Disk chipper

A disc chipper and cutter head technology, which is used in the manufacture of veneer chips, wood processing appliances, manufacturing tools, etc., can solve the problems of inability to adjust the distance and narrow cutting range, and achieve a wide cutting range and many cutting specifications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

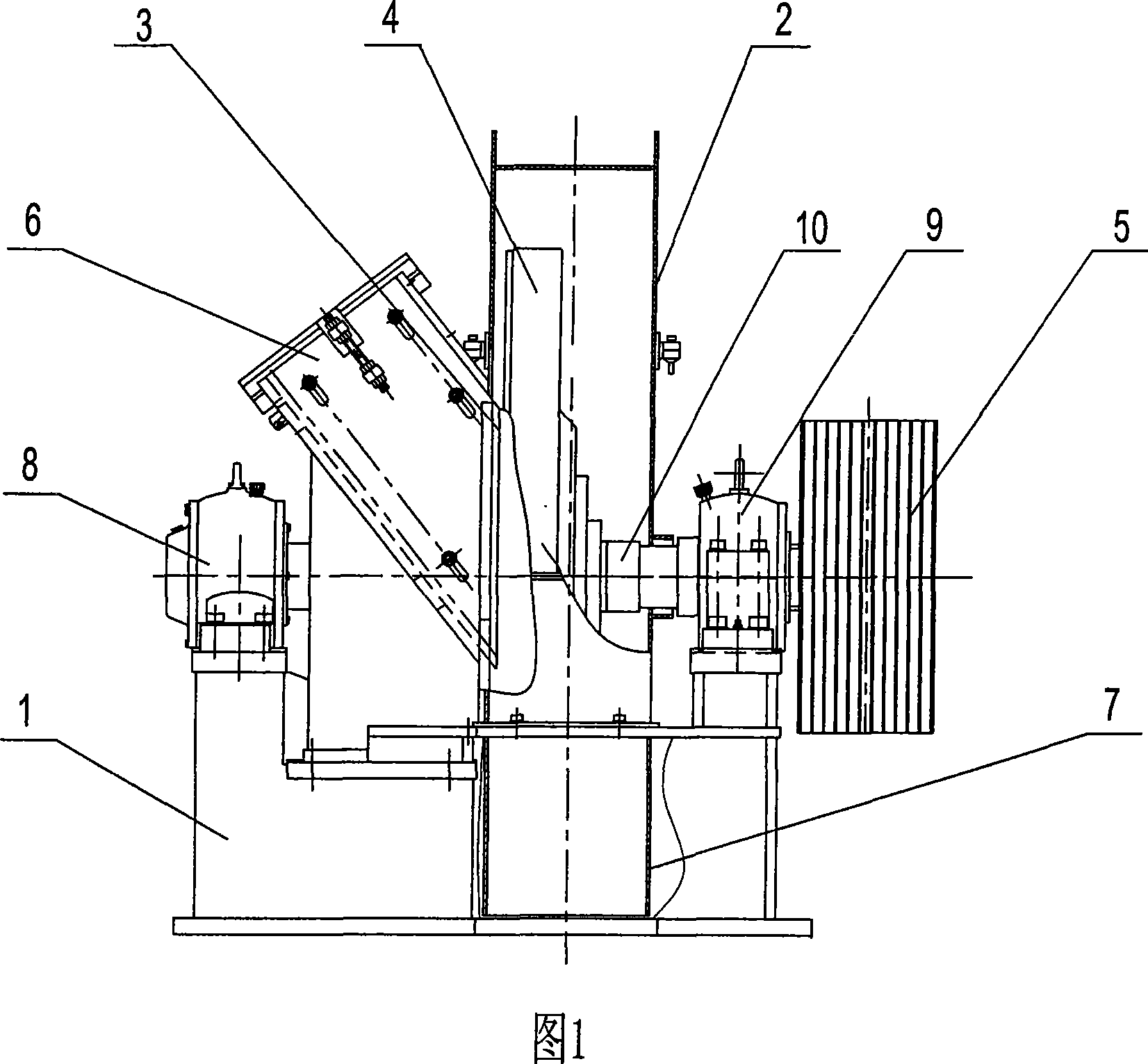

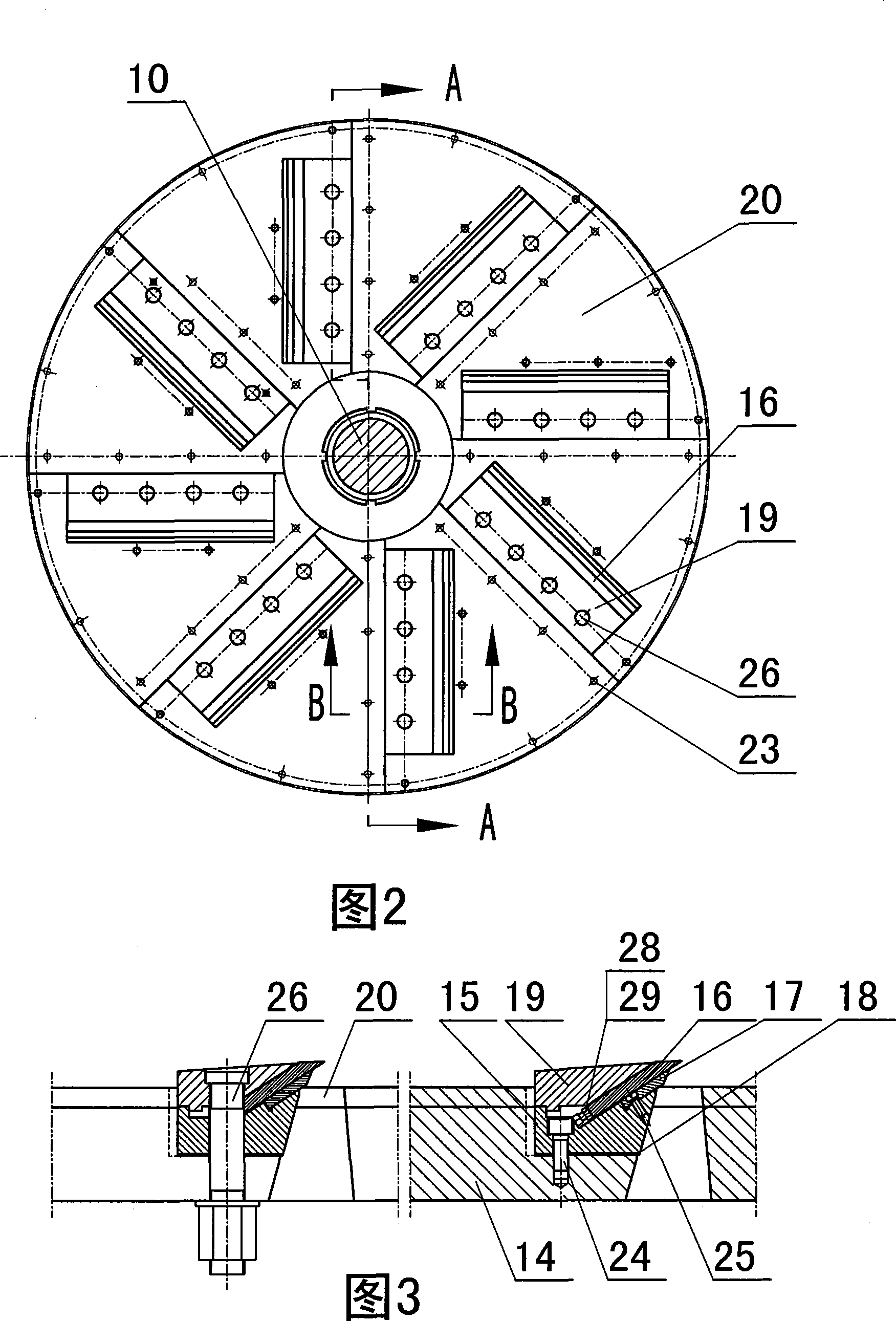

