Draining pump of air-conditioning plant

A drainage pump and pump body technology, which is applied to pump devices, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of reduced blade efficiency and low workmanship efficiency, and achieve improved drainage efficiency, elimination of disturbance, and The effect of expanding the inner wall area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

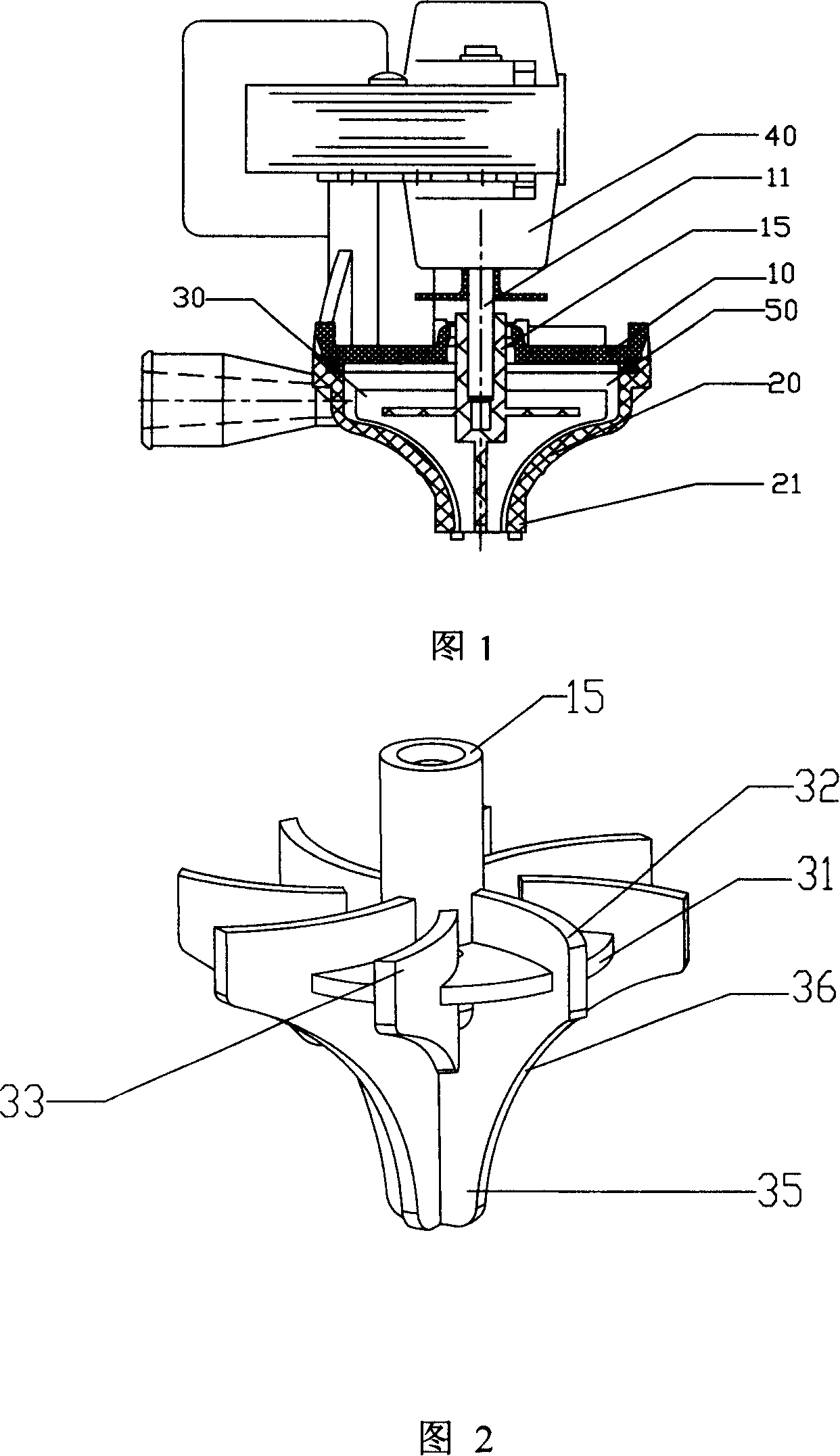

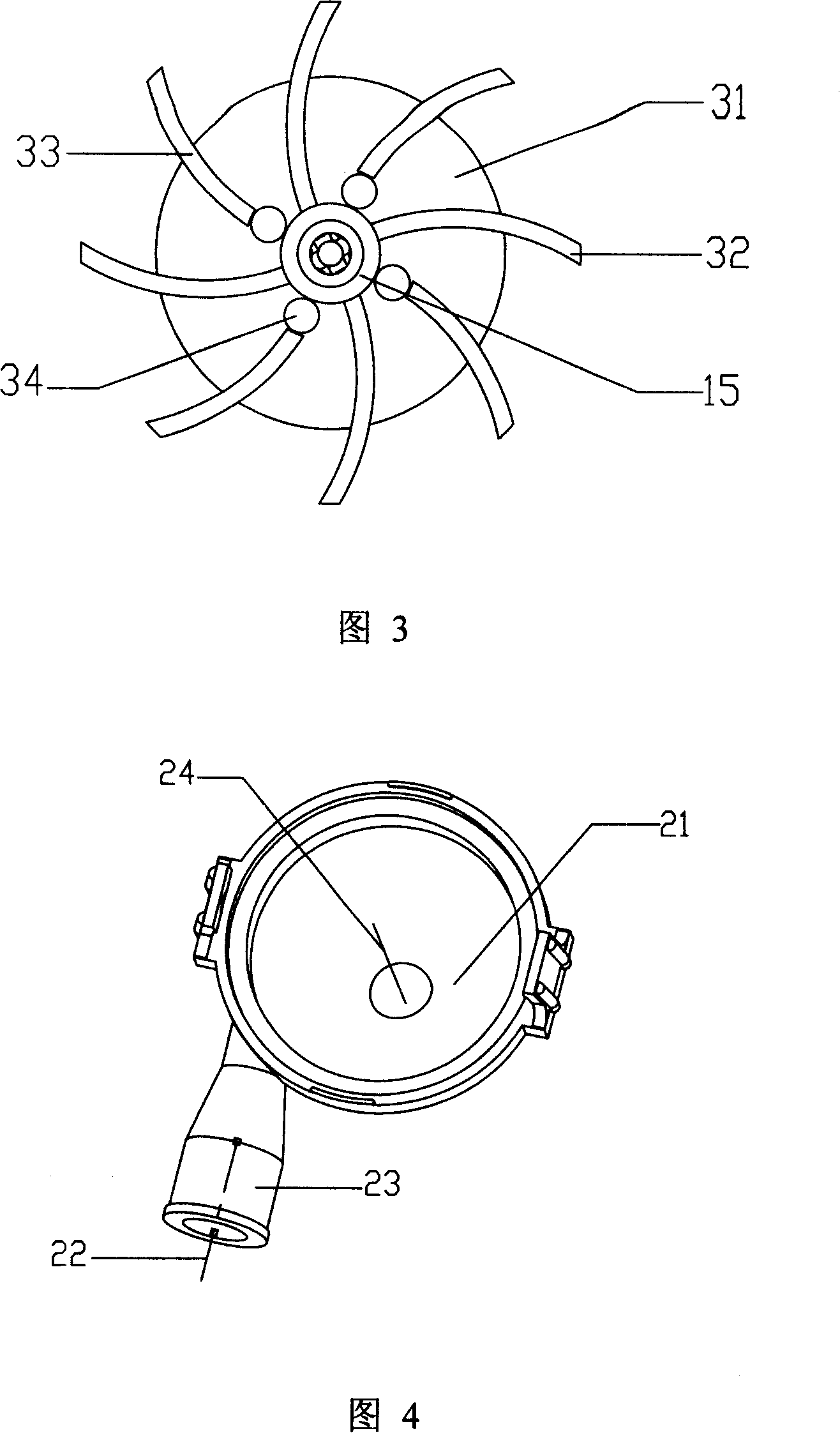

[0026] Fig. 1 is a structural schematic diagram of the present invention. The drainage pump of the present invention includes an upper pump body 10, a lower pump body 20, an impeller 30 installed in the chamber 50 formed by the upper pump body 10 and the lower pump body 20, and a motor 40 that drives the impeller 30 to rotate. 11 is the motor 40 The output shaft, the output shaft 11 is sleeved in the shaft sleeve 15 of the impeller 30 . The bottom of the impeller 30 stretches into the water inlet 21 of the lower pump body.

[0027] Fig. 2 is a three-dimensional structure diagram of the impeller. At the bottom of the axle sleeve 15, there is a disc 31 centered on the axle sleeve. The arrangement of the disc 31 strengthens and strengthens the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com