Charred coal porosity measuring equipment and measuring method thereof

A technique for measuring devices and methods, applied in the fields of measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc., and can solve problems such as theoretical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Explain the technical solution in conjunction with the accompanying drawings

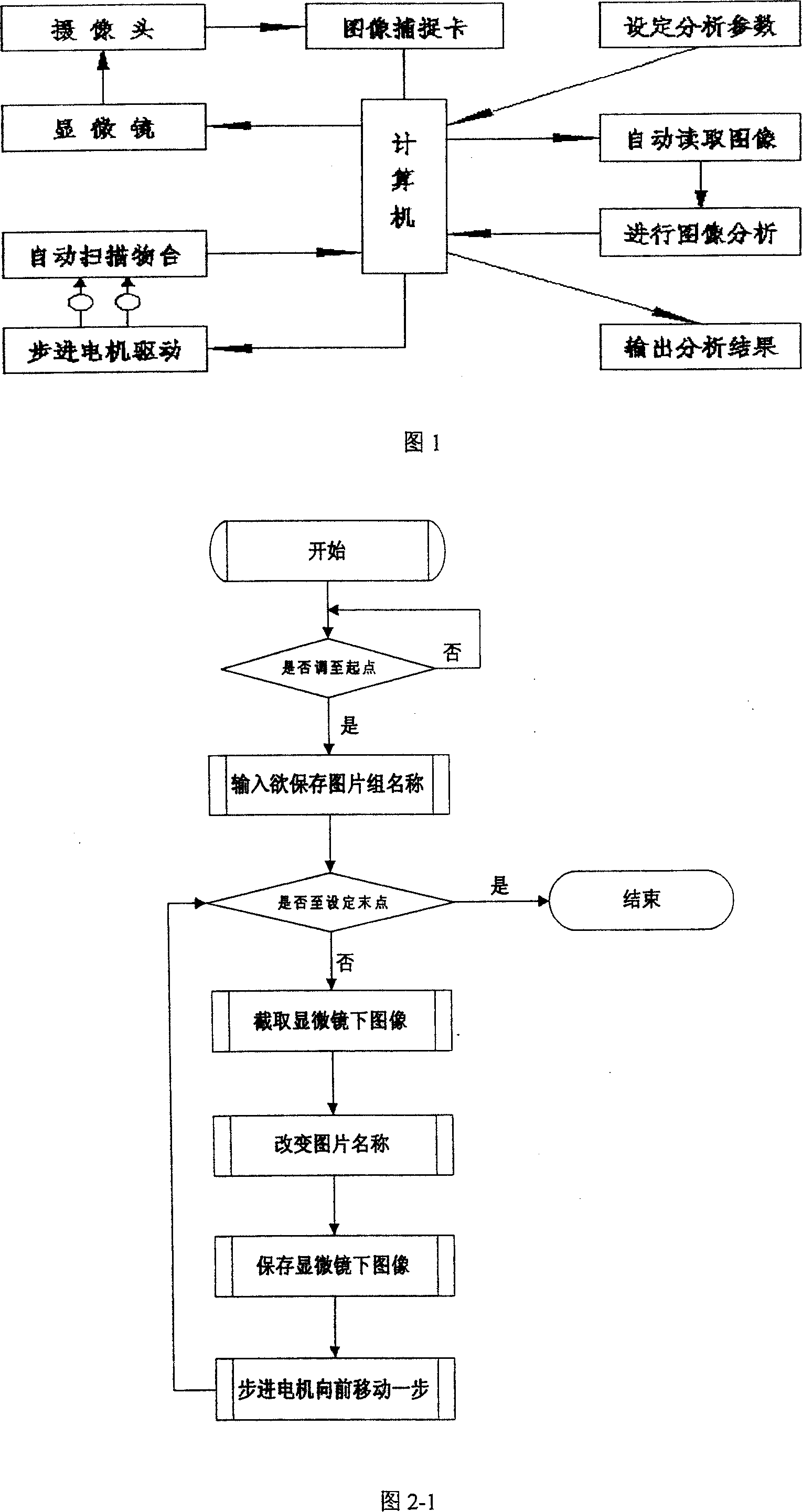

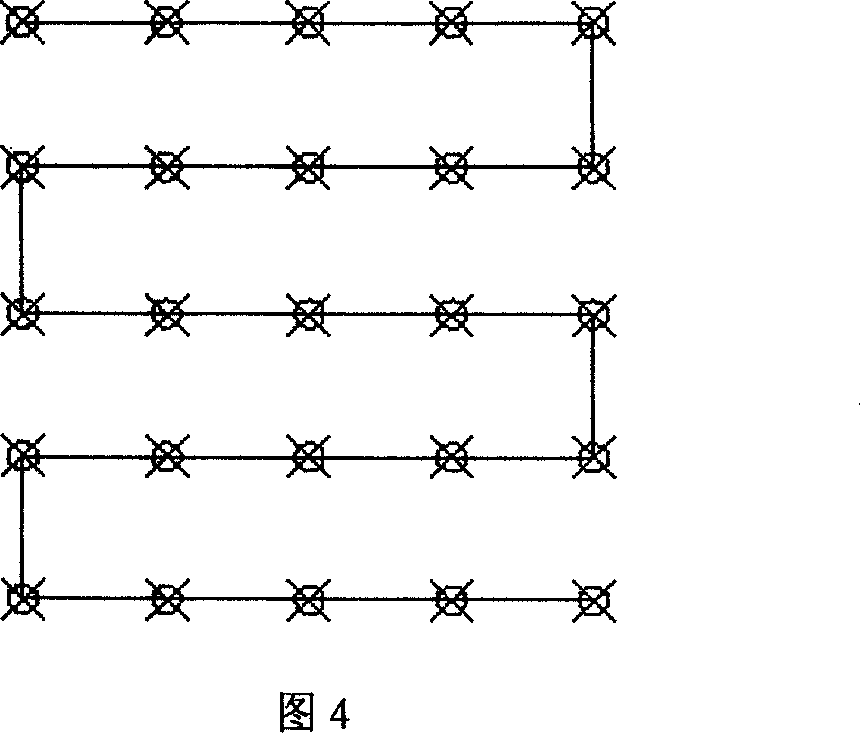

[0050] Referring to Fig. 1, Fig. 1 shows a computer-centered control system, an image acquisition system and an image analysis system forming a scanning object stage. The control system of the scanning object stage is to control the movement of the stepping motor of the