Method for manufacturing cobalt stibium antimonide based thermoelectric device

A technology of a thermoelectric device and a manufacturing method, which is applied to the connection of cobalt antimonide thermoelectric material and electrodes, and the preparation field of cobalt antimonide CoSb3-based thermoelectric devices, can solve the problems of no detailed report on the manufacturing process, and achieve good interface bonding and temperature rise. Fast speed and long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

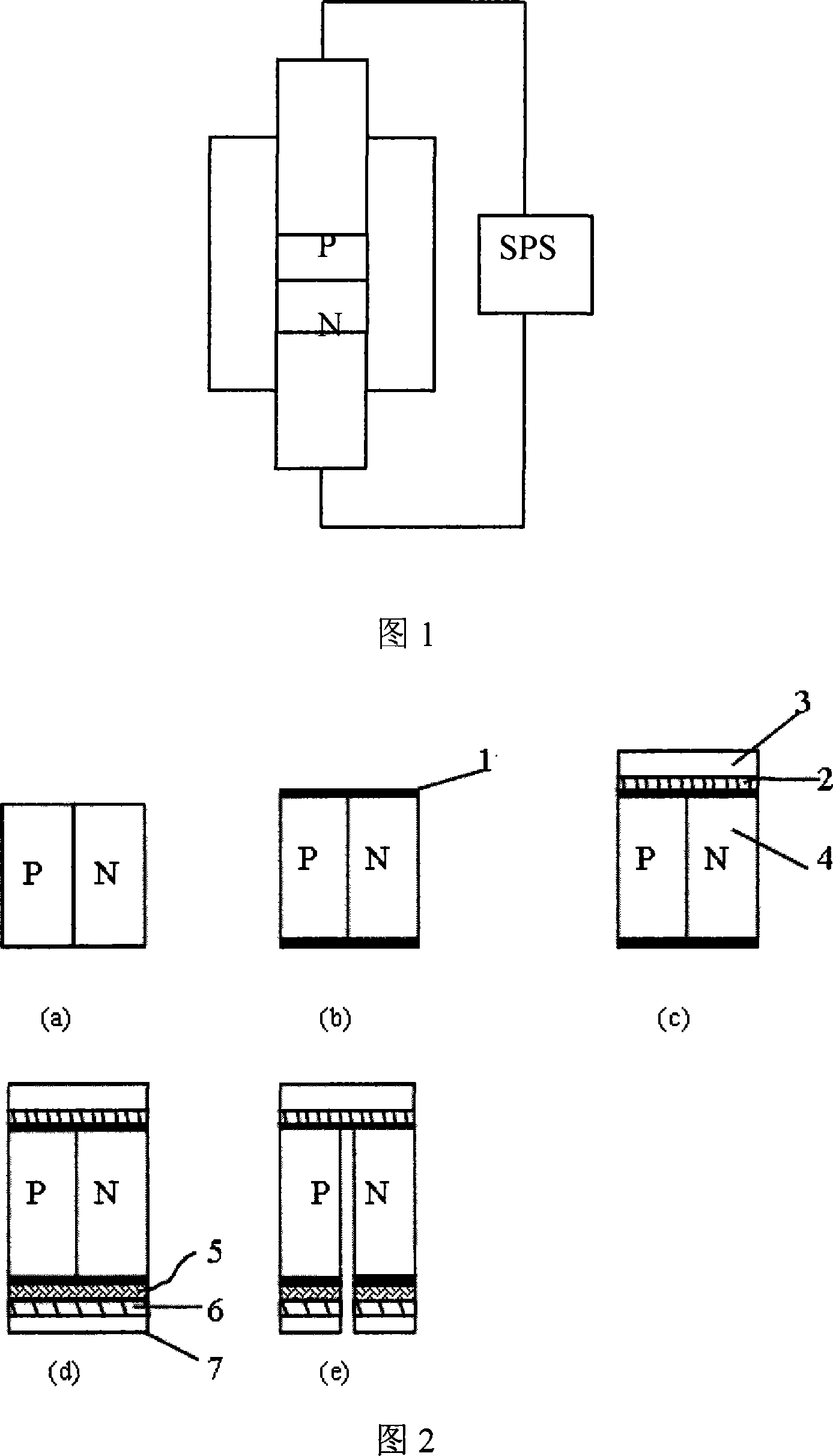

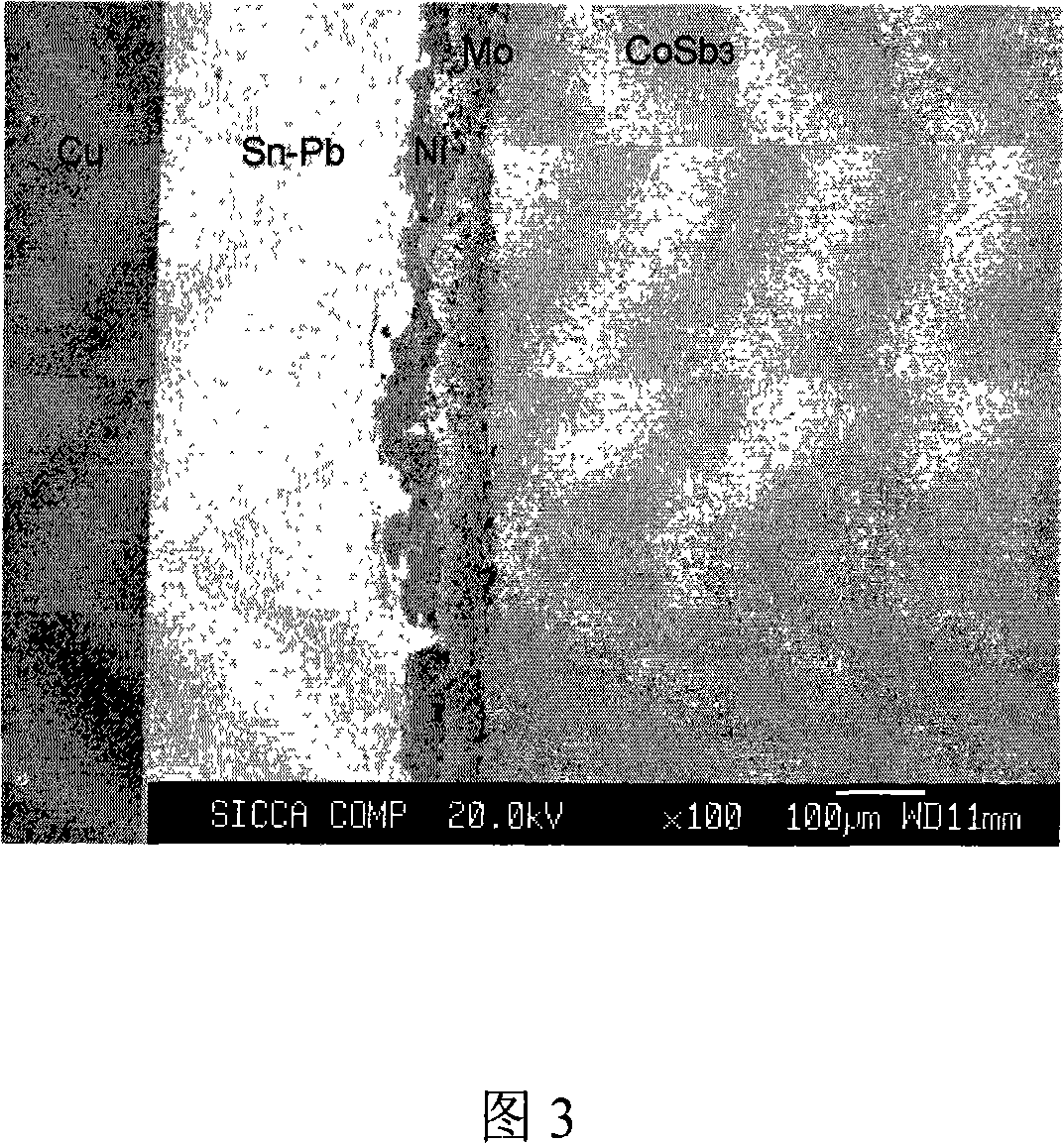

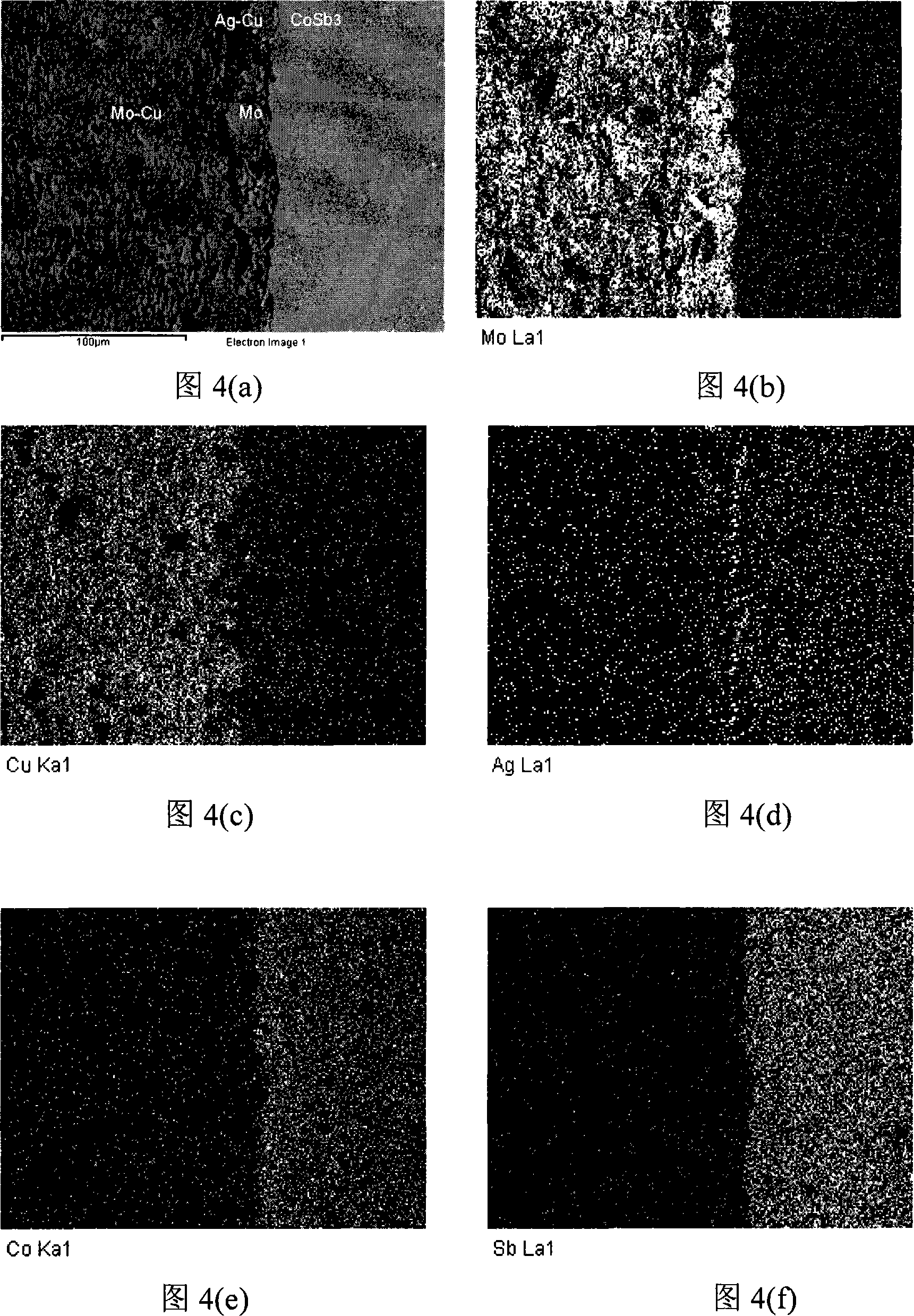

[0028]First, a 12×12×14mm P-N thermoelectric block was prepared in a square mold, and after being turned over 90°, the two end faces perpendicular to the PN interface were roughly ground to 12×12×12mm, and then ultrasonically cleaned in ethanol. Next, Mo was plasma-sprayed on both end surfaces for about 5 seconds to form a Mo diffusion barrier layer with a thickness of about 10 μm. Put the P-N type thermoelectric block back into the square mold, put the cut Ag-Cu solder piece and Mo-Cu electrode into the mold in turn on the P-N type thermoelectric block, and perform SPS connection. The