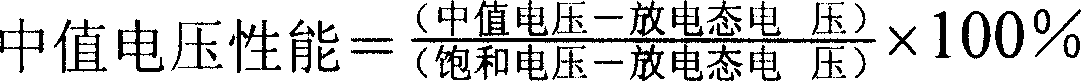

Method for appraising sphere nickel median voltage performance

A ball nickel and voltage technology, applied in the field of evaluating the median voltage performance of ball nickel, can solve problems such as long cycle, reduce production costs, reduce testing and inspection costs, and save manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This example is used to illustrate the method for evaluating the median voltage performance of spherical nickel provided by the present invention.

[0020] Instrument: D / MAX2200PC X-ray powder diffractometer produced by Rigaku Corporation;

[0021] Instrument configuration and test conditions: Copper X-ray source, wavelength λ=1.54056 angstroms, Cu / Kα1, Cu target power is 40 kV, 20 mA; graphite monochromator is used; goniometer scan rate is 4 degrees / minutes, the scanning range is 2θ=15°-65°, the scanning method is θ / 2θ linkage scanning; the scanning step is 0.02 degrees / step; the optical path divergence slit is 1°, the anti-scattering slit is 10mm, Change the slit to automatic adjustment of the instrument, and the receiving slit is 0.3mm;

[0022] Instrument data processing software: MDI-JADE (5.0);

[0023] Spherical nickel sample: cadmium-added spherical nickel sample (D03 cadmium-added type, Jiangmen Changyou Industrial Co., Ltd.), numbered A;

[0024] Specific s...

Embodiment 2-6

[0030] This group of examples 2-6 is used to illustrate the method for evaluating the median voltage performance of spherical nickel provided by the present invention.

