Enveloping method for coating silicon gel rubber with plastic film and finished product thereof

A plastic film, silicone gel technology, applied in rubber layered products, packaging/bundling items, chemical instruments and methods, etc., can solve the problems of glue overflow, unstable quality, time-consuming, etc., so as to reduce manufacturing costs and reduce overflow. The effect of glue risk and product quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

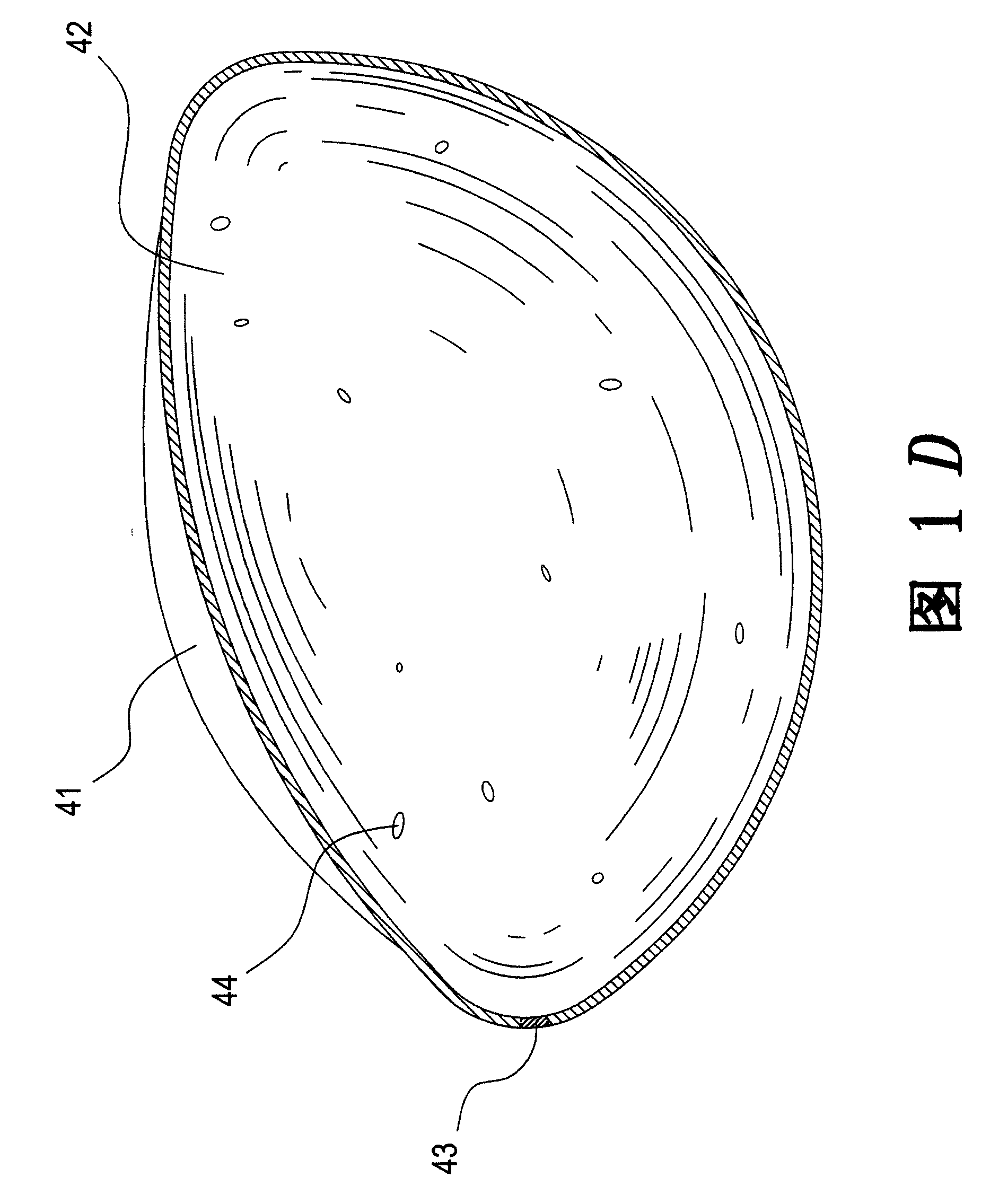

[0046] Please refer to Figures 2A, B, C, D and Figure 3, the process steps of the sealing method in which the silicone gel is coated with a plastic film provided by the present invention are:

[0047] Step 1: First, form the first and second plastic films 11, 12 by a film forming machine, each of the first and second plastic films 11, 12 has a contact surface 111, 121 connected to the silicone gel 2;

[0048] Step 2: Plasma treatment (PLASMA-CASING PROCESS) is performed on the contact surfaces 111, 121 connecting the first and second plastic films 11, 12 and the silicone gel 2 by a plasma processor to make the first and second plastic films 11 The wettability of the contact surfaces 111, 121 of, 12 is increased, resulting in the contact surfaces 111, 121 being tightly connected to the silicone gel 2 (as shown in Figure 2A); in addition, the first and second plastic films can also be contacted Electron beam treatment (ELECTRON BEAM) can also increase the wettability of the first and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com