Micro-wave oven furnace chamber inner container and processing method

A processing method and microwave oven technology, applied in heating methods, manufacturing tools, household stoves/stoves, etc., can solve the problems of substandard products, poor sealing, easy deformation, etc., and achieve high production efficiency, good quality, and low defective rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

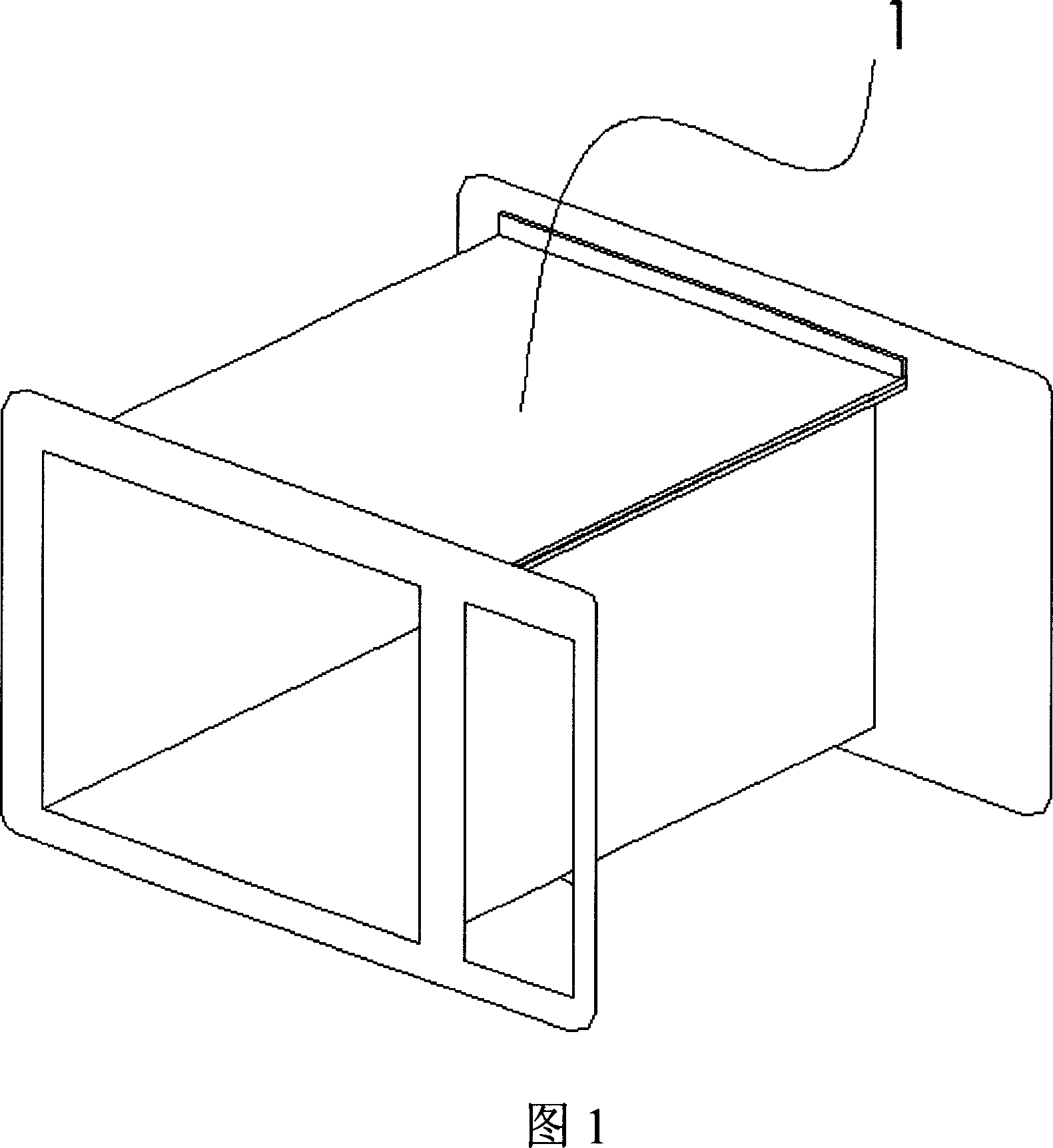

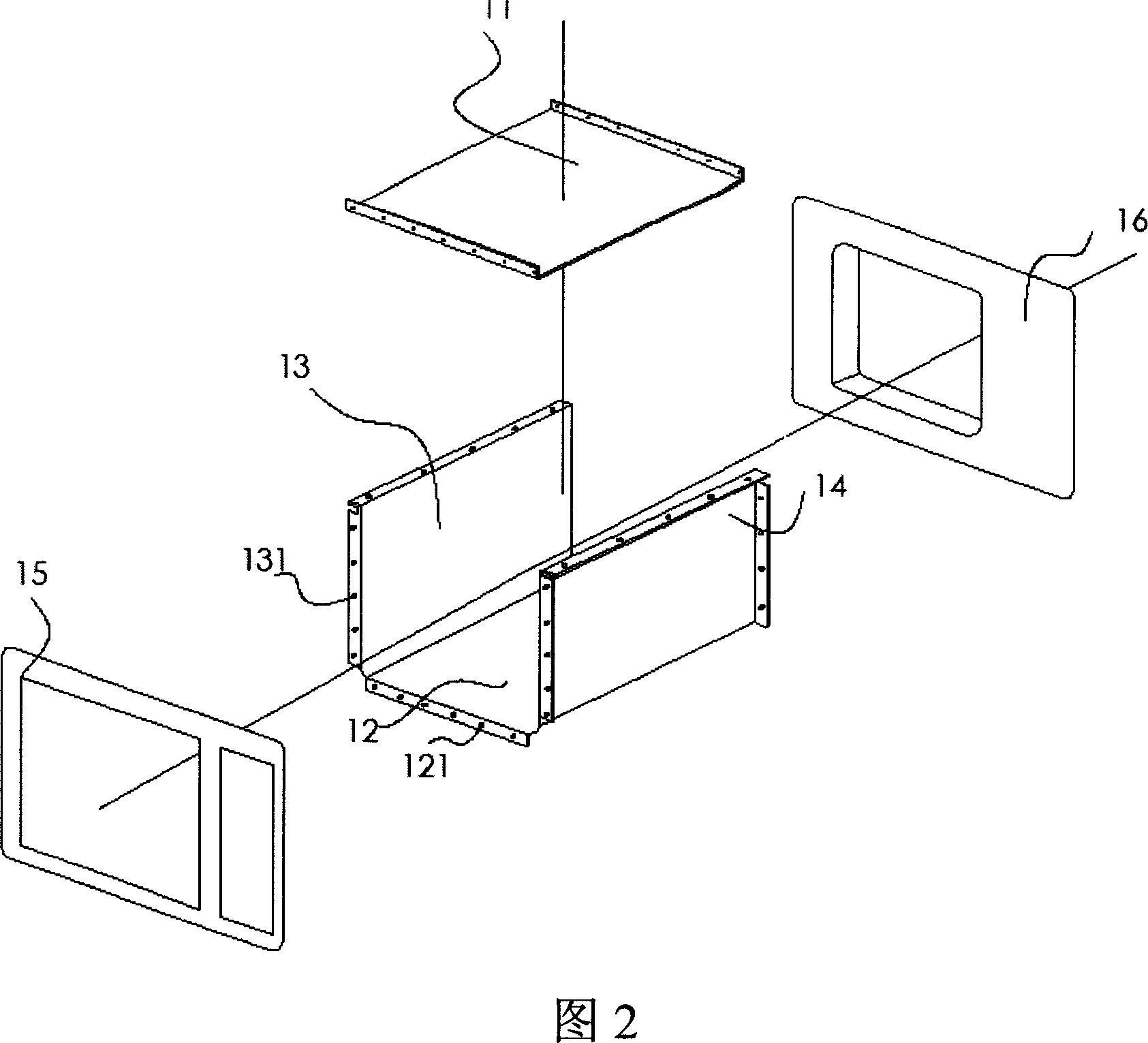

