Honeycomb core made in mechanized production and method for producing sandwich board by using said honeycomb core

A honeycomb core and honeycomb panel technology, which is applied in the field of building decoration materials, can solve the problems of low production efficiency, difficult operation, and difficulty in leveling the edge of the honeycomb core, and achieves the effect of short cutting distance, improved production efficiency, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0032] This embodiment relates to a specific method of honeycomb core production.

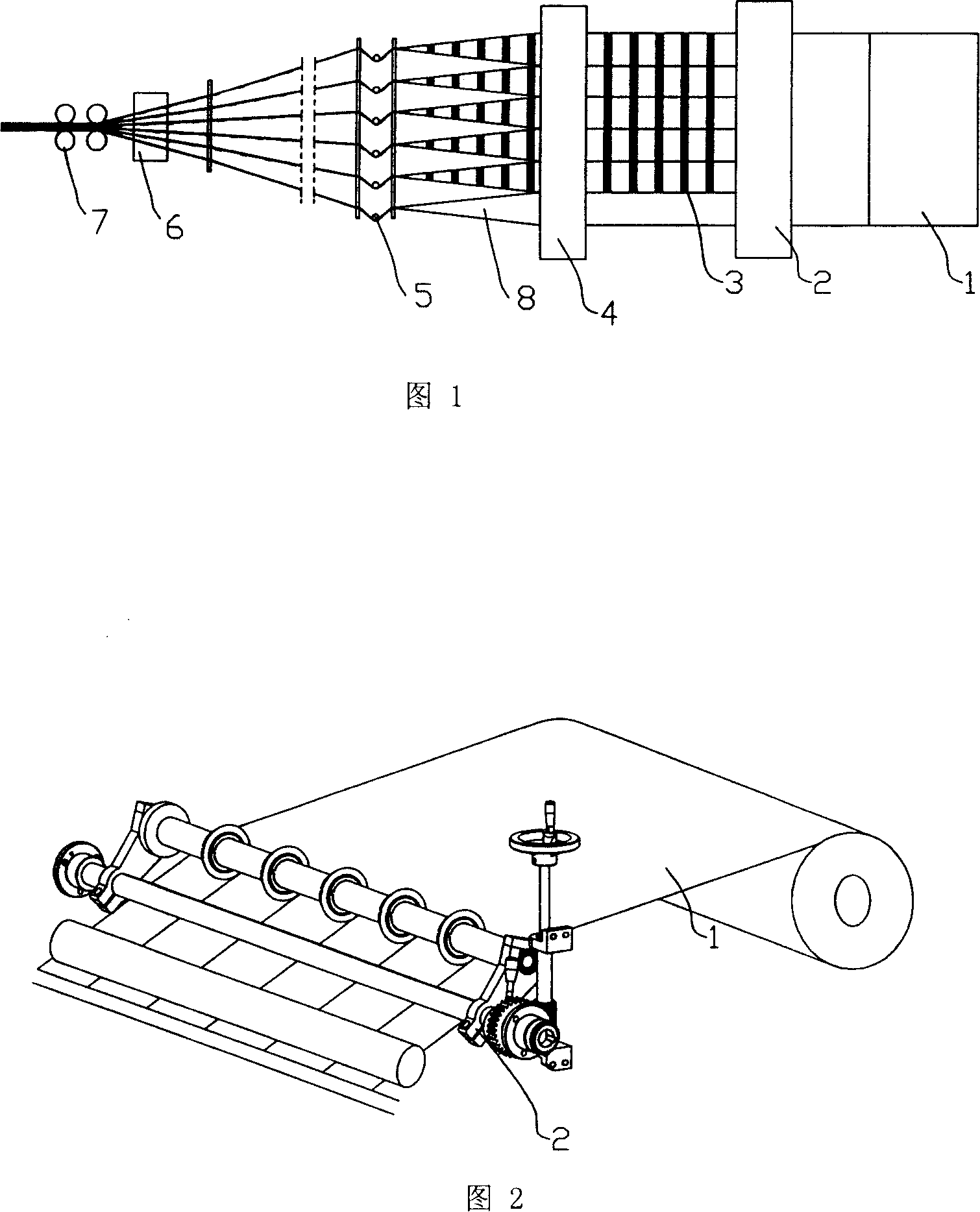

[0033] With reference to Fig. 1, present embodiment is the method applied when sheet material 1 is rolled on a horizontally placed shaft, comprises the following process steps:

[0034] 1) Referring to FIG. 2 , the sheet 1 is rolled on a horizontal shaft, and the sheet 1 is made of aluminum material or plastic material or paper material. Expand the sheet 1, first apply some horizontal strip glue 3 on the sheet 1 with the glue applicator 2, and the spacing of the strip glue 3 is equal; this strip glue 3 is a kind of dry glue; then, use Slitting machine 4 cuts the layer of sheet 1 into several thin strips 8 with uniform width;