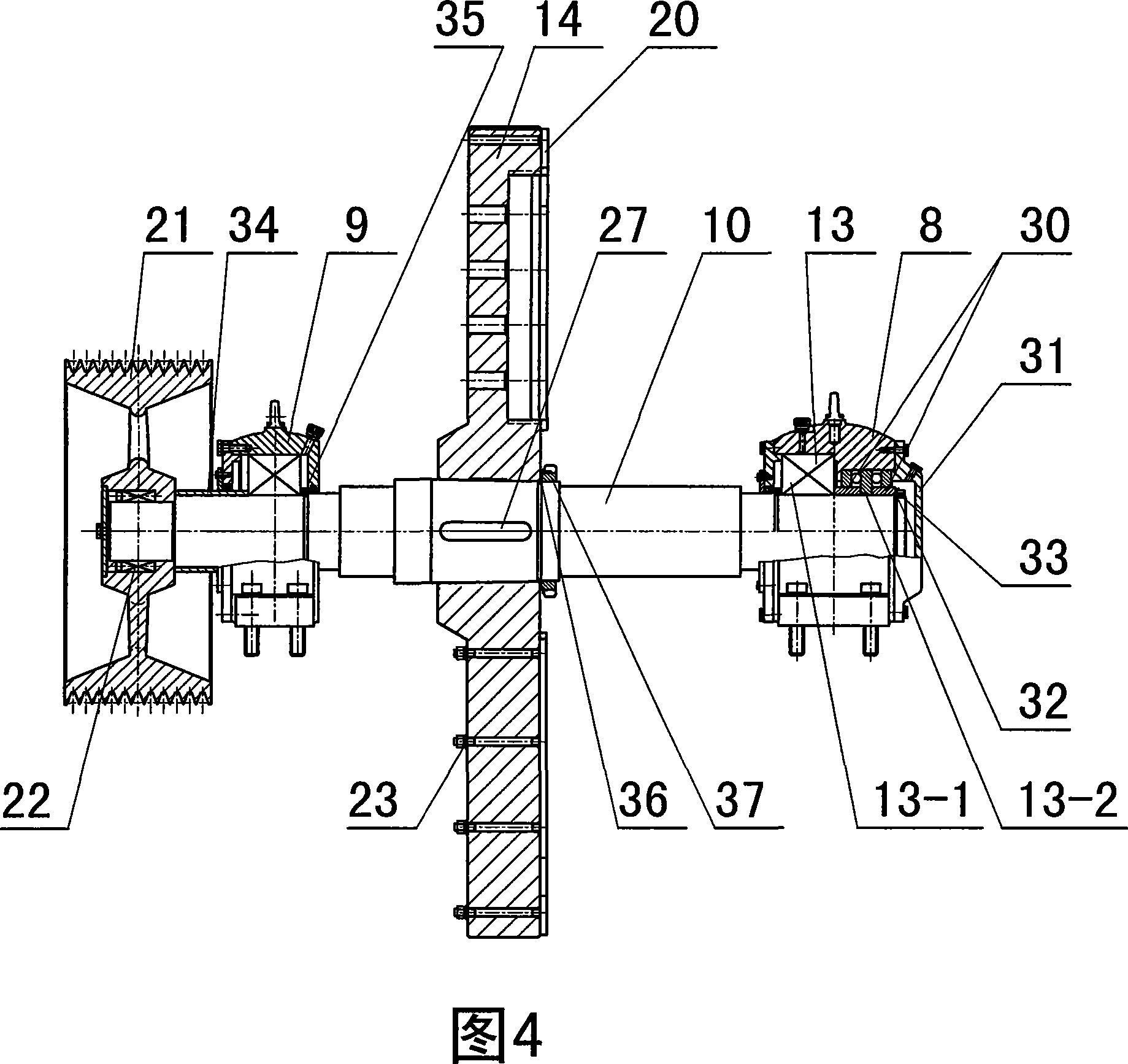

[0018] As shown in Figures 1 to 5, a disc chipper includes a machine base 1, a cutter head cover 2, a feeding device 3, a cutter head device 4, and a transmission device 5, and the cutter head cover 2 is fixed on the machine. On the seat 1, a feeding device 3 is fixed on the side of the cutter head cover 2, and a feeding port 6 is opened on the feeding device 3. The bottom knife 11, the side knife 12 on the left side and the side knife 12 on the right side are installed on the feeding device 3. The side knife 12, the lower part of the cutterhead cover 2 has a discharge port 7, and the cutterhead device 4 includes a main shaft 10, a cutterhead 14, 8 flying knives 16, 8 back knives 17, 8 pressure knife blocks 19, 8 Wear-resistant plate 20, described cutter head 14 disc surfaces are plane, wear-resistant plate 20 is fan-shaped, and 8 wear-resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com