Outer heating process multiple corrugated magnesium-smelting reduction jug

A technology of reduction tank and corrugated shape, which is applied in the field of magnesium smelting, key equipment required in metal magnesium smelting, metallurgy, multi-corrugated magnesium smelting reduction tank by external heat method, and can solve the problems of short life, increased energy consumption, variable Flat shape and other problems, to achieve good heat absorption effect, strengthen its own strength, and increase the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

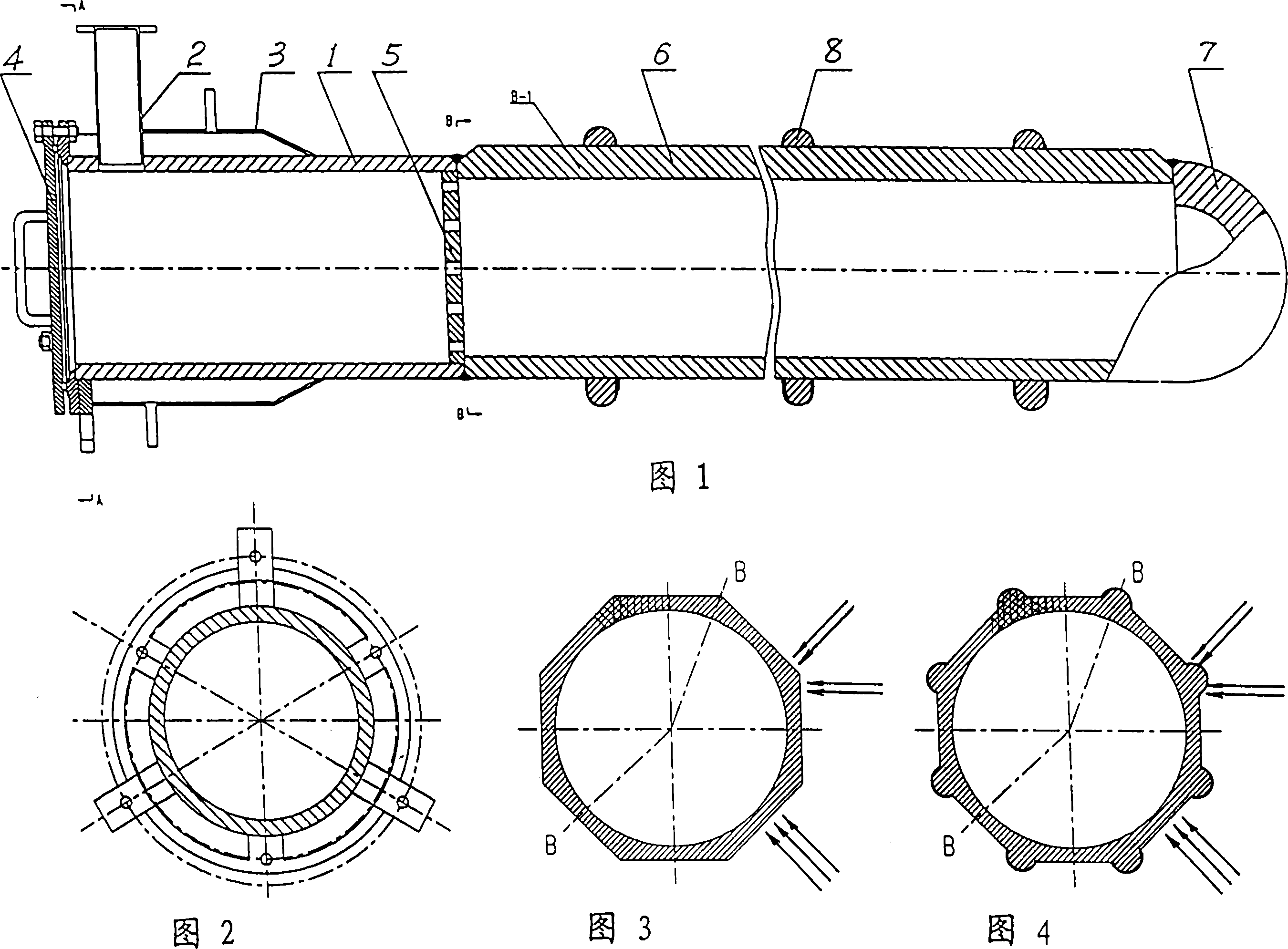

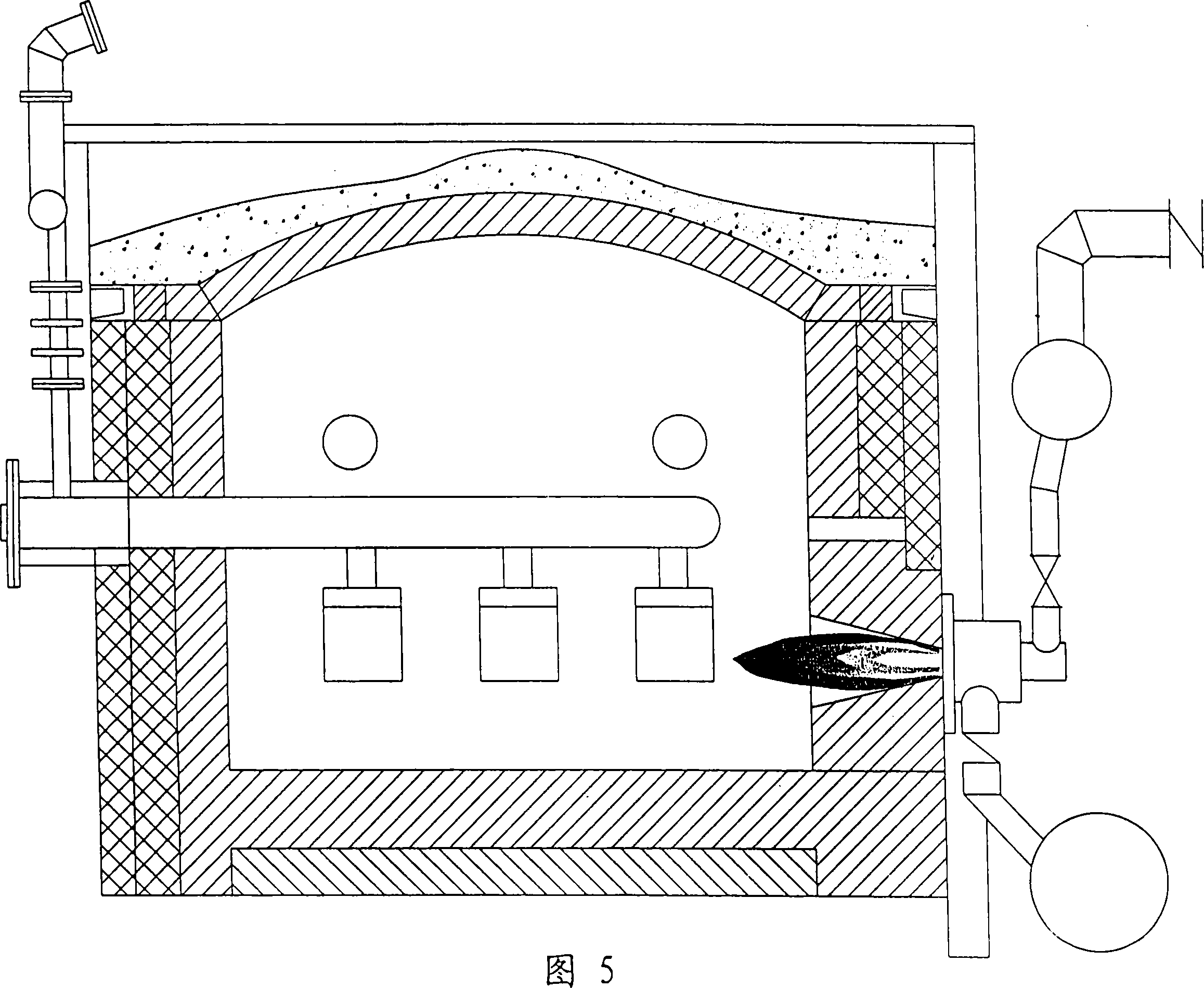

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0039]A multi-corrugated magnesium smelting reduction tank by external heat method, including cylinder 1, vacuum interface 2, water cooling 3, end cover 4, heat insulation board 5, and is also provided with corrugated cylinder 6, cylinder head 7, reinforcement A corrugated tank made of hoops 8;

[0040] The multi-corrugated magnesium smelting reduction tank of the external heat method, the cylinder 1 and the vacuum interface 2, the cylinder 1 and the water cooling 3, and the vacuum interface 2 and the water cooling 3 are all welded and connected, and the cylinder 1 and the end cover 4 are connected by welding. The way of the flange is fastened and connected by fasteners. The cylinder 1 and the corrugated cylinder 6, the corrugated cylinder 6 and the cylinder head 7 are all welded and connected, and the corrugated cylinder 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com