[0024] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

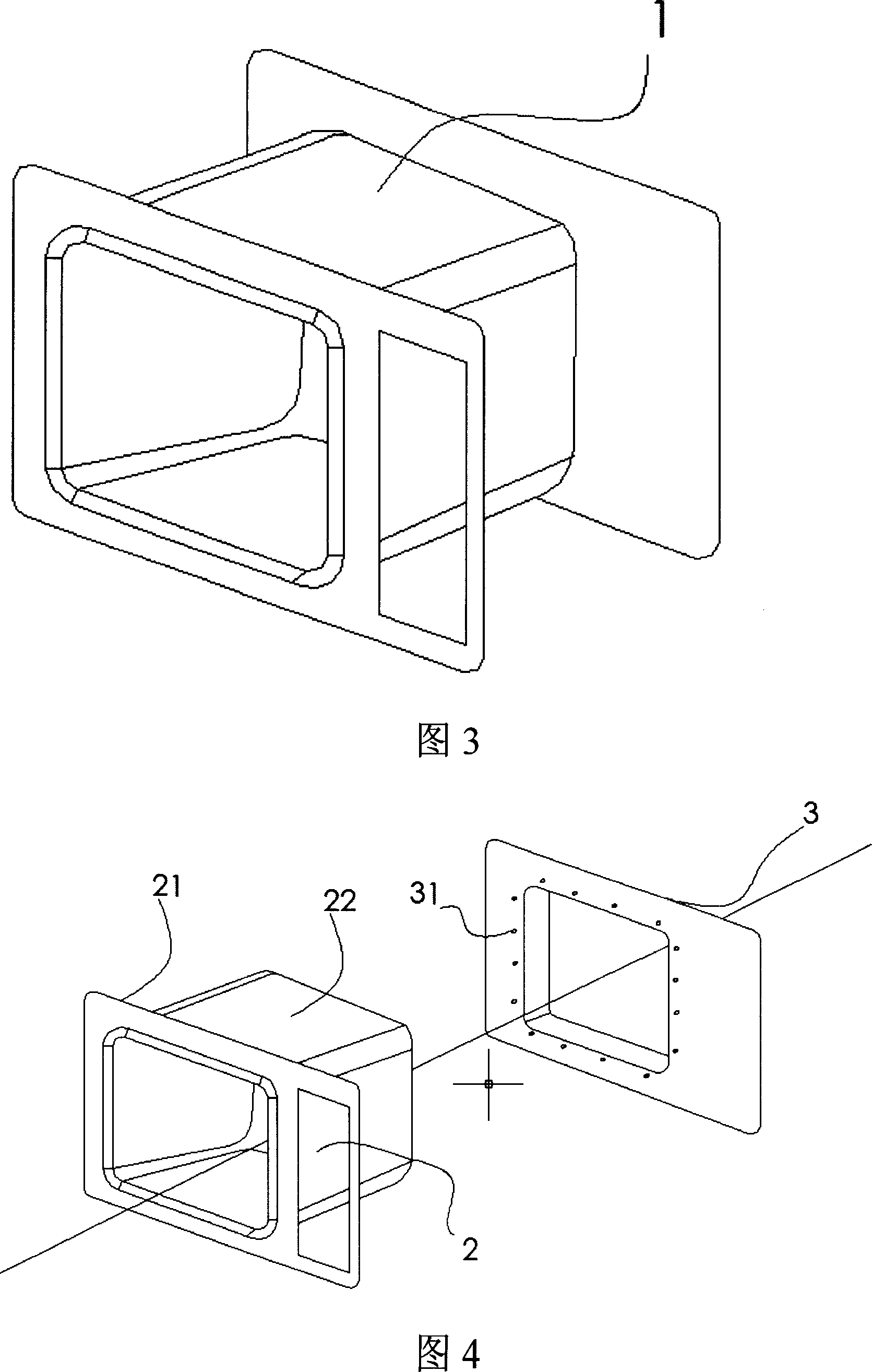

[0025] Please refer to Fig. 4, which is an exploded view of the structure of the inner container of the microwave oven cavity of the present invention. Due to the improvement of the stamping process level, the stamping depth of the parts formed by integral stamping is getting higher and higher, which is the basis and concept of the present invention. Starting point.

[0026] The present invention provides a microwave oven cavity liner, which is used in microwave ovens, and includes an integrally formed oven cavity liner body 2, a bracket connecting plate 3, and the integrally formed oven cavity liner body 2 includes a body front plate 21, and the cavity 22, the bracket connecting plate 3 is fixedly connected to the lower end of the integrally formed furnace cavity liner body 2.

[0027] The present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com