Fume exhaustor air intake cover and ventilator using air intake cover

A technology for air intake hoods and range hoods, which is applied in applications, oil fume removal, household stoves, etc. It can solve problems such as poor oil guide effect of air intake hoods, unsatisfactory oil collection effects, and physical damage to cooking personnel, so as to increase concentration Smooth oil drainage, eliminate oil dripping phenomenon, improve the effect of dredging function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

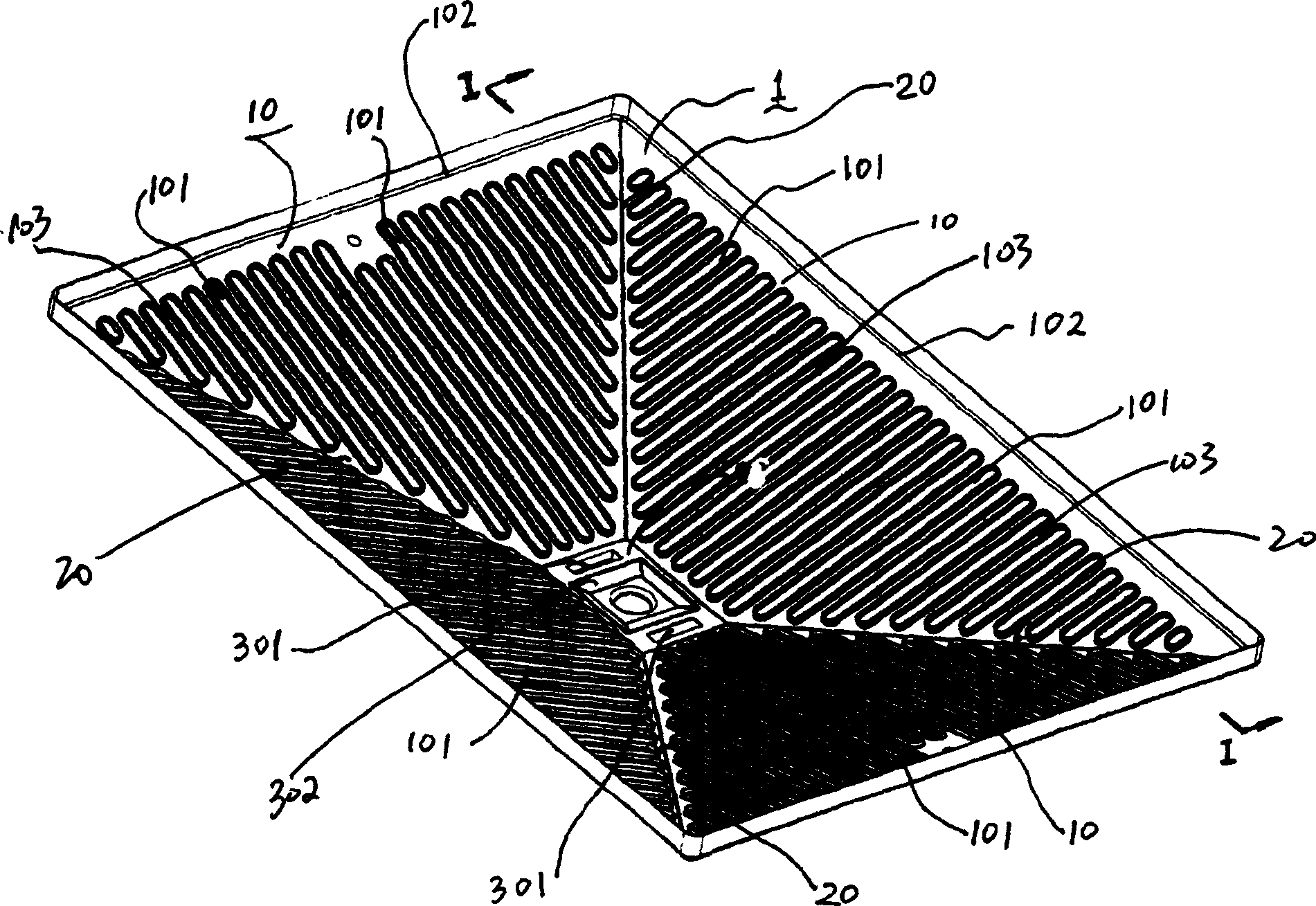

