Wafer transfer method and grinding device

A wafer and grinding technology, applied in transportation and packaging, grinding/polishing equipment, and machine tools suitable for grinding workpiece planes, etc., can solve problems such as uneconomical consumption, water waste, and difficulty in wafer peeling, and reduce water supply volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, a wafer transfer method which is the best mode for carrying out the present invention and a grinding device for carrying out the wafer transfer method will be described with reference to the drawings.

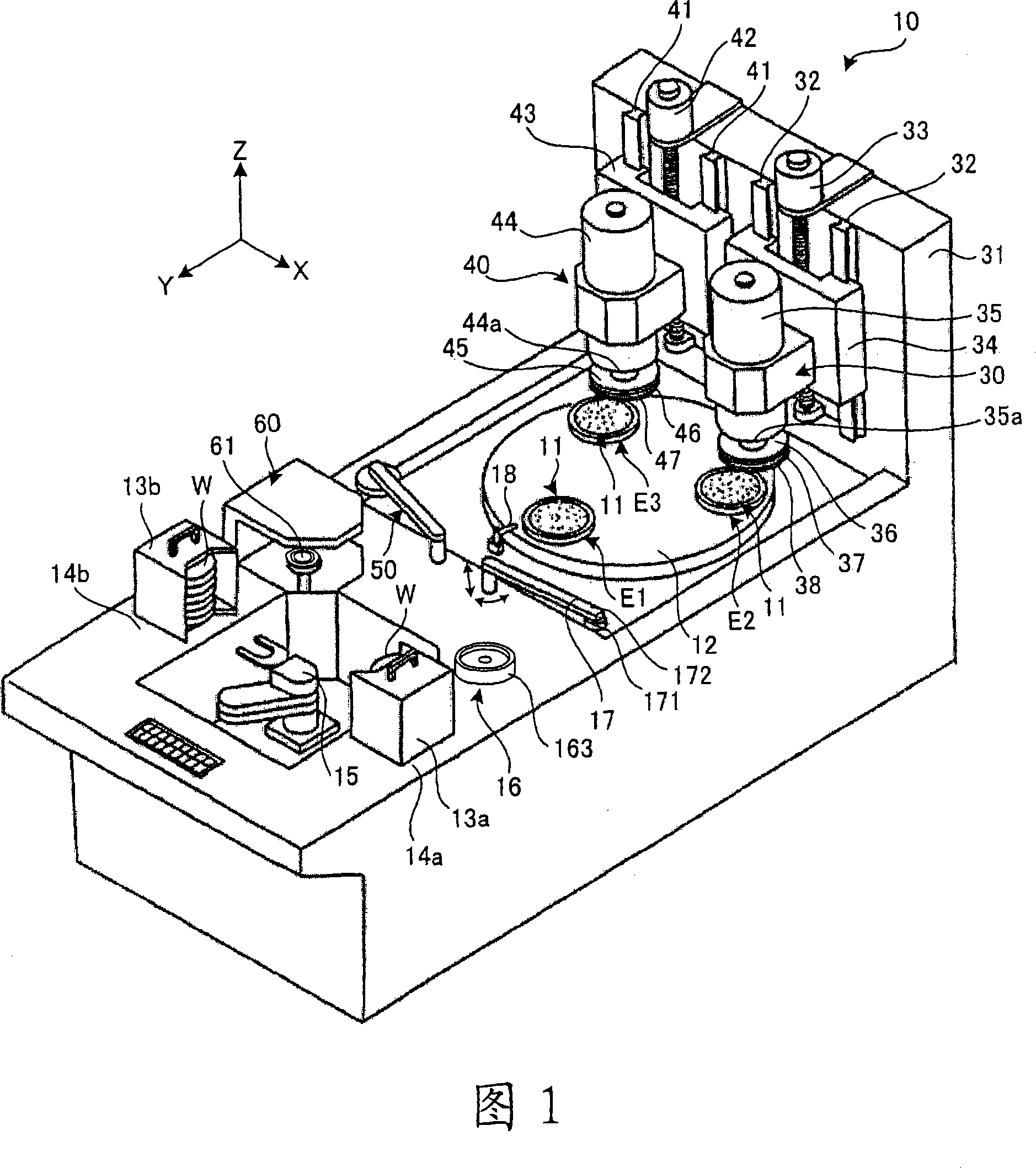

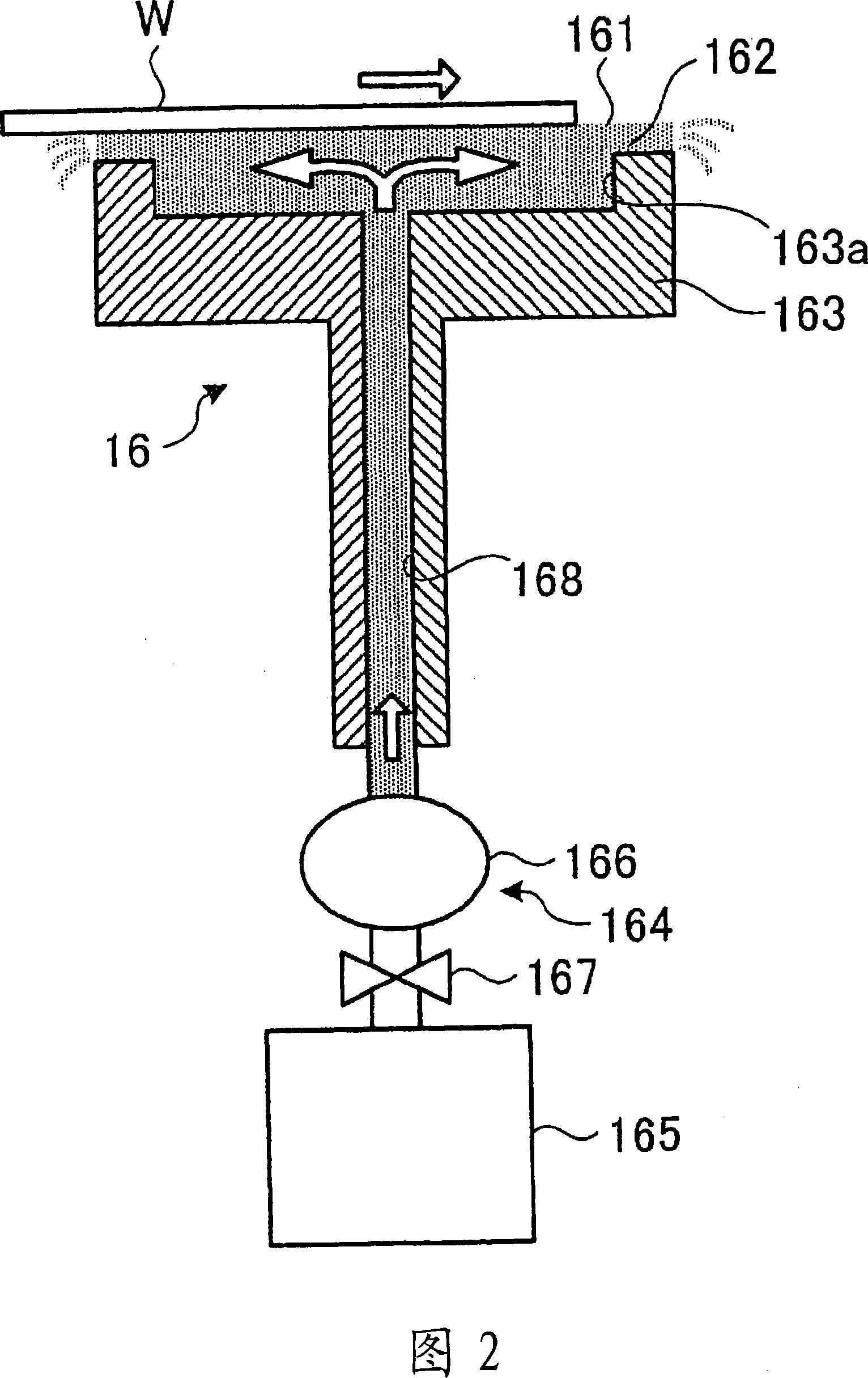

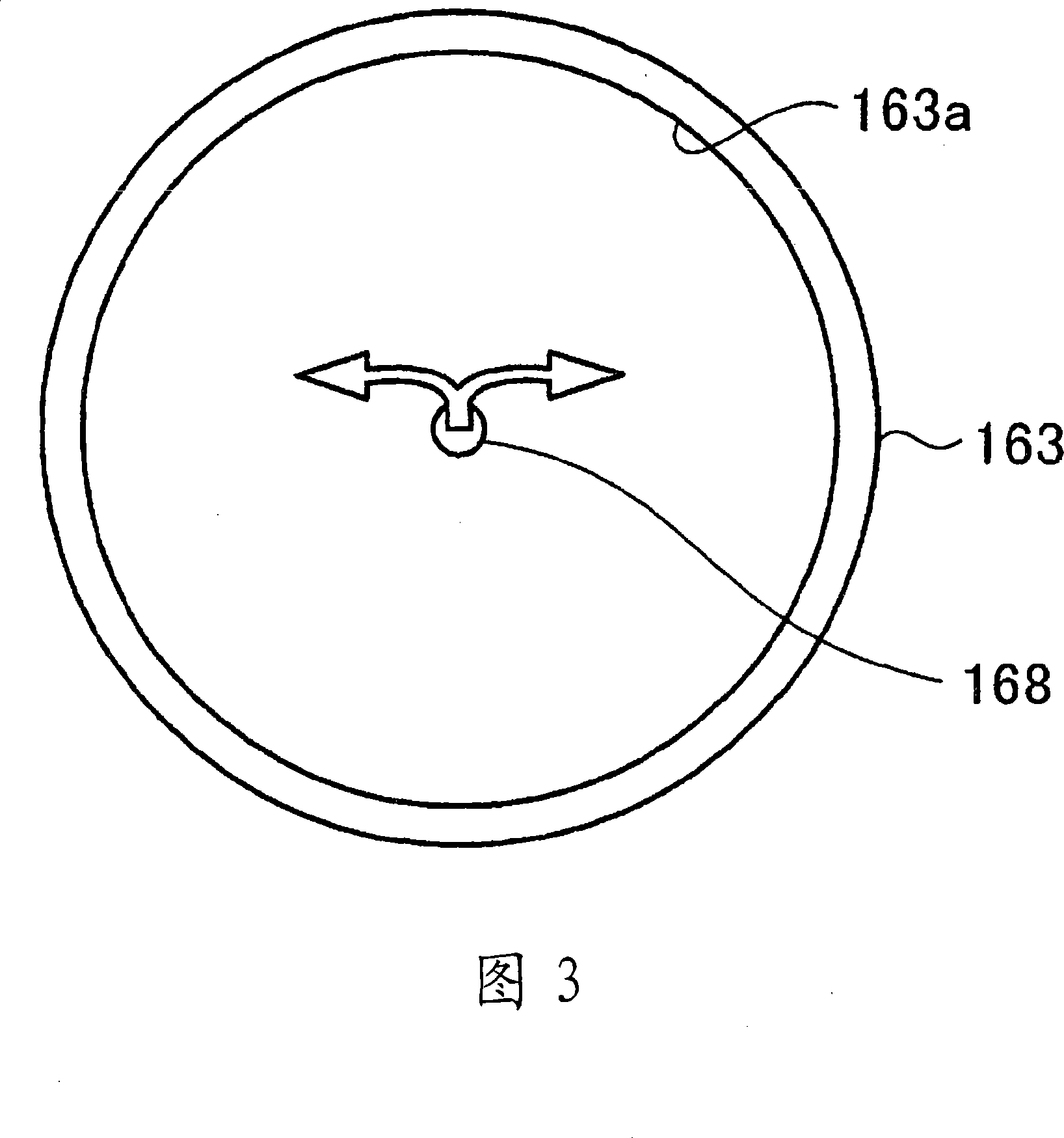

[0019] FIG. 1 is a perspective view showing the appearance of a grinding device that implements the wafer transfer method of the present embodiment. The grinding device 10 has: three chuck tables 11, which suck and hold the wafer W; a rotating rotating table 12, which supports the chuck tables 11 so as to be freely rotatable, respectively; and wafer cassette mounting portions 14a, 14b, which Wafer cassettes 13a and 13b containing wafers W are placed; a carry-in and unload unit 15 that unloads wafers W from wafer cassette 13a placed on the wafer cassette mounting portion 14a, and stores the ground wafer W into Placed in the wafer cassette 13b on the cassette placement portion 14b; positioning unit 16, which centrally positions the wafer W carried out by the carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com