Energy-saving type mine main ventilator diffuser

A diffuser, energy-saving technology, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of large loss of kinetic energy at the outlet, increase the structural resistance of the diffuser, and increase the energy consumption of the main ventilator, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

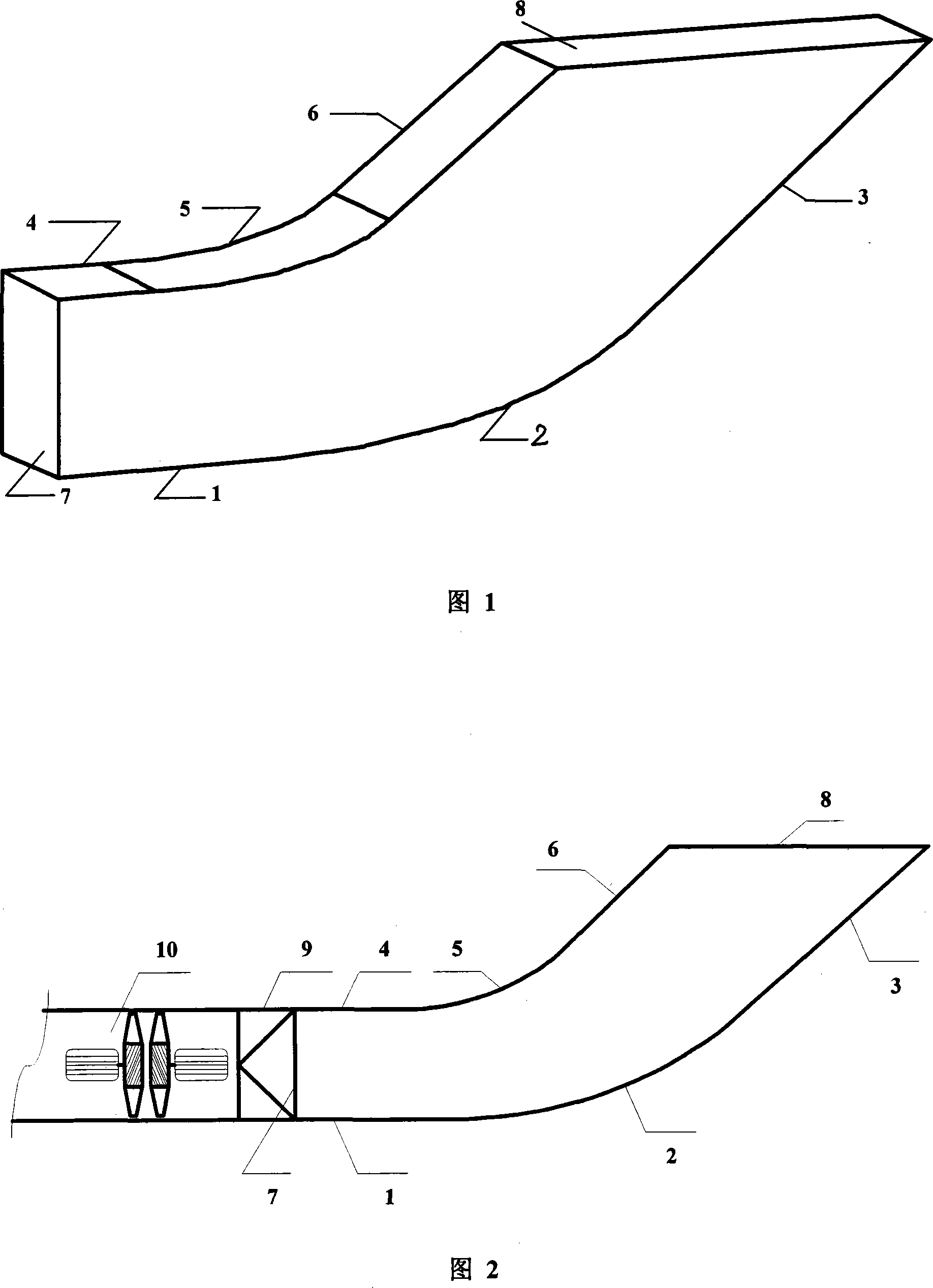

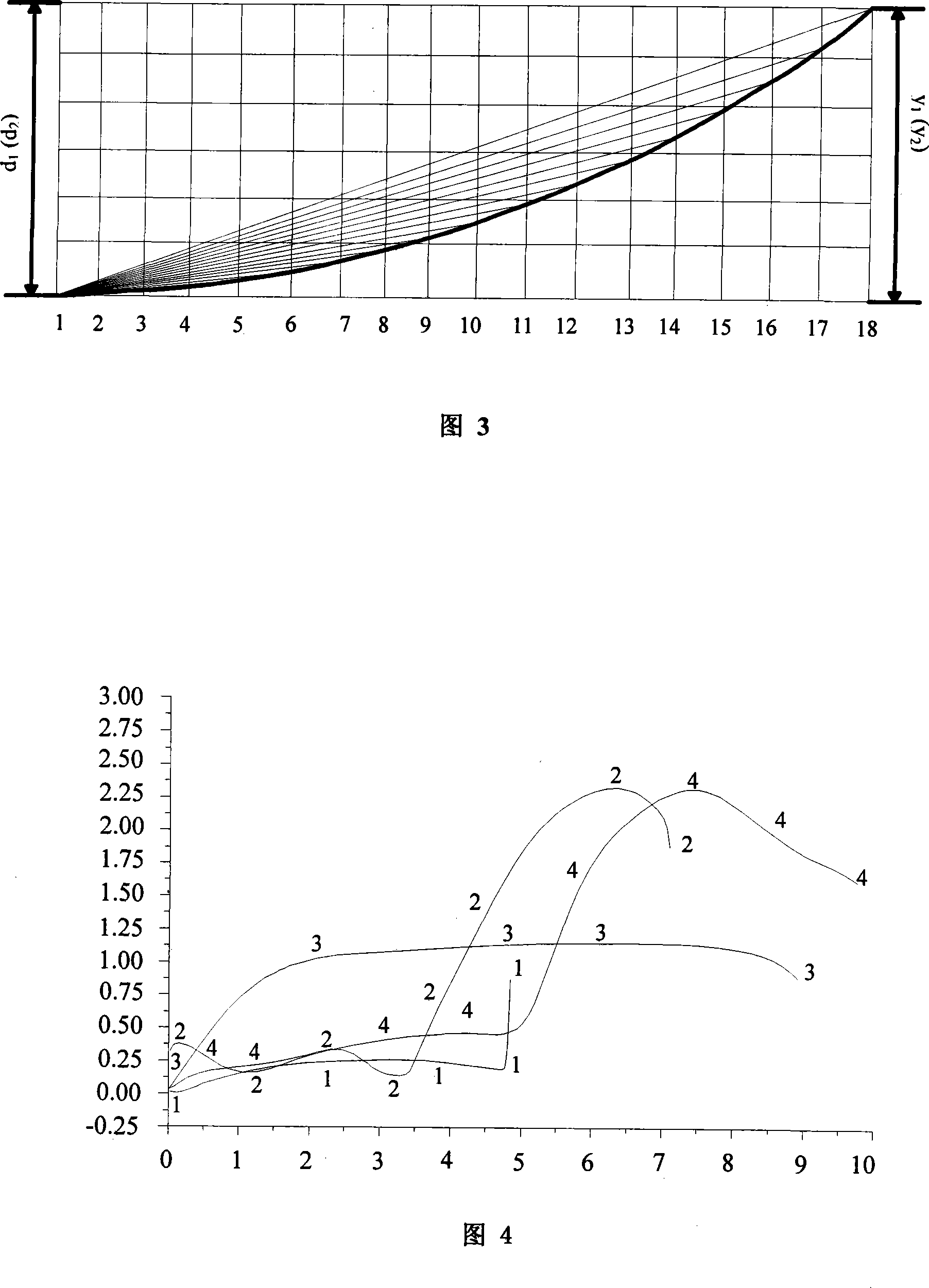

[0022] Referring to Fig. 1, the diffuser of the present invention is a sleeve-shaped member with a square cross section, its front and rear sides are planes, its upper surface is composed of inner contour lead plane, streamlined inner contour curved surface and inner contour extension line plane, its lower The surface is composed of outer contour lead plane, streamlined outer contour curved surface and outer contour extension plane; its left end is the inlet section 7, which is perpendicular to the horizontal plane; its right end is the outlet section 8, which is parallel to the horizontal plane; the area of the outlet section is larger than that of the inlet section area. It can be seen from the figure that the outer contour lead line 1, the streamlined outer contour line 2 and the outer contour extension line 3 respectively constitute the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com