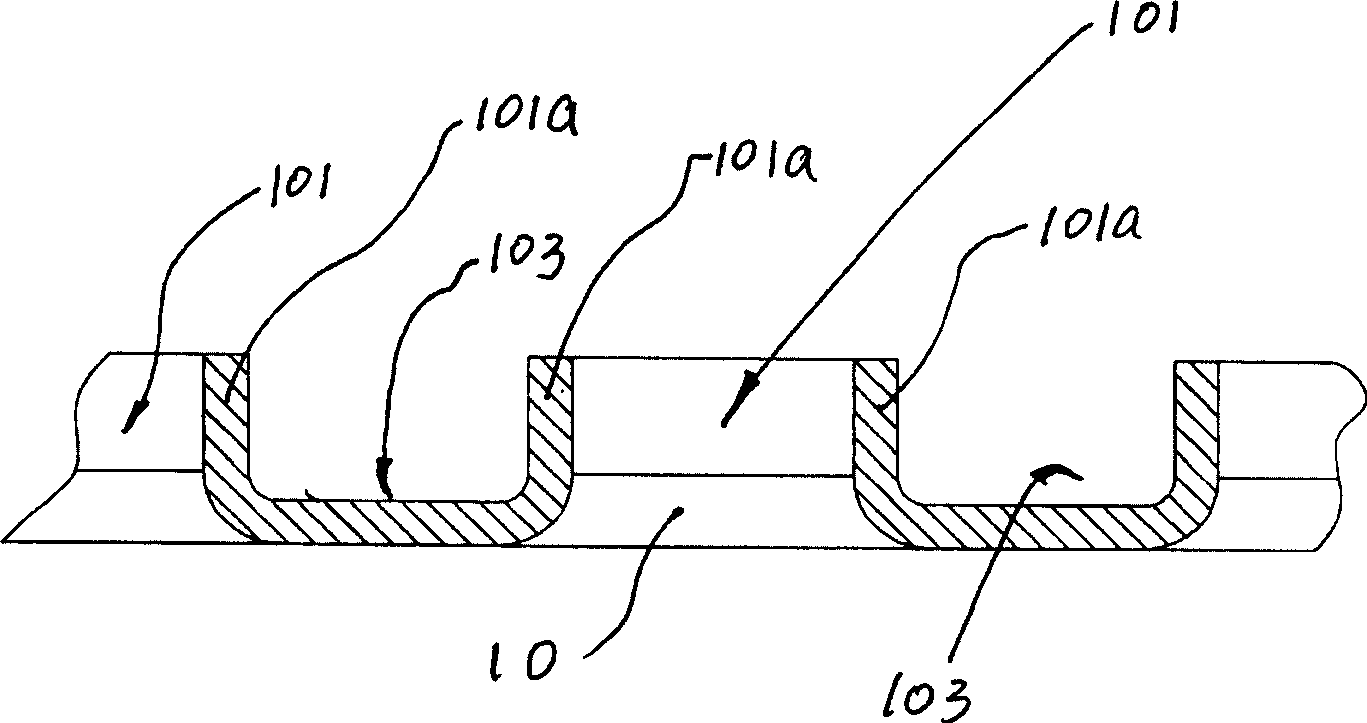

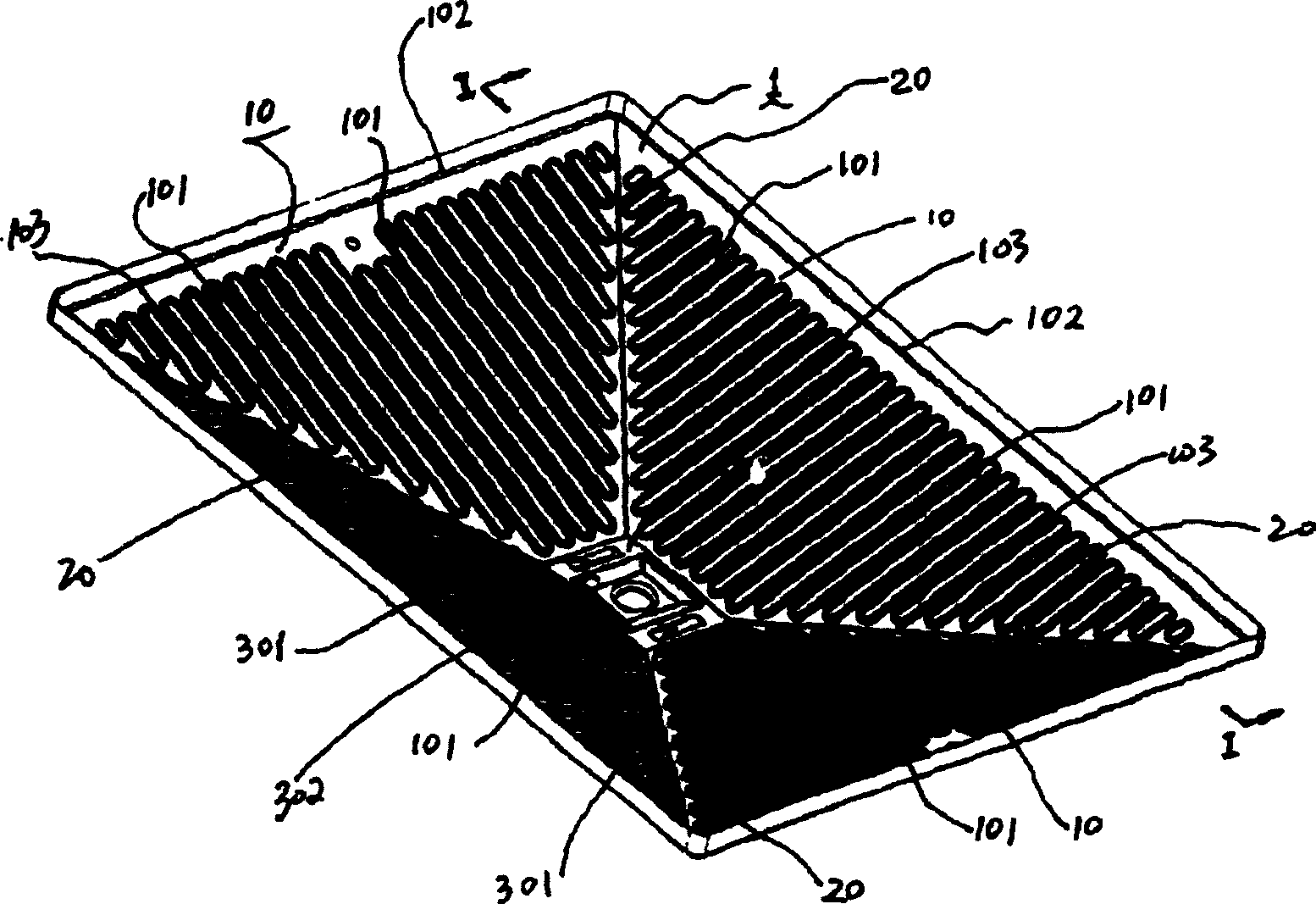

[0019] refer to figure 1 , the range hood 80 of the preferred embodiment of the present invention includes a housing, and the worm gear accommodated in the housing is connected with the air intake cover 1 on the downward housing part (not visible in the figure) of the range hood, the The air intake hood 1 is roughly in the shape of a truncated polyhedral cone with a large top and a small bottom, with an opening facing upwards, with an upper part 102 and a lower part 30, and four inclined surfaces 10 with holes connected between the upper part 102 and the lower part 30, A plurality of first oil guides 103 are distributed on each inclined surface 10 and pass through between the upper part 102 and the lower part 30 . A second oil guiding portion 20 is formed at the junction of two adjacent inclined surfaces 10 . The first oil guiding portion 103 may be a groove between the holes made by punching. In the best embodiment, the hole on the inclined surface 10 is an elongated flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com