Method for producing milling-ball by vacuum sealing and its shaped mould

A technology of vacuum sealing and grinding balls, which is used in casting molding equipment, casting molds, cores, etc., can solve the problems of poor process controllability, low production efficiency, and high labor intensity, and achieves reduced scrap rate, reasonable structure, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is not limited by the following examples, and the specific implementation manner can be determined according to the above-mentioned technical solutions and actual conditions of the present invention.

[0026] Below in conjunction with preferred embodiment and accompanying drawing, the present invention will be further described:

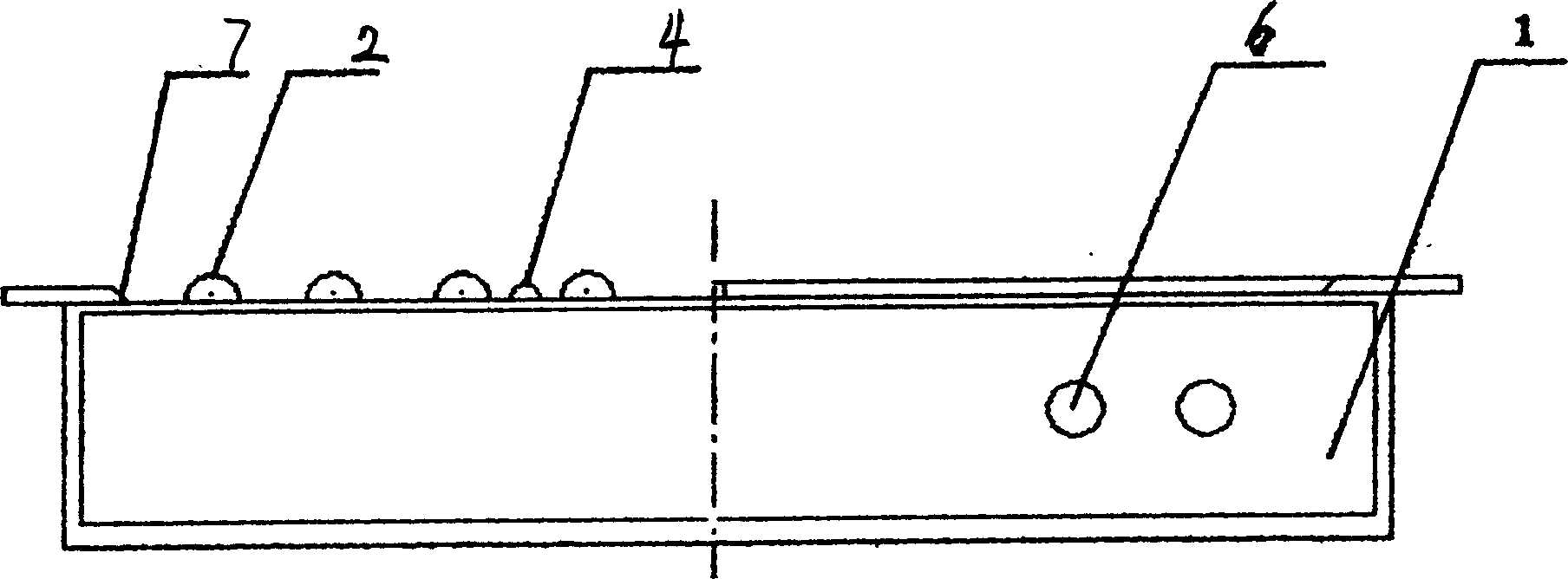

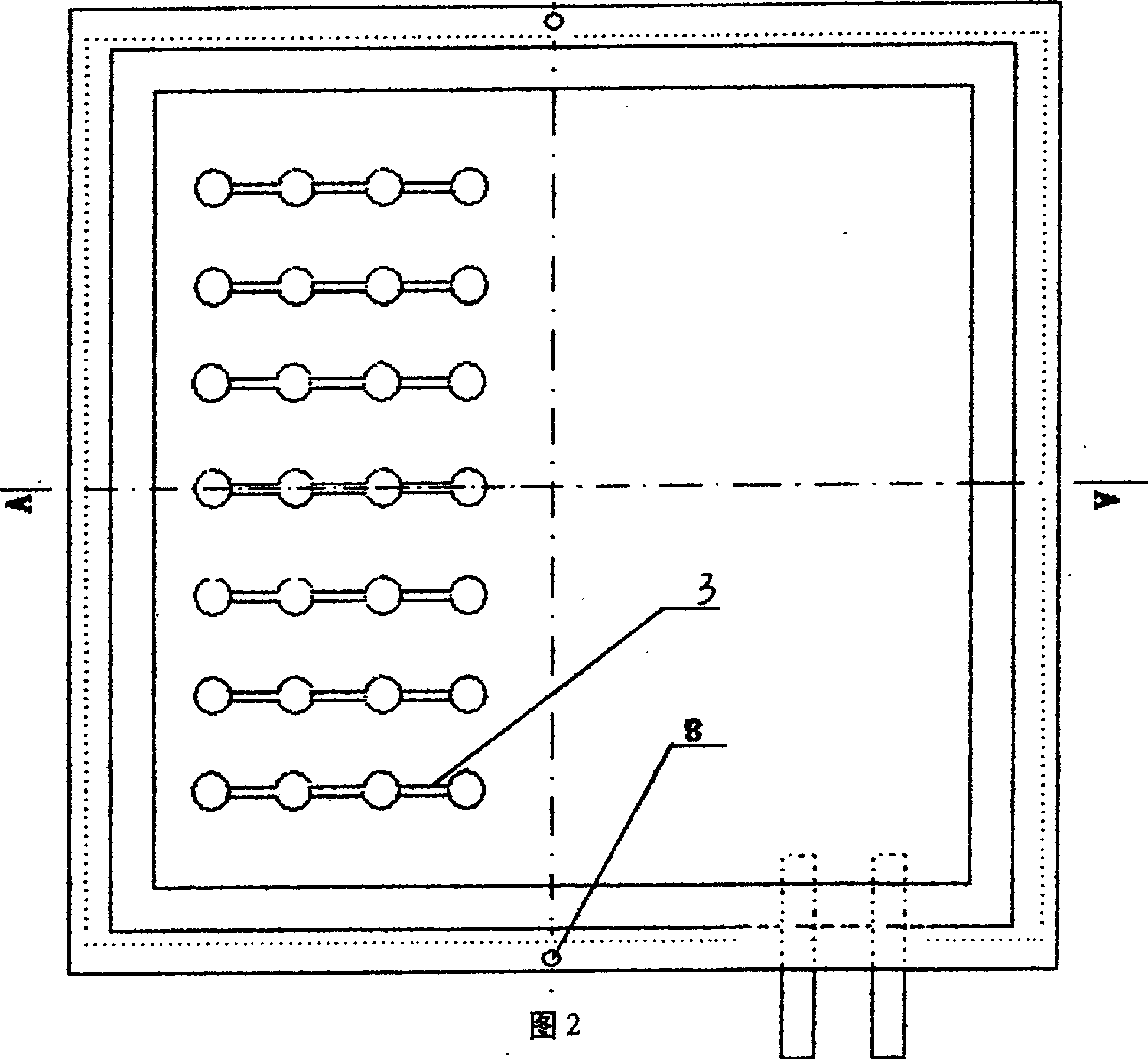

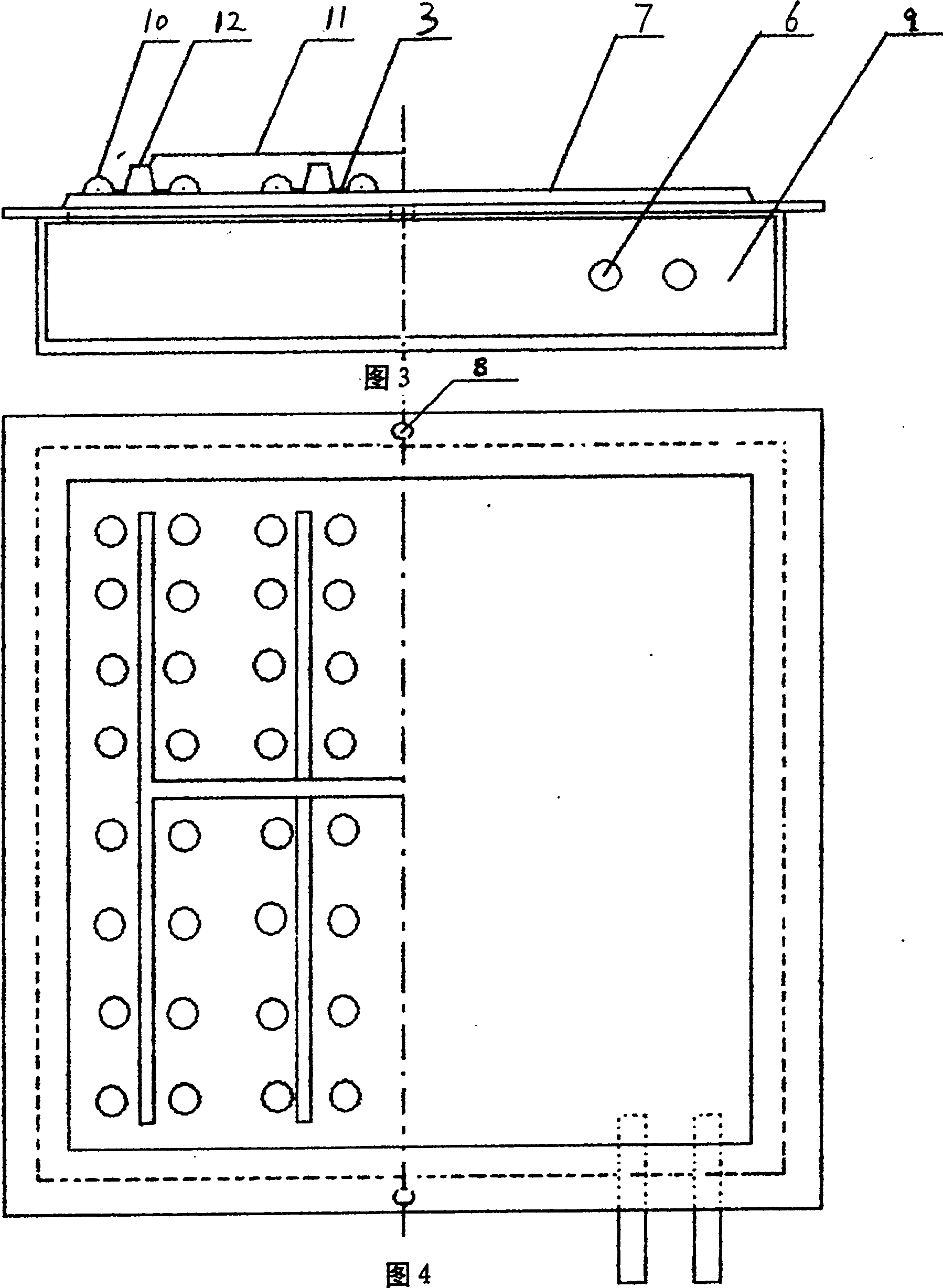

[0027] The vacuum sealing method for producing grinding balls is carried out in the following steps:

[0028] The first step is to extract air from the lower mold box of the ball mold, and then cover the mold surface of the lower mold box of the ball mold with a film, then place the lower box of the ball tool on the lower mold box of the ball mold, Fill sand in the lower box of the tooling and vibrate it, cover the surface of the lower box of the vibration ball tooling with a backing film and pump air, and finally pull out the mold to get the lower model of the ball;

[0029] In the same way, the upper mold box of the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com