Rim for a bicycle spoked wheel, process suitable for manufacturing it, and relative spoked wheel

A technology for bicycles and spoked wheels, applied to spoked wheels, wheels, rims, etc., can solve the problems of increased fatigue fracture, increased stress of wheel elements, loss of stiffness, high tension force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

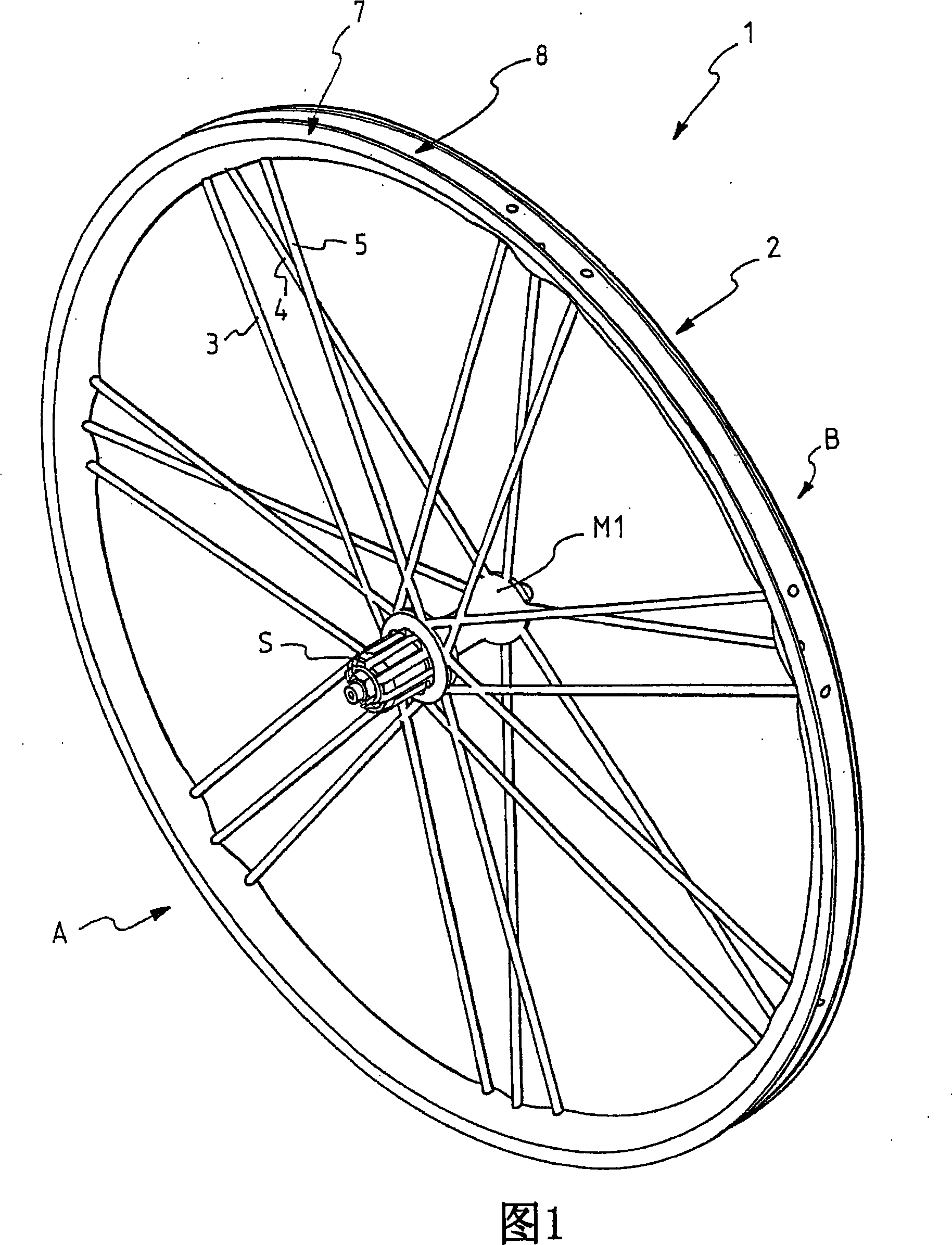

