Artificial feather and manufacturing method

A technology of artificial feathers and wings, which is applied to clothing, sports accessories, etc., can solve the problems of elasticity, poor recovery, easy deformation, and large specific gravity, and achieve the effects of not easy to deform, light in specific gravity, and not easy to fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

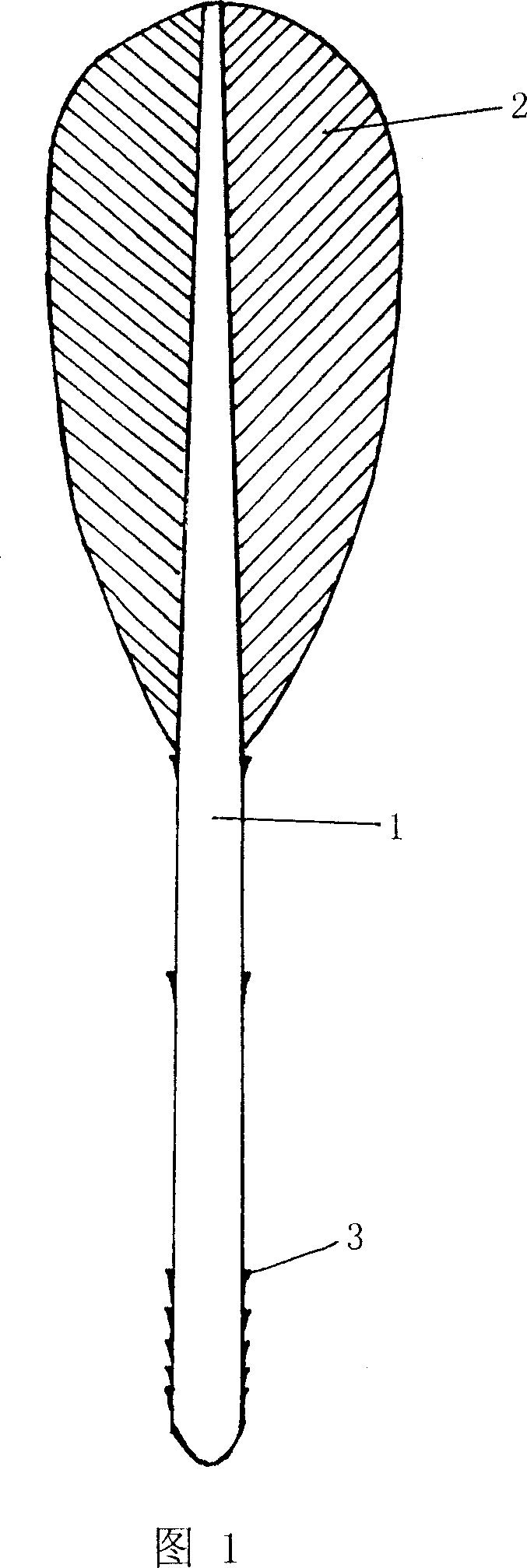

[0010] With reference to accompanying drawing 1, a kind of artificial feather is made of polypropylene (PP) material, and it comprises a wing bar 1 and fin 2, and wing bar 2 is fixed on the head of wing bar 1, is provided with at the afterbody of wing bar 1 Several barbs 3.

[0011] The manufacturing method of the artificial feather of the present invention is as follows: the feather is made of polypropylene (PP) material through heating and plasticizing, pressurized flow, cooling and solidification, and one-time injection molding.

Embodiment 2

[0013] With reference to accompanying drawing 1, a kind of artificial feather is made of polyethylene (PE) material, and it comprises a wing bar 1 and fin 2, and wing bar 2 is fixed on the head of wing bar 1, and is set at the afterbody of wing bar 1 There are several barbs3.

[0014] The manufacturing method of the artificial feather of the present invention is as follows: the feather is made of polyethylene (PE) material through heating and plasticizing, pressurized flow, cooling and solidification and one-time injection molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com