Ion exchange method for preparing lithium type low silicon aluminum X-shape zeolite molecular sieve

A zeolite molecular sieve and ion exchange technology, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems that the impact has not been well resolved, few applications and reports, and harsh exchange conditions. To achieve the effect of overcoming uneven exchange, process simplification, and high exchange degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

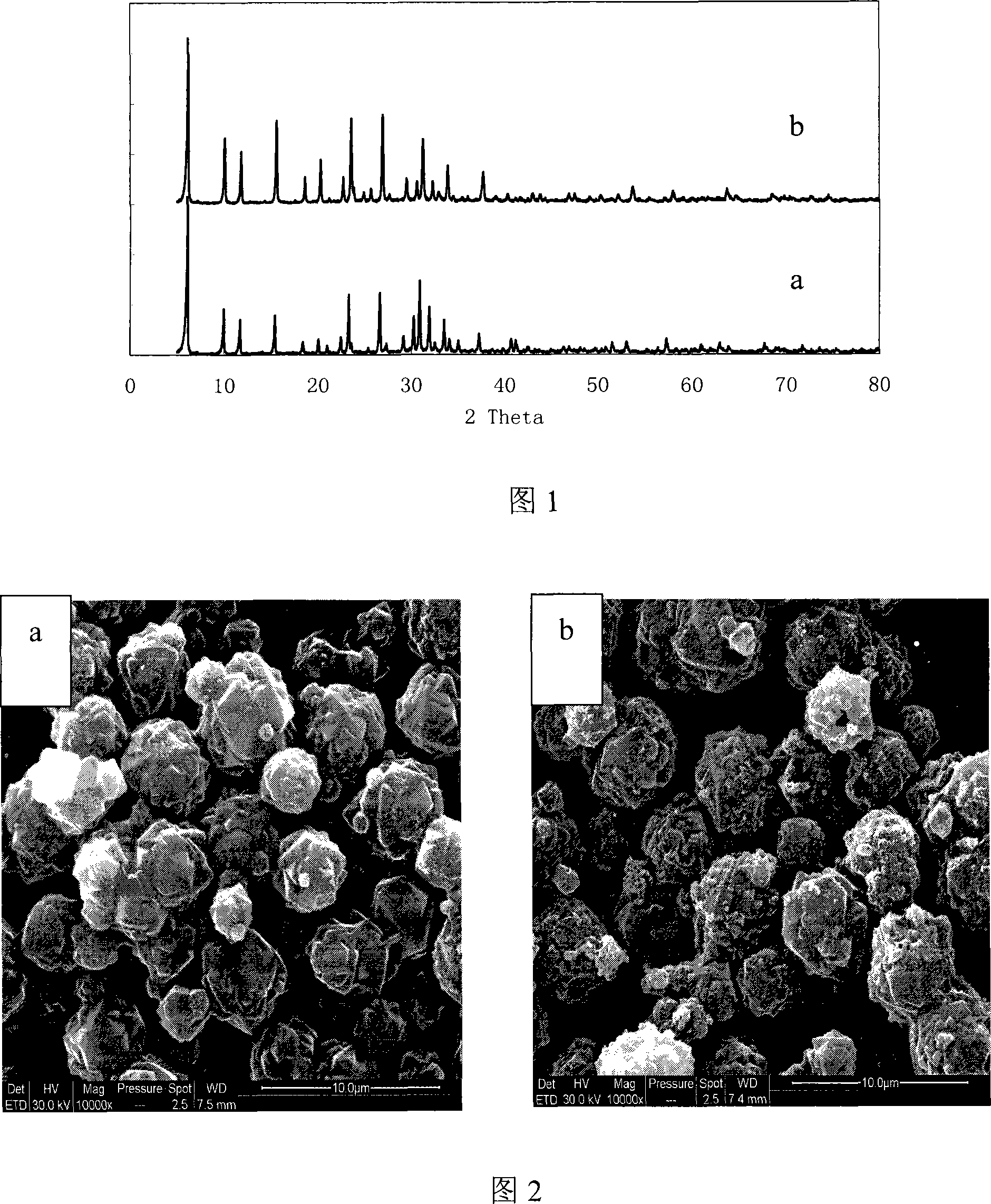

Embodiment 1

[0018] Take 5g of activated Na-LSX zeolite molecular sieve, mix it with 100ml of LiCl solution with a concentration of 0.4mol / L, place it in a water bath at 90°C for 2 hours, then filter it with suction and wash it. The obtained sample was re-added to 100 ml of the above LiCl solution for a second exchange. After the end, the sample was dried at 100°C for 2 hours and fired at 450°C for 1 hour.

[0019] Weigh the above 2g molecular sieve sample, mix it with 0.156g LiCl solid, stir it evenly and put it into the muffle furnace. Raise the temperature to 200°C at a speed of 2°C / min, and keep the temperature constant for 2 hours; then rise to 300°C at a speed of 4°C / min, and keep the temperature constant for 5 hours, take out the sample, wash and filter, and keep the sample at 150°C for 6 hours at a constant temperature After natural cooling, a Li-LSX zeolite molecular sieve sample with an exchange degree of 98% was obtained.

Embodiment 2

[0021] Take 5g of activated Na-LSX zeolite molecular sieve, mix it with 100ml of LiCI solution with a concentration of 0.4mol / L, place it in a water bath at 90°C for 2 hours, then filter it with suction and wash it. The obtained sample was re-added to 100 ml of the above LiCl solution for a second exchange. After the end, the sample was dried at 100°C for 2 hours and fired at 450°C for 1 hour.

[0022] Weigh the above 2g molecular sieve sample, mix it with 0.156g LiCl solid, stir it evenly and put it into the muffle furnace. Heat up to 200°C at a speed of 2°C / min, and keep the temperature constant for 2 hours; then rise to 400°C at a speed of 4°C / min, keep the temperature at 3 hours, take out the sample, wash and filter, and keep the sample at 150°C for 6 hours After natural cooling, a Li-LSX zeolite molecular sieve sample with an exchange degree of 98% was obtained.

Embodiment 3

[0024] Take 5g of activated Na-LSX zeolite molecular sieve, mix it with 100ml of LiCl solution with a concentration of 0.4mol / L, place it in a water bath at 90°C for 2 hours, then filter it with suction and wash it. The obtained sample was re-added to 100 ml of the above LiCl solution for a third exchange. After the end, the sample was dried at 100°C for 2 hours and fired at 450°C for 1 hour.

[0025] Weigh the above 2g molecular sieve sample, mix it with 0.052g LiCl solid, stir it evenly, put it into the muffle furnace, set the temperature program as follows: under room temperature, raise the temperature to 120°C at a speed of 1°C / min, and keep the temperature constant for 2 hours; Raise the temperature to 200°C at a speed of 2°C / min, and keep the temperature constant for 2 hours; then raise it to 350°C at a speed of 4°C / min, keep the temperature at 3 hours, take out the sample, wash and filter, and keep the sample at 150°C for 6 hours at a constant temperature After natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com