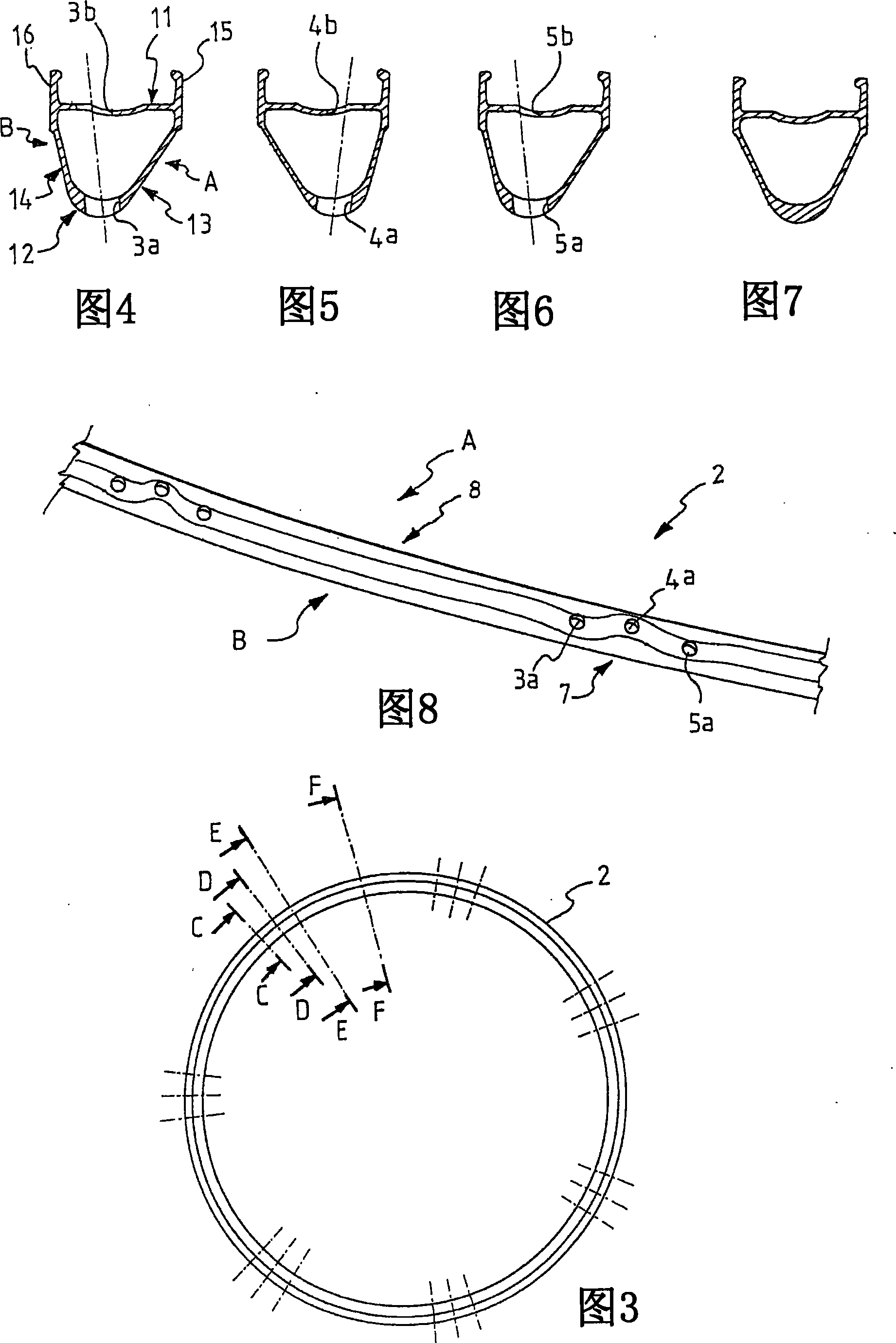

[0102] Figure 1 shows a wheel 1 with a rim 2 according to a first embodiment of the invention.

[0103] The wheel 1 is a rear wheel with seven triplets, each said triplet comprising three spokes 3, 4, 5 in the area of seven spoke connections between the hub M1 and said rim 2 7 between tension. Between adjacent spoke connection areas 7 , the rim 2 has seven sub-spoke areas 8 .