scanning object stage through computer programming, so that it can automatically step and change direction during the scanning process to scan a complete film; the image acquisition system realizes the image under the microscope through the camera and image capture card. Save; the image analysis system is controlled by a program to continuously analyze multiple images.

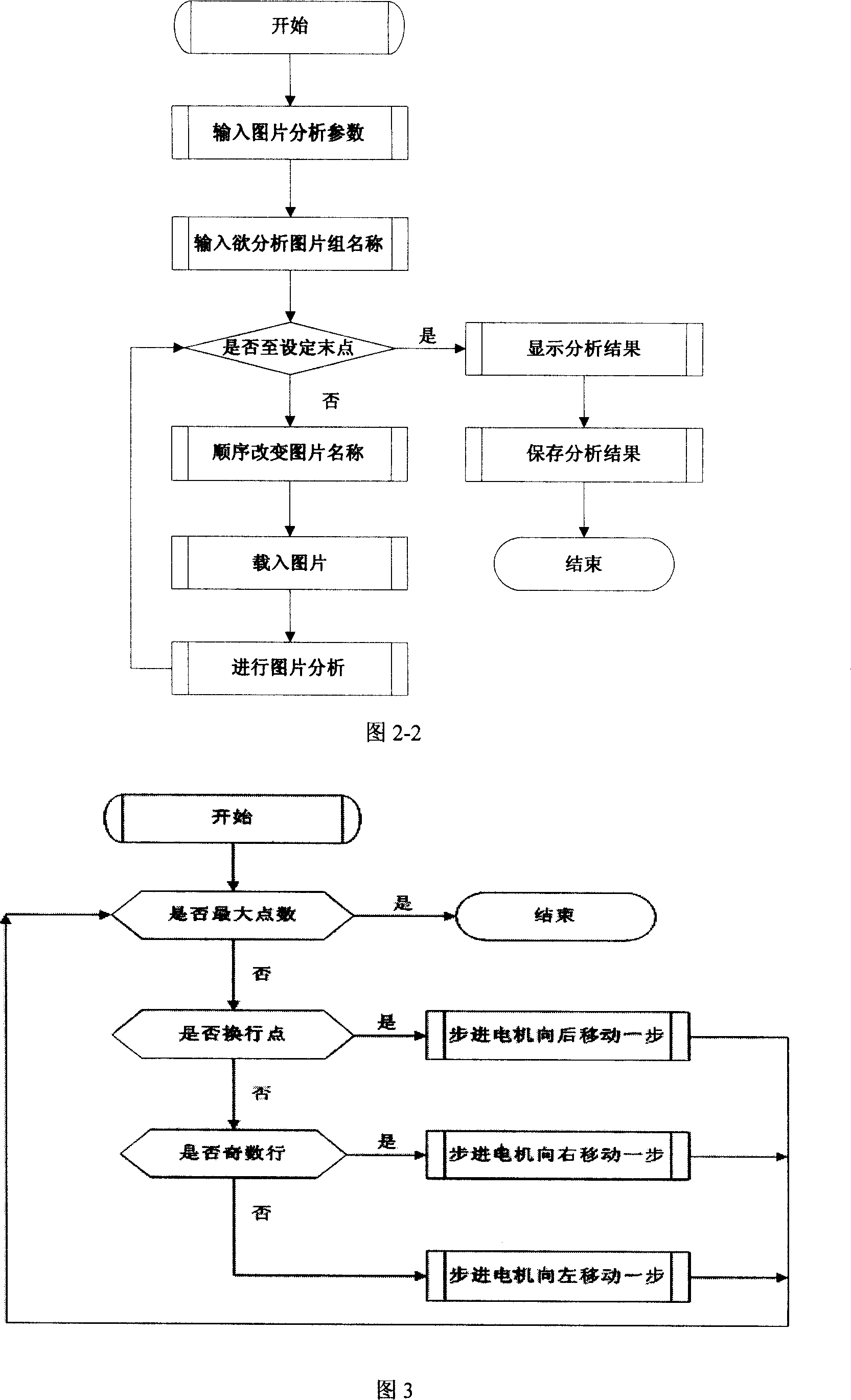

[0051] Refer to the picture acquisition module in Figure 2-1, adjust the sample to the starting point by setting the limit value, input the name of the picture group to be saved, the program will automatically realize, intercept the picture, change the picture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com