Electrostatic chuck with heater

An electrostatic chuck and heater technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of longer substrate processing time, lower substrate processing capacity, and deterioration of device yield, so as to improve heating efficiency , good heat uniformity, and high long-term reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be described below.

[0015] The electrostatic chuck will be described.

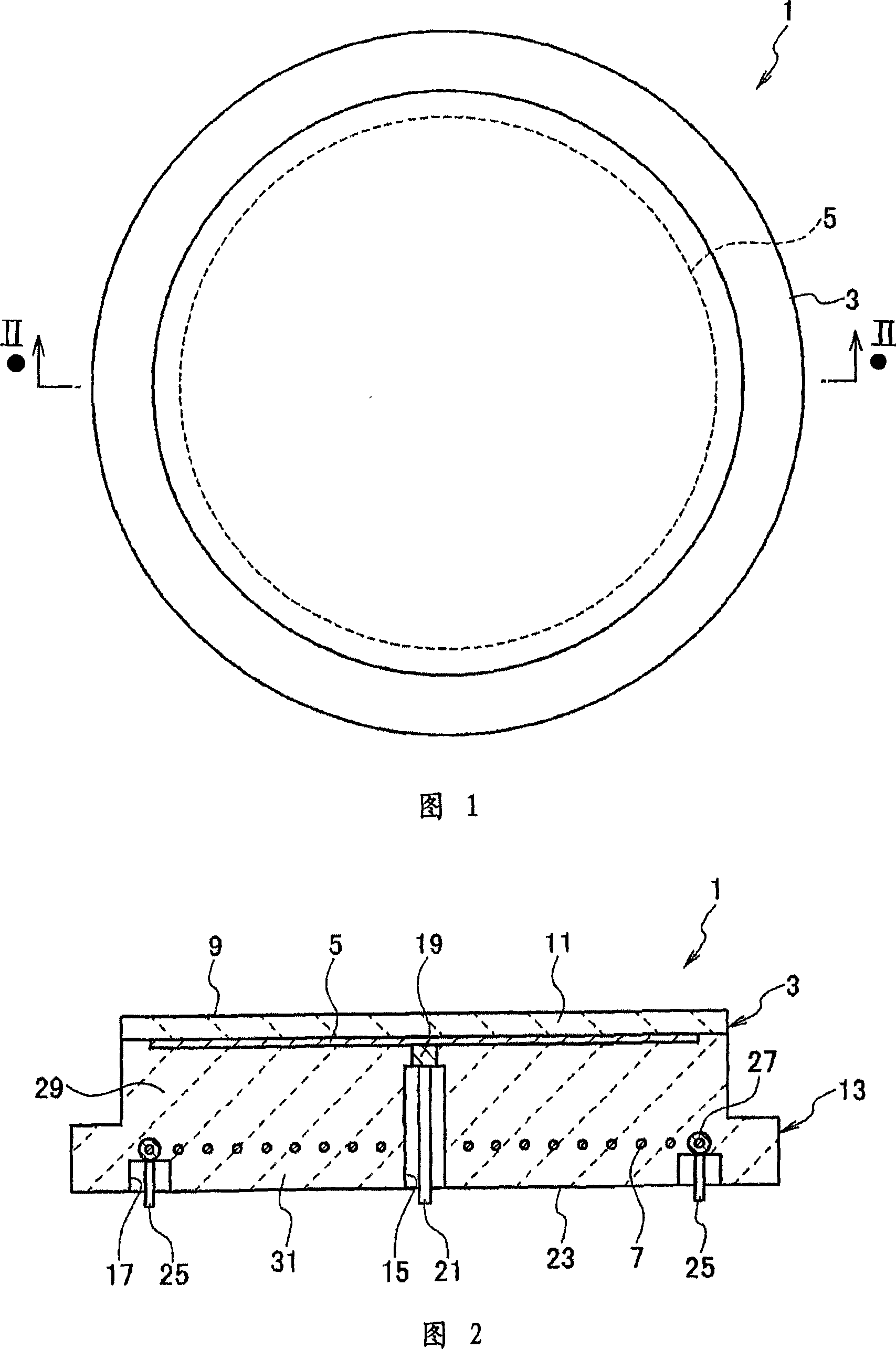

