the spray head 1 is connected to a hose (not shown here). The hose is preferably pulled out in a pipe bend, not shown here. The spray head 1 can then be pulled out, for example, downwards and used in particular as a dishwashing spray head.

[0030] At the other end of the water supply pipe 3 there is a known insert 34 which is sealed relative to the water supply pipe 3 with a sealing ring 18 and which has a water outlet 15 for spraying water and a flow former 16 in the center. The water flow is formed through the water outlet 15 or through the water flow former 16 . Thus two currents can be formed here. Suitable inserts 34 are known to those skilled in the art and therefore need not be described in detail he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com