Microchannel speed distribution measuring apparatus and method

A velocity distribution and measurement device technology, which is applied in the direction of fluid velocity measurement, measurement device, velocity/acceleration/impact measurement, etc., can solve the problems of unsatisfactory observation and fluorescent particle observation, and achieve high adjustment accuracy and high spatial resolution , The effect of high optical detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

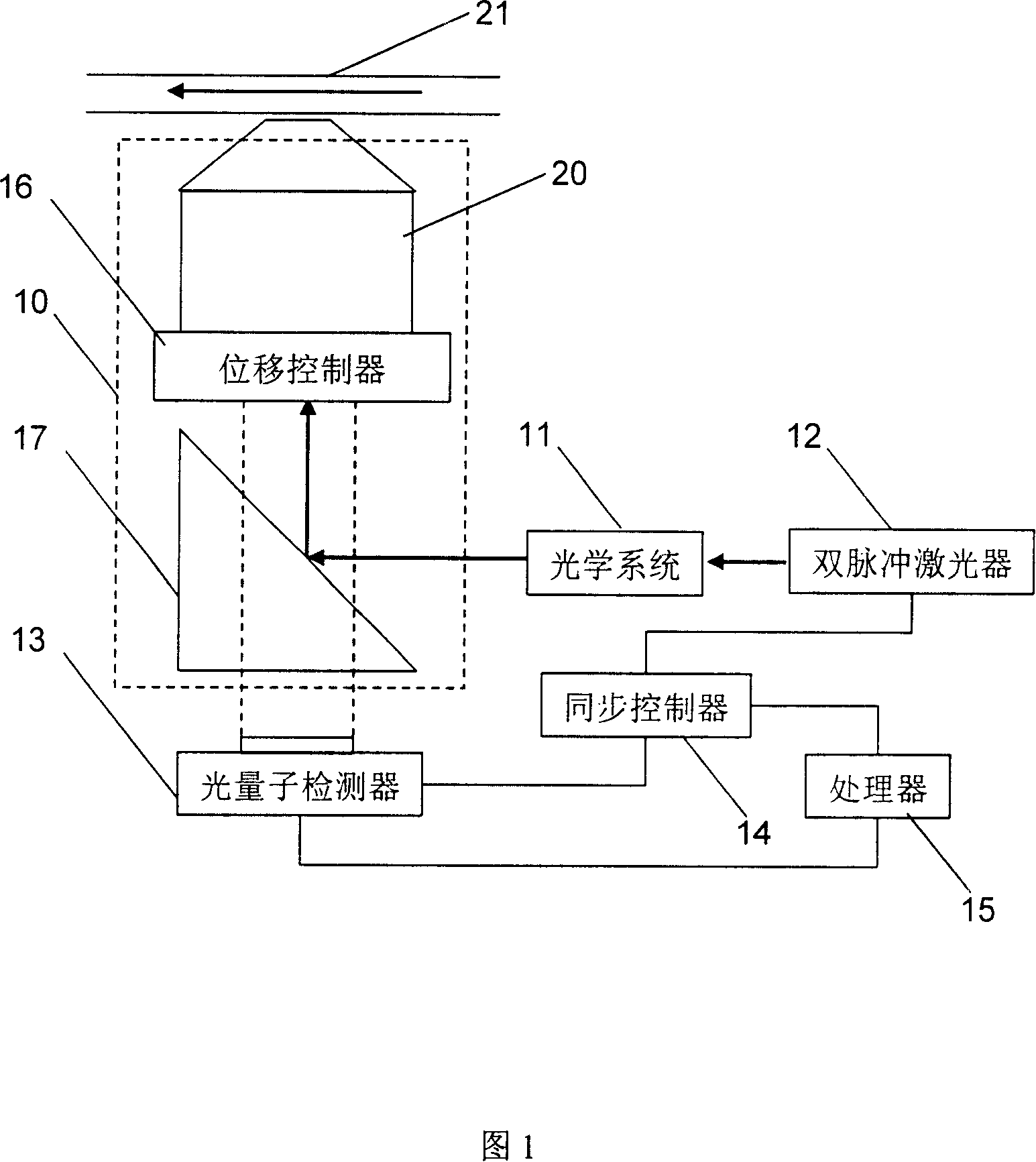

[0034] Referring to Fig. 1, make the schematic diagram of the measuring device of the microchannel velocity distribution of the present invention. Among them, microscope 10 adopts Olympus IX71 inverted fluorescence microscope, has white light and UV light dual light source, has 10X, 40X, 60X and 100X objective lens 20, wherein 100X is oil lens, numerical aperture NA=1.35, lens oil refractive index n=1.516, Optical resolution δ = 0.35μm, working distance is 100μm. The reflection device 17 adopts a right-angle reflection prism.

[0035] The optical system 11 adopts commercially available conventional focusing lens and collimating lens products.

[0036] Double-pulse laser 12 adopts NewWave Solo PIV120, Nd:YAG double-pulse laser, emission wavelength λ=532nm, pulse frequency adjustable from 1-15Hz, spot diameter 5mm, pulse width 3-5ns, maximum las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com