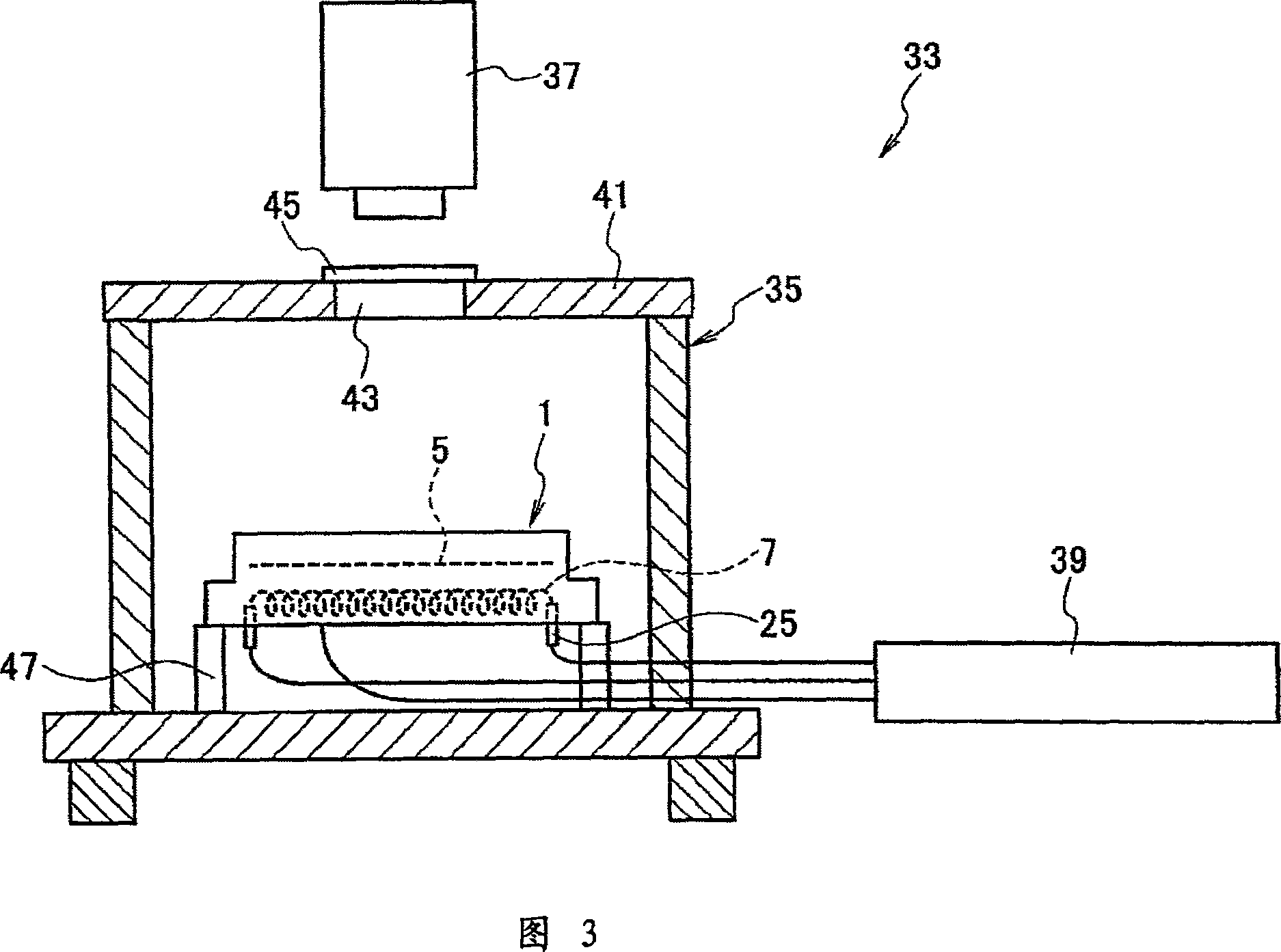

[0016] 1 is a plan view showing an electrostatic chuck with a heater according to an embodiment of the present invention, and FIG. 2 is a cross-sectional view taken along line II-II of FIG. 1 .

[0017] As shown in FIGS. 1 and 2 , an electrostatic chuck with a heater 1 according to an embodiment of the present invention includes: a base body 3 made of a sintered body containing alumina; an electrode 5 embedded in the