Snow melt agent intelligent spreading control system for snow-fighting vehicle

A technology of spreading control and snow melting agent, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of manual control of snow melting agent, insufficient amount of spraying, waste of resources and environment, etc., and achieves high safety and installation. Simple and widely applicable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

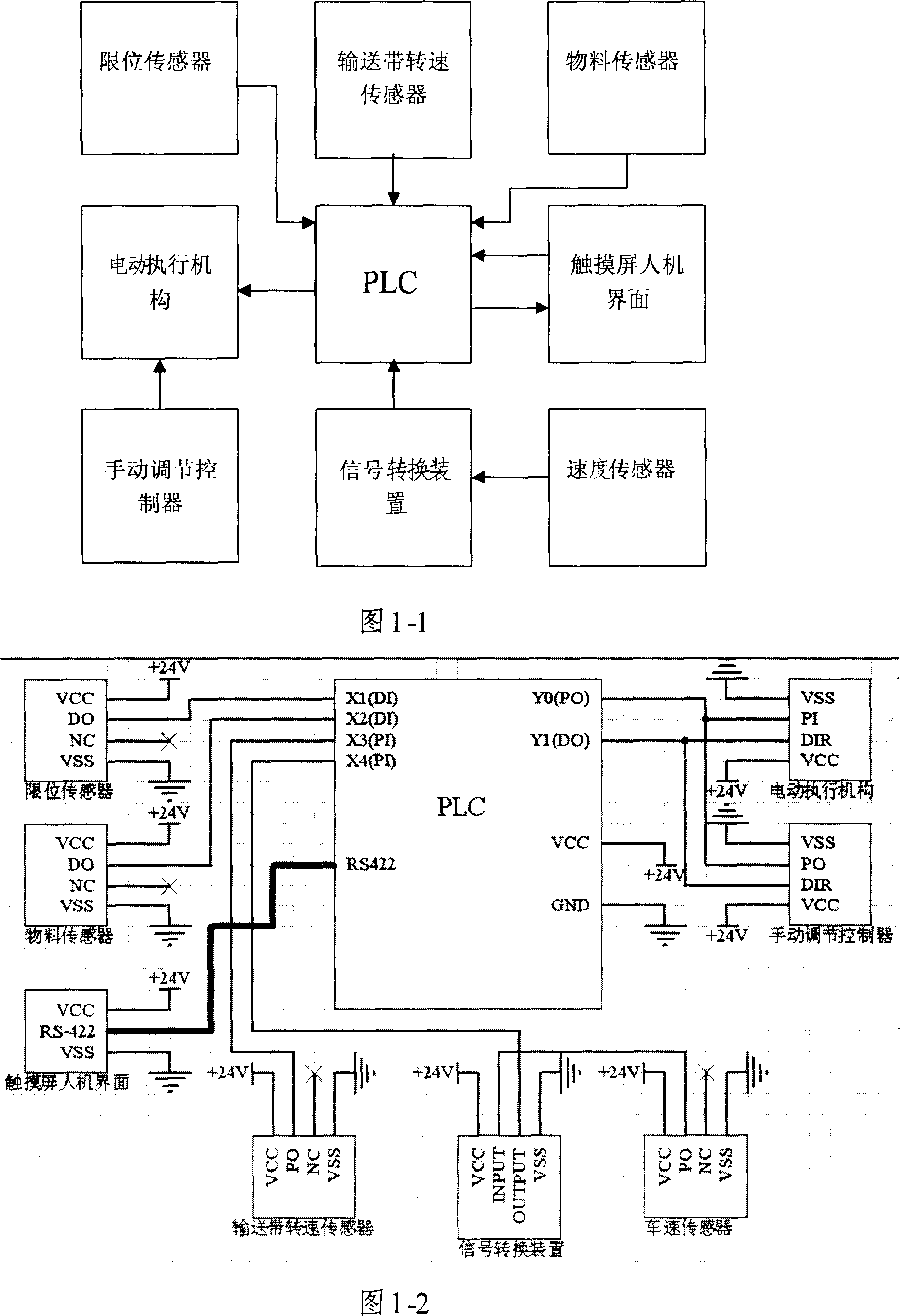

[0034] The invention applies the widely used PLC control system in industrial process control to engineering vehicles to realize reliable control in harsh environments. As shown in Figure 1, the architecture of the whole system is based on the PLC. The sensor collects various control parameters and outputs them to the PLC. The touch screen accepts the control parameters input by the staff and sends them to the PLC and displays the working status of the system to the staff. Specifically include:

[0035] —The central controller adopts a small programmable logic controller (PLC), which stores specific control programs including control algorithms. Its system connection mode and work flow are as follows: the switching input terminals of the PLC are respectively connected to the sensor outputs of each control parameter; After obtaining the various parameters req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com