Process for producing polyketone

A manufacturing method and polyketone technology, applied in the field of polyketone manufacturing, can solve the problems of inability to obtain polymers and high-performance materials, etc., and achieve the effect of improving catalyst activity and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

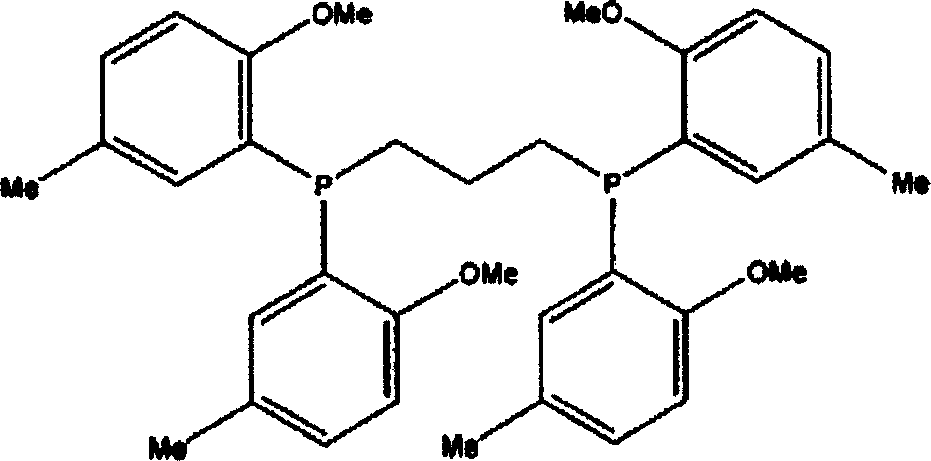

[0050] 0.0129 g of palladium acetate, 0.0366 g of 1,3-bis[bis(2-methoxy-5-methylphenyl)phosphino]propane (BIBMAPP) were dissolved in a mixed solvent containing 2249 ml of acetic acid and 417 ml of water. This solution was charged into a stainless steel autoclave which was replaced with nitrogen after removing the air by vacuum. The autoclave was closed, then the contents were stirred at 700 rpm while heating. When the inner temperature reached 90° C., a mixed gas of carbon monoxide and ethylene in a molar ratio of 1:2 was added until the inner pressure of the autoclave was 65 bar. Keep the conditions of internal temperature 90°C and internal pressure 65 bar, and keep stirring for 1 hour. After cooling, the gas in the autoclave was removed, and the contents were taken out. The reaction solution was filtered, washed several times with methanol, and then dried under reduced pressure at room temperature to 80° C. to obtain 73 g of a polymer.

[0051] Depend on 13 As a result o...

Embodiment 2

[0054] 0.0129 g of palladium acetate, 0.0366 g of 1,3-bis[bis(2-methoxy-5-methylphenyl)phosphino]propane (BIBMAPP) were dissolved in a mixed solvent containing 2249 ml of acetic acid and 417 ml of water. This solution was charged into a stainless steel autoclave which was replaced with nitrogen after removing the air by vacuum. The autoclave was closed, then the contents were stirred at 700 rpm while heating. When the inner temperature reached 90° C., a mixed gas of carbon monoxide and ethylene in a molar ratio of 1:2 was added until the inner pressure of the autoclave was 70 bar. Keep the conditions of internal temperature 90°C and internal pressure 70 bar, and keep stirring for 15 hours. After cooling, the gas in the autoclave was removed, and the contents were taken out. The reaction solution was filtered, washed several times with methanol, and then dried under reduced pressure at room temperature to 80°C to obtain 890.3 g of a polymer.

[0055] Depend on 13 As a resul...

Embodiment 3

[0058] 0.0236 g of palladium acetate, 0.0674 g of 1,3-bis[bis(2-methoxy-5-methylphenyl)phosphino]propane (BIBMAPP) were dissolved in a mixed solvent containing 1350 ml of acetic acid and 250 ml of water. This solution was charged into a stainless steel autoclave which was replaced with nitrogen after removing the air by vacuum. The autoclave was closed, then the contents were stirred at 700 rpm while heating. When the inner temperature reached 90° C., a mixed gas of carbon monoxide and ethylene in a molar ratio of 1:2 was added until the inner pressure of the autoclave was 45 bar. Keep the conditions of internal temperature 90° C. and internal pressure 45 bar, and keep stirring for 1 hour. After cooling, the gas in the autoclave was removed, and the contents were taken out. The reaction solution was filtered, washed several times with methanol, and then dried under reduced pressure at room temperature to 80°C to obtain 183.9 g of a polymer.

[0059] Depend on 13 As a resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com