sintering pressure is 15MPa, and the heating rate is 200°C / min, keep warm at 550°C for 30 seconds, then slowly lower the temperature, the cooling rate is controlled at 100°C / min, and the welding of the high-temperature end electrode is completed. Put the P-N type thermoelectric block connected with the high-temperature electrode on the Mo layer at the low-temperature end and then vacuum sputter ...

Embodiment 2

[0030] First, a P-N type thermoelectric block of 8×8×10 mm was prepared in a square mold, and after being turned over 90°, the two end faces perpendicular to the PN interface were roughly ground to 8×8×8 mm, and the same as in Example 1 Methods and conditions The P-N type thermoelectric block is treated and plasma sprayed, and the P-N type thermoelectric block is put back into the square mold, and the cut Ag-Cu soldering piece and Mo-Cu electrode are put into the mold in turn. P-N type thermoelectric block On the block, SPS connection is carried out, the sintering pressure is 20MPa, the heating rate is 250°C / min, the temperature is kept at 550°C for 45 seconds, and then the temperature is slowly lowered, and the cooling rate is controlled at 150°C / min, and the welding of the high-temperature end electrode is completed. Put the P-N type thermoelectric block connected with the high-temperature electrode on the Mo layer at the low-temperature end and then vacuum sputter a Ni layer...

Embodiment 3

[0032] First, a 6×6×8mm P-N thermoelectric block was prepared in a square mold, and after being turned over 90°, the two end faces perpendicular to the PN interface were roughly ground to 6×6×6mm, and the same as in Example 1 Methods and Conditions Treat the P-N type thermoelectric block, plasma spray W on both ends for about 5 seconds, and form a W diffusion barrier layer with a thickness of about 30 μm. Put the P-N type thermoelectric block back into the square mold, put the cut Ag-Cu solder piece and Mo-Cu electrode into the mold in turn on the P-N type thermoelectric block, and perform SPS connection. The sintering pressure is 15MPa, and the heating rate is 250°C / min, keep warm at 550°C for 60 seconds, then slowly lower the temperature, the cooling rate is controlled at 150°C / min, and the welding of the high-temperature end electrode is completed. Put the P-N type thermoelectric block connected with the high-temperature electrode on the Mo layer at the low-temperature end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com