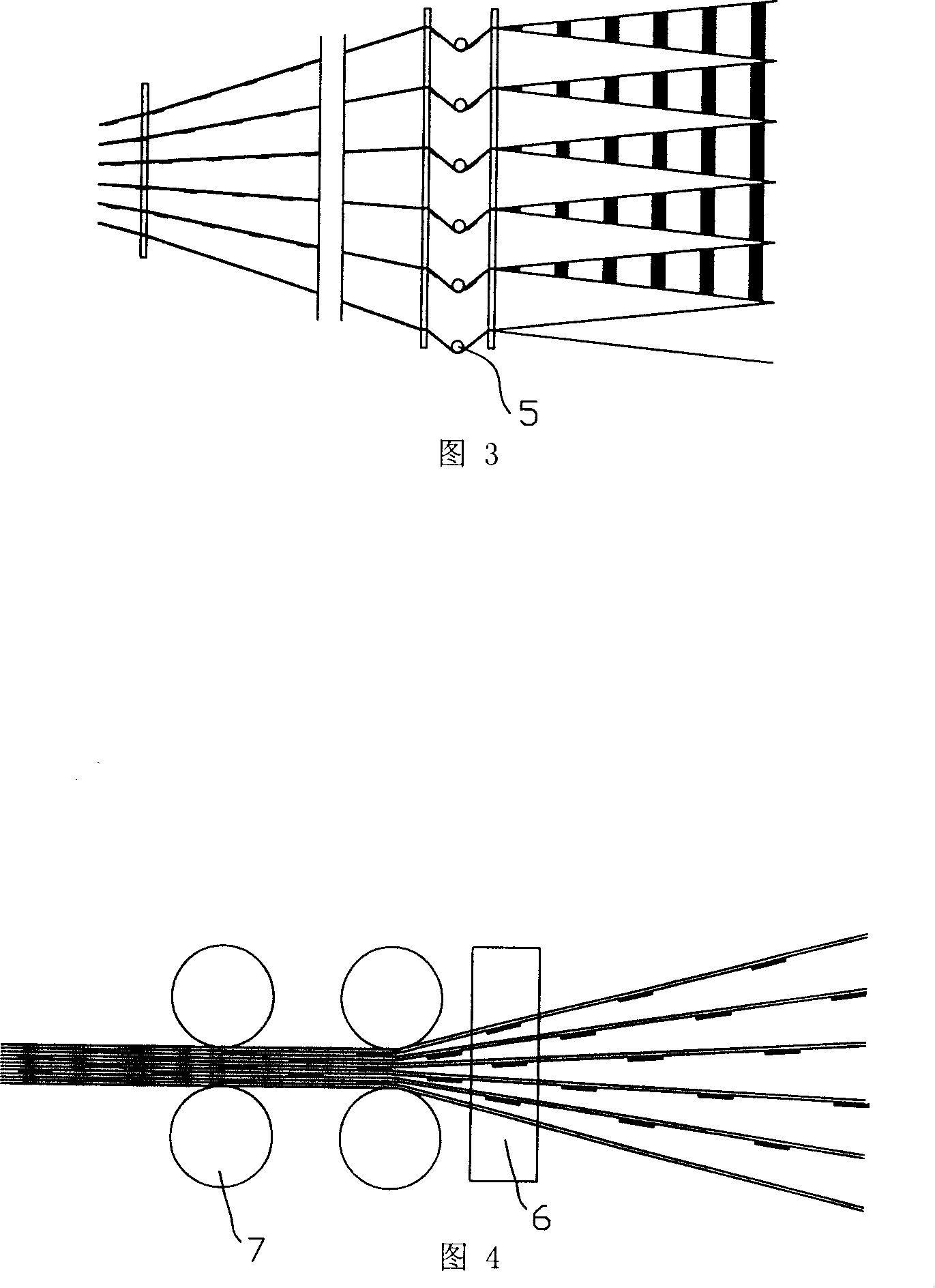

[0035] 2) With reference to Fig. 3, utilize the forming roller 7 of compound machine to pull all thin strips forward, polymerize thin strips 8, make all thin strips 8 stack together; Advance after passing a column 5, use the side of the column 5 of the positioning mecha...

specific Embodiment 2

[0038] The present embodiment relates to the production method of honeycomb panel, comprises following processing step:

[0039] 1) Prepare the panel and bottom plate of the honeycomb panel. The panel and the bottom plate are in block shape, and use a glue applicator to coat the inner surface of the panel and the bottom plate with viscous glue or attach a hot-melt adhesive film layer;

