A digital high voltage DC power

A high-voltage DC power supply, high-frequency and high-voltage technology, applied in high-efficiency power electronic conversion, conversion of AC power input to DC power output, and conversion of DC power input to DC power output, etc., can solve the problem of insufficient voltage levels and inflexible voltage regulation methods and other issues to achieve the effect of improving efficiency, speeding up dynamic response time, and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

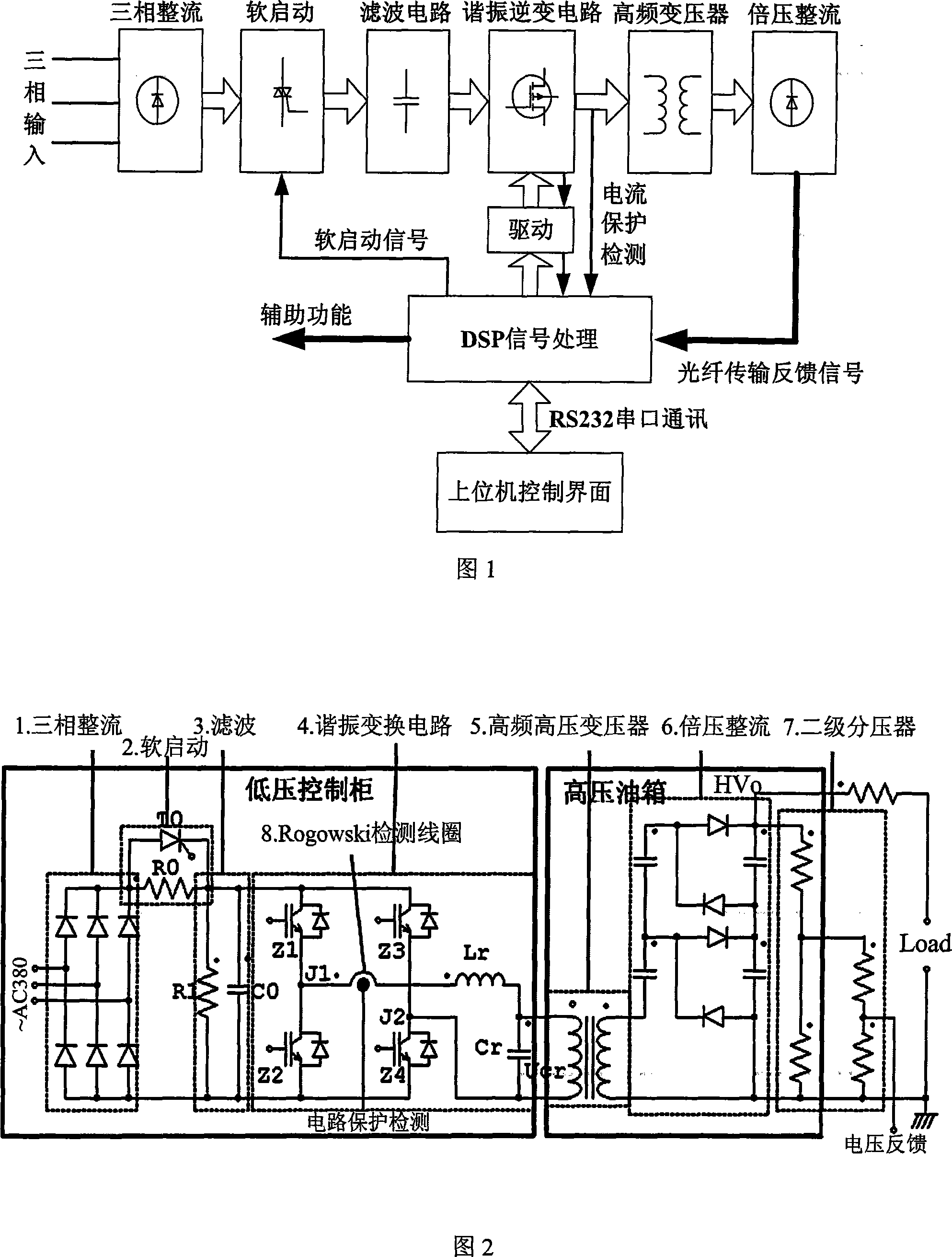

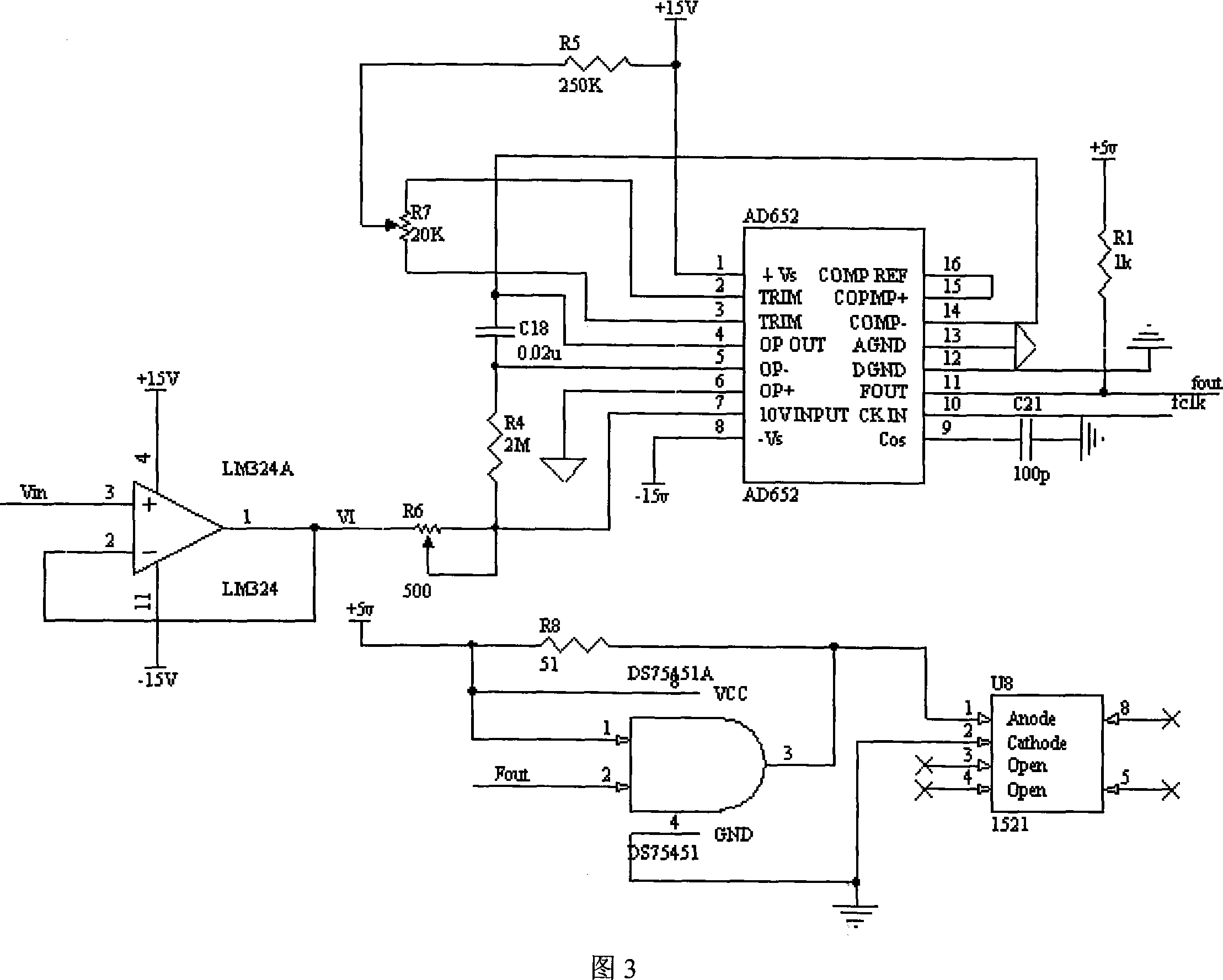

[0026] As shown in Figure 1, the present invention includes the following components: a power main circuit, a DSP-based digital control circuit and a PC-based host computer control program. The main power circuit includes a three-phase rectifier unit 1 , a soft start unit 2 , a filter unit 3 , a resonant inverter unit 4 , a high-frequency high-voltage transformer 5 , a voltage multiplier circuit 6 , and a secondary voltage divider 7 . The DSP-based digital control circuit includes an IPM drive signal interface circuit, a high-voltage feedback unit, a resonant overcurrent protection unit, a soft-start circuit, and a serial communication interface circuit. The three-phase rectifier unit 1, soft start unit 2, filter unit 3, resonant inverter unit 4, high-frequency high-voltage transformer 5, and voltage multiplier circuit 6 of the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com