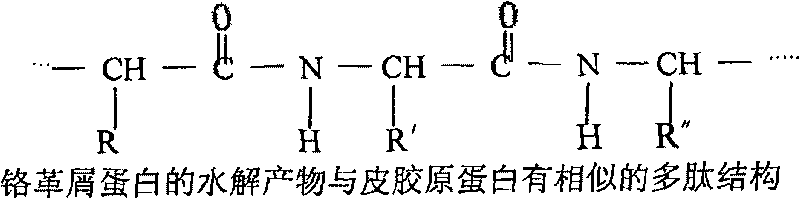

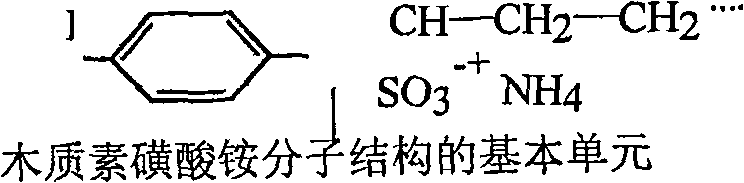

Preparation method of lignin-protein filled retanning agent for leather

A retanning agent and lignin technology, applied in the treatment of small hide/big hide/leather/fur, chemical treatment and application of small hide/big hide/leather/fur, and can solve secondary pollution and complicated process , high production cost and other issues, to achieve the effect of no secondary pollution, simple process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] First, add 0-140 parts by mass of water, 270 parts of chrome leather shavings and 65 parts of sodium hydroxide into the reactor, stir for 5 minutes, add the second part of 270 parts of chrome leather shavings and 60 parts of sodium hydroxide , stirred for 5 minutes, then added 270 parts of chrome leather shavings and 60 parts of sodium hydroxide in the third part, stirred for 20 minutes, and the reactant was a uniform paste. Add 72 parts of ammonium lignosulfonate, and continue stirring for 12 hours. Then 55 parts of formic acid are added dropwise in a trickle, and the control time is 3 hours, and 100 parts of sulfuric acid are added dropwise in a trickle, and the control time is 3 hours. Check the pH value of the 1:10 aqueous solution of the reactants to be 7.5 to 8.0. It should be noted that the specific amount of water depends on the dryness and wetness of the chrome leather shavings. No water is added to fresh chrome leather shavings that have just been peeled off,...

Embodiment 2

[0018] First, add 0-140 parts by mass of water, 250 parts of chrome leather shavings and 65 parts of sodium hydroxide into the reactor, stir for 5 minutes, add the second part of 250 parts of chrome leather shavings and 65 parts of sodium hydroxide , stirred for 5 minutes, then added 250 parts of the 3rd part of chrome leather shavings and 60 parts of sodium hydroxide, stirred for 20 minutes, and the reactant was a uniform paste. Add 75 parts of ammonium lignosulfonate, and continue stirring for 12 hours. Then 60 parts of formic acid are added dropwise in a trickle, and the control time is 3 hours, and then 100 parts of sulfuric acid are added dropwise in a trickle, and the control time is 3 hours. Check the pH value of the 1:10 aqueous solution of the reactants to be 7.5 to 8.0.

Embodiment 3

[0020] First, add 0-140 parts by mass of water, 280 parts of chrome leather shavings and 60 parts of potassium hydroxide into the reactor, stir for 5 minutes, add the second part of 280 parts of chrome leather shavings and 55 parts of potassium hydroxide , stirred for 5 minutes, then added 280 parts of chrome leather shavings and 55 parts of potassium hydroxide in the third part, stirred for 20 minutes, and the reactant was a uniform paste. Add 70 parts of ammonium lignosulfonate, and continue stirring for 12 hours. Then add 50 parts of formic acid dropwise in a trickle for a control time of 3 hours, then add 80 parts of sulfuric acid dropwise in a trickle for a control time of 3 hours. Check the pH value of the 1:10 aqueous solution of the reactants to be 7.5 to 8.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com