[0040] 2) cutting off the honeycomb core obtained by the above-mentioned production method of the honeycomb core with a cutting machine, the length of the cutting matches the length of the panel and the bottom plate;

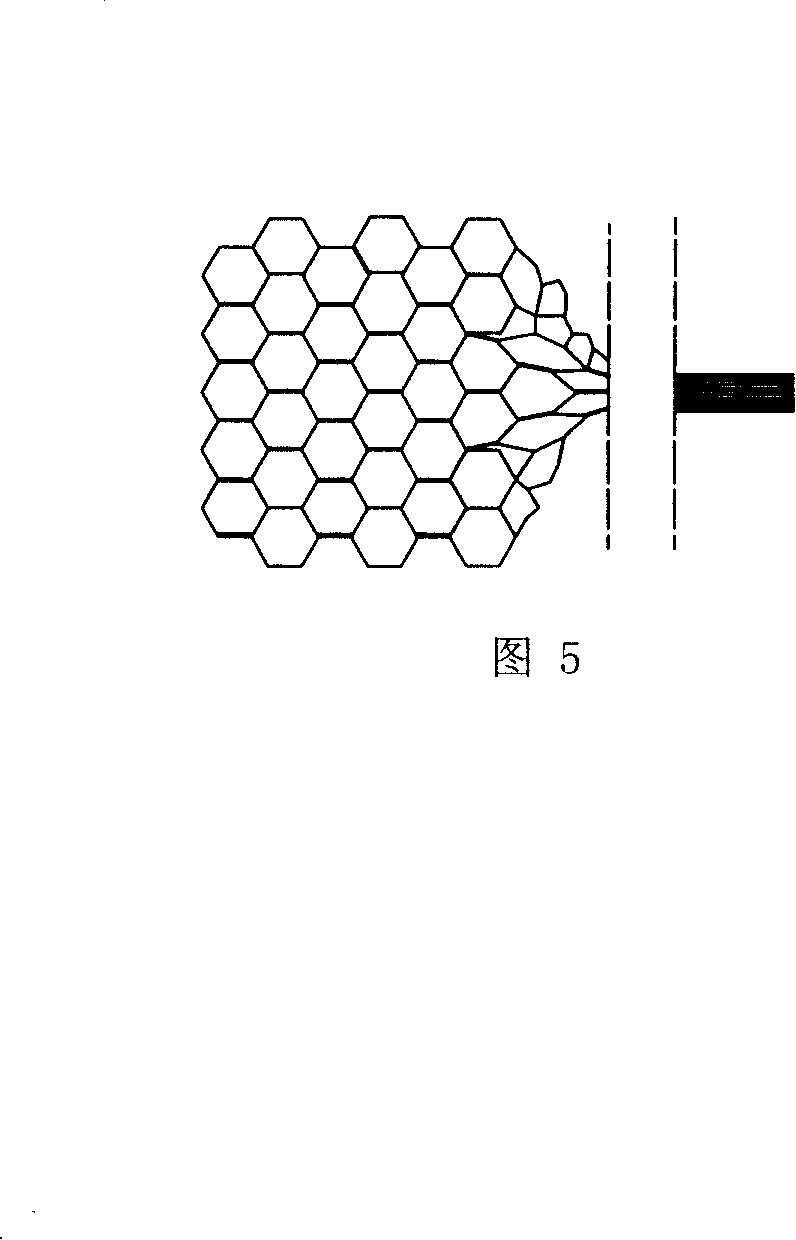

[0041] 3) With reference to Fig. 5, the honeycomb core after cutting is pulled apart horizontally, the bottom of the honeycomb core is pasted on the bottom plate with the viscous glue on the inner surface of the bottom plate, and the bottom of the honeycomb core is pasted on the bottom plate with the viscous glue on the inner surface of the panel; or , while heating the hot-melt ...

specific Embodiment 3

[0049] This embodiment relates to another production method of a honeycomb core, which is the method used when the sheet is rolled on a vertically placed reel. Including the following process steps:

[0050] 1) Roll the sheet on a vertically placed reel, unroll the sheet, and then divide the sheet into several thin strips with uniform width. One side of the sheet has horizontal strip glue, and the horizontal strip glue has a certain distance between each other. interval.

[0051] 2) Utilize the molding roller of the composite machine to pull all the thin strips forward. When the thin strips are polymerized, the aggregation point of the thin strips has a certain distance from the reel. Only after a relatively long distance can all the thin strips be stacked together. Before the thin strips are stacked, the relative positions of the thin strips are adjusted, and the thin strips are respectively bypassed by different columns, so that the ends of adjacent thin strips are separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com