Manufacturing method for extruding noodle

A production method and noodle technology, which can be used in dough processing, food preparation, dough extruding machines, etc., can solve the problems of poor noodle texture, lower quality of noodle products, and easy noodle breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

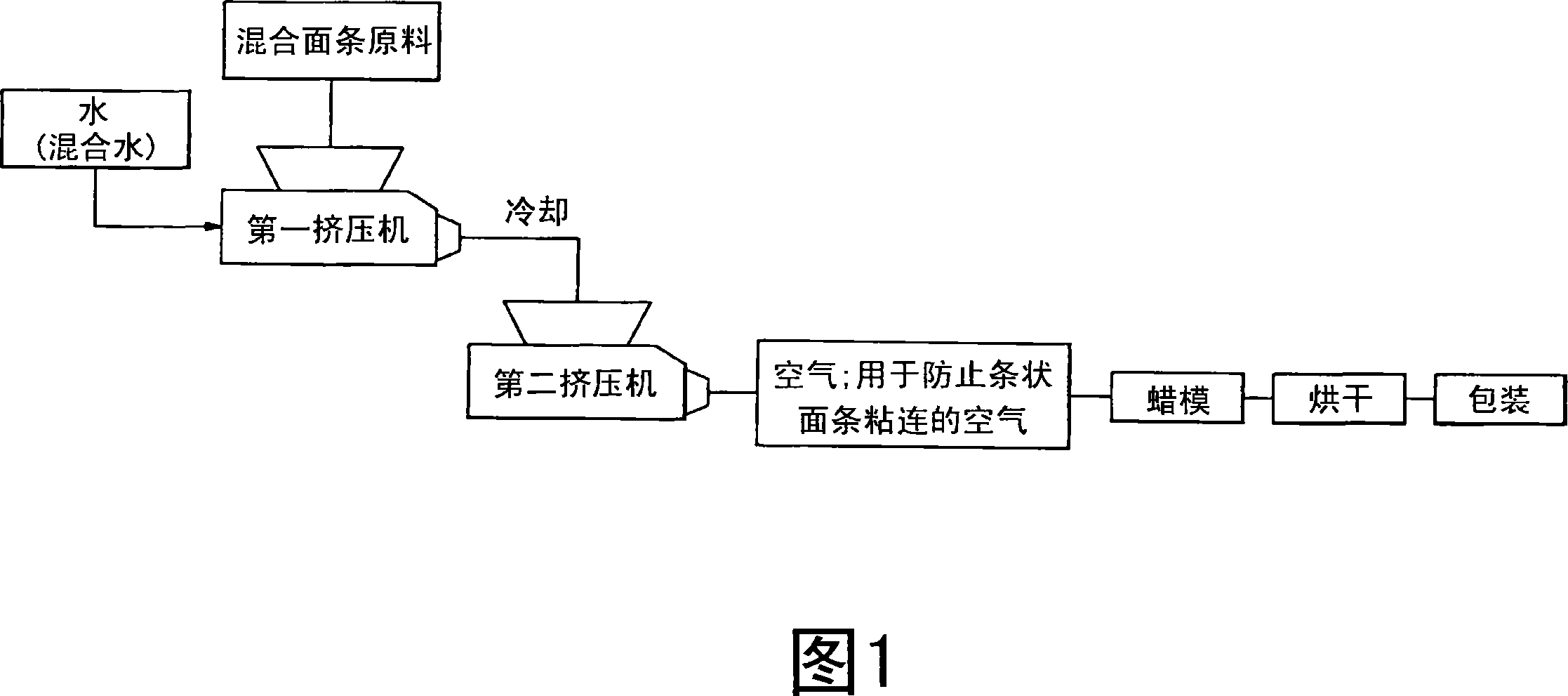

Method used

Image

Examples

example

[0046] 60% by weight of wheat flour and 40% by weight of potato starch and buckwheat flour are put into the first extruder. Here, the amount of mixing water added to the noodle mix was 30% by weight of the noodle mix. 1% refined salt by weight is dissolved in the mixing water in advance.

[0047] When the noodle mixed raw material and mixed water are put into the first extruder at the same time, the temperature of the drum is controlled so that the mixed raw material is kneaded into a dough, and at the same time the raw dough can be gelatinized. Each time, the gelled dough was cooled to a temperature of 30°C, and then a prescribed amount of the gelled dough was put into the second extruder, and extruded into strip-shaped noodles. Here, the die hole diameter of the extruder was 0.7 mm.

[0048] The strip-shaped noodles extruded by the second extruder were cut to a length of 40 cm, and a prescribed amount of the cut strip-shaped noodles was put into a wax mold. The noodles in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com