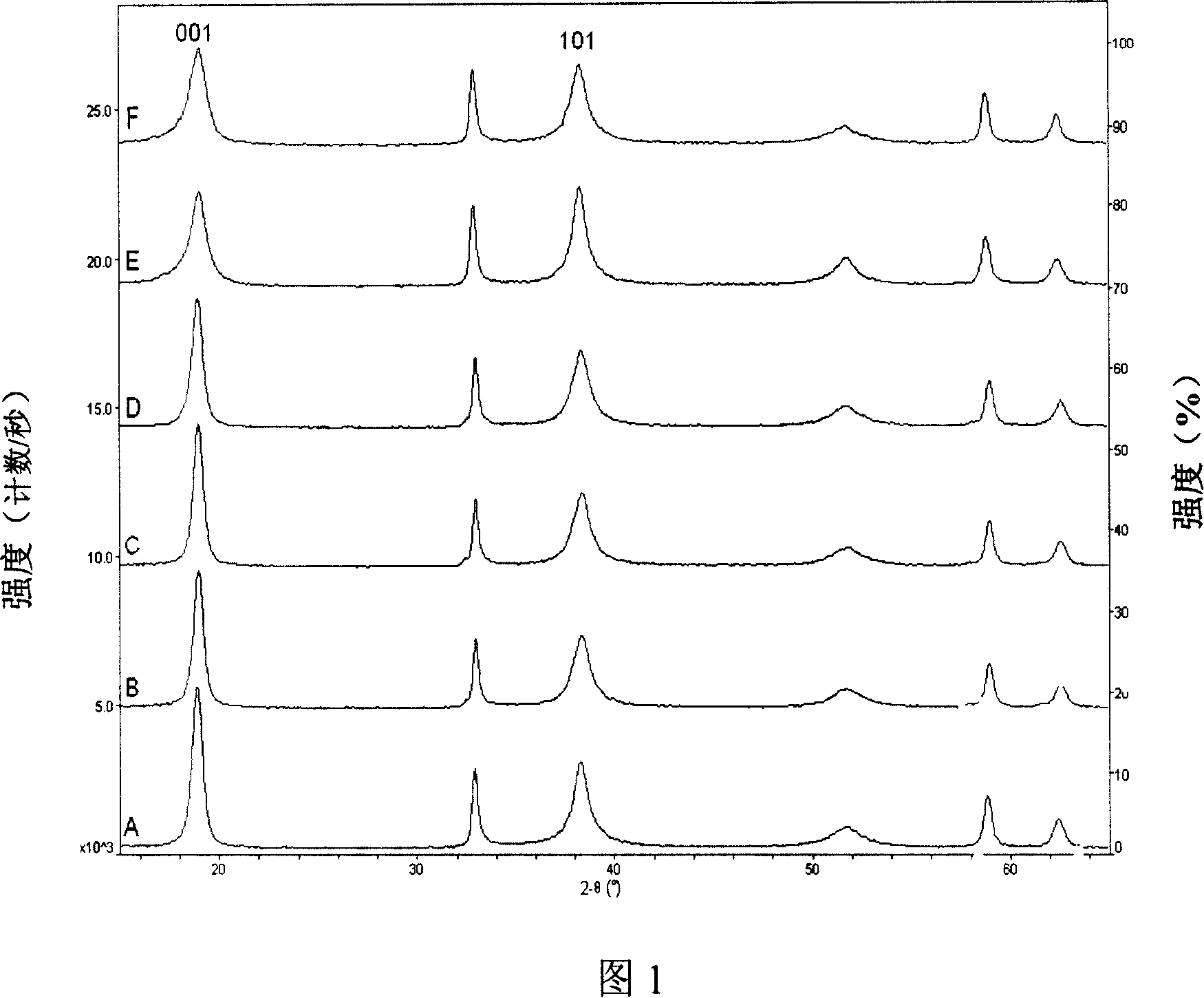

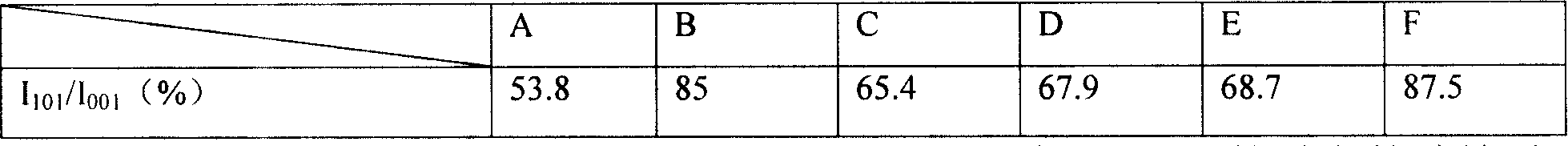

[0031]Add cadmium spherical nickel sample B (SY-1 adds cadmium type, Xiamen Fangyuan Chemical Industry Co., Ltd.), C (D03 adds cadmium type, Jiangmen Changyou Industrial Co., Ltd.), D respectively according to the test method described in Example 1. (D03 cadmium-added type, Jiangmen Changyou Industrial Co., Ltd.), E (D03 cadmium-added type, Jiangmen Changyou Industrial Co., Ltd.) and F (SY-2 cadmium-added type, Xiamen Fangyuan Chemical Industry Co., Ltd.) XRD diffraction test , to obtain the I of the sample 101 / I 001 , and evaluate the electrochemical performance of the spherical nickel sample according to the method described in Example 1. Obtain the diffractogram of sample as shown in B, C, D, E, F in Fig. 1, measurement result is as shown in B, C, D, E, F in table 1, wherein, sample A, C, D, E Both are ...

Embodiment 7-12

[0036] This group of examples is used to prepare batteries.

[0037] Preparation of positive electrode sheet

[0038] Weigh 42.5 parts by weight of spherical nickel samples A, B, C, D, E, F and 10 parts by weight of conductive agent nickel powder, 3.5 parts by weight of improver CoO, and 1 part by weight of binder polytetrafluoroethylene , 20 parts by weight of water mixed and stirred evenly to prepare positive electrode slurry, respectively coated on the foamed nickel mesh with drainage fluid, dried and calendered at 150 ° C to grow 200 mm, 30 mm wide, and 0.75 mm thick positive electrode sheet Z1, Z2 , Z3, Z4, Z5, Z6, wherein the contents of the positive electrode active material in the positive electrode sheets Z1, Z2, Z3, Z4, Z5, Z6 are all 3.75 grams.

[0039] Preparation of negative electrode sheet

[0040] Weigh 40 parts by weight of CdO powder, 10 parts by weight of Cd powder, and 25 parts by weight of water, mix and stir evenly to prepare negative electrode slurry, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com