Spot-checking plan scheduling control device

A control device and planning technology, applied in the direction of electrical program control, instrumentation, registration/instruction of machine work, etc., can solve the problems of refinement, insufficient standardization, insufficient standardized operation, and untraceability of plans, and achieve refinement. and normalization, minimization, and the effect of weakening correlations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

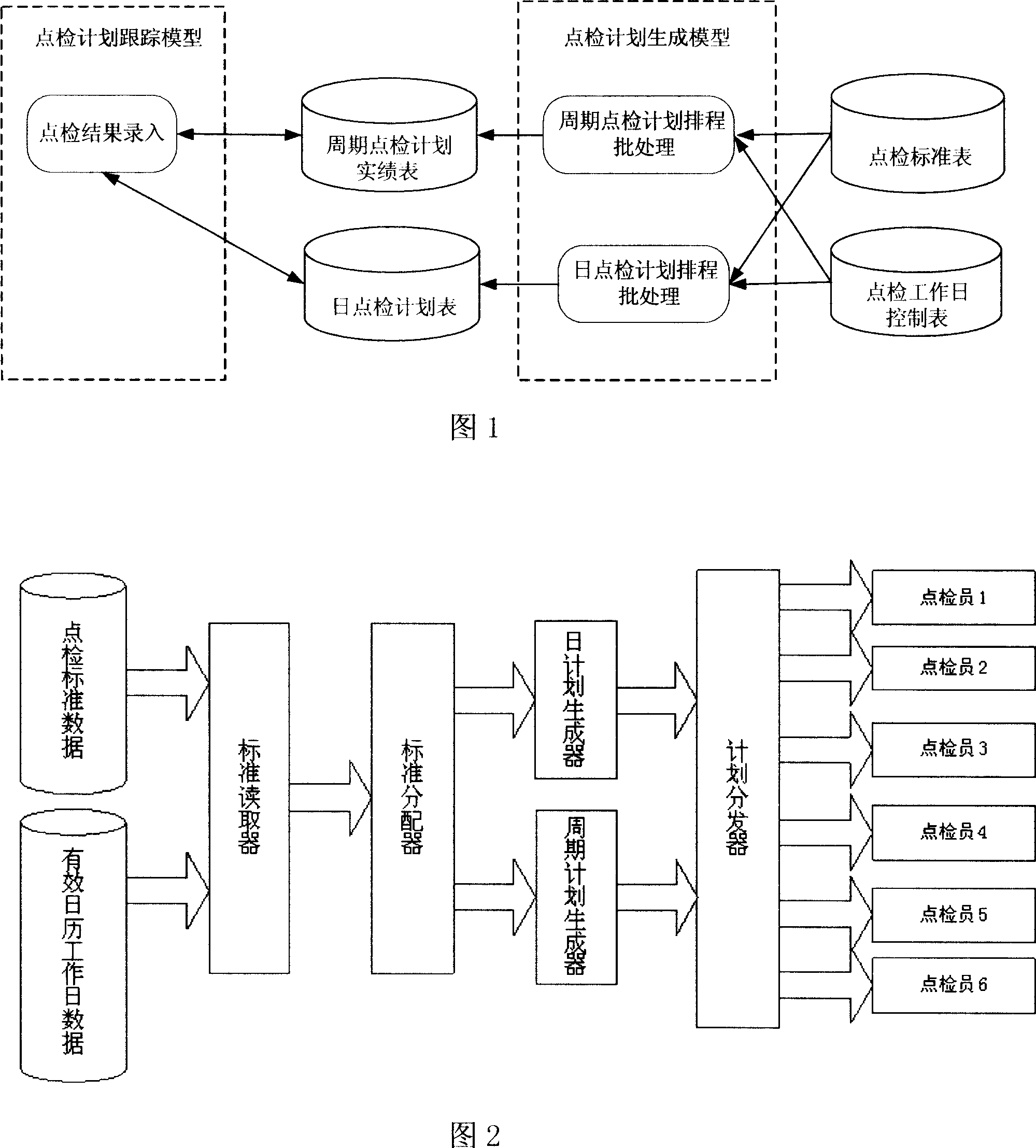

[0010] Generally speaking, daily inspection work can be divided into two types: periodic inspection and daily inspection. According to the different management division of each factory, this part of the work is performed by different personnel. In one case, the periodic inspection items are implemented by the full-time inspection personnel in charge of the equipment, accounting for 30-40% of the entire workload, while the daily inspection items (including shifts) are implemented by the production personnel of the equipment operator (low skill requirements), accounting for 70% of the entire workload. In another case, the full-time inspection personnel in charge of the equipment combine periodic inspection items (accounting for 30% of the entire workload) and daily inspection items (accounting for 70% of the entire workload, with high skill requirements) to implement. In order to suit two different situations, the inspection items that must be implemented by full-time inspecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com