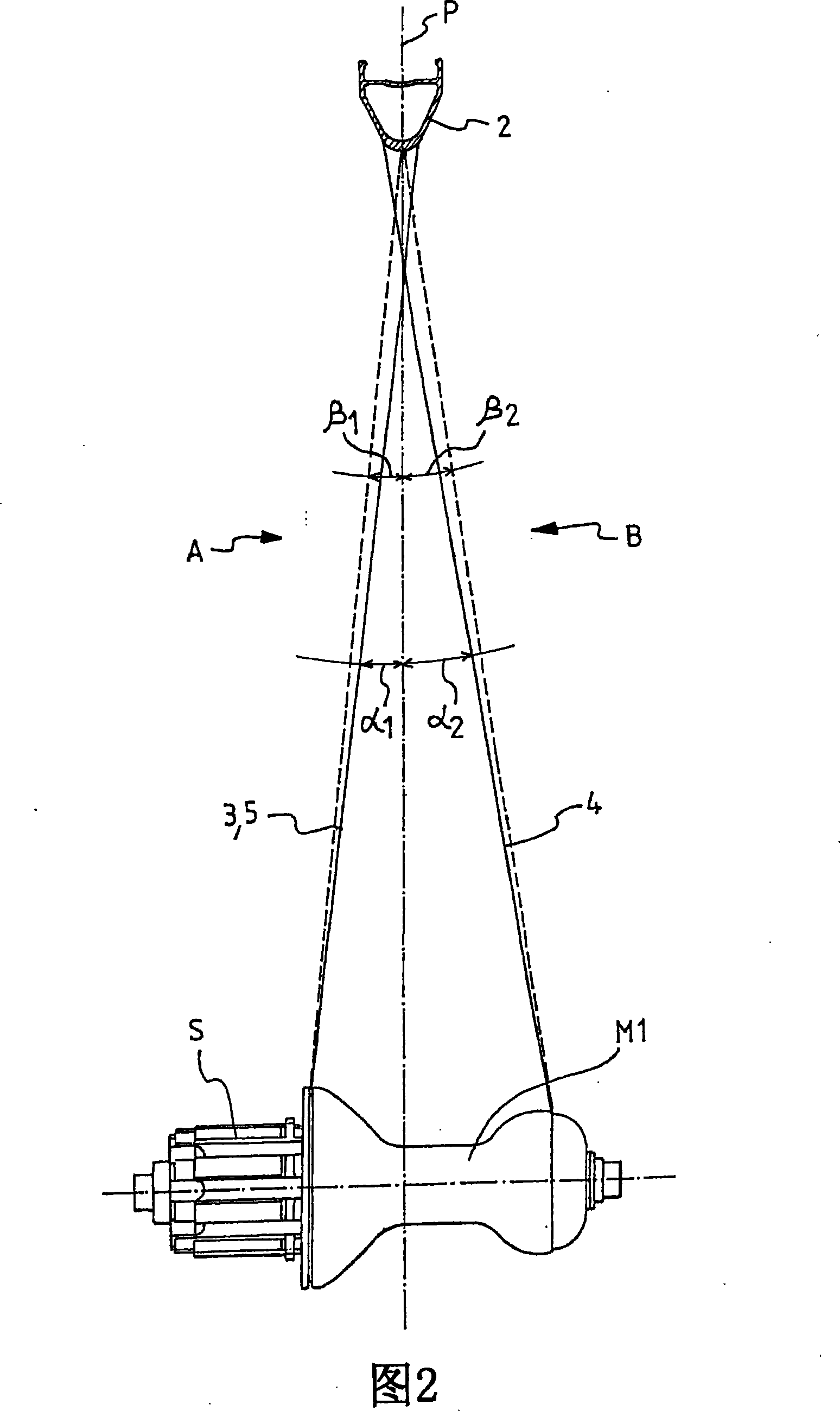

[0104] Two sides A, B are defined in the wheel 1 and in the corresponding rim 2 , a first side fixed to the hub M1 on one side of the pinion support S and a second side on the opposite side.

[0105] Said side spokes 3, 5 of each triplet extend tangentially from said hub M1 on a first side A, while central spokes 4 of each triplet extend from said hub M1 on said second side B Extend radially.

[0106] Thus, there are twice as many spokes 3 , 5 (fourteen) on the first side A as there are spokes 4 on the second side B (seven).

[0107] As can be seen from the cross-sectional view of FIG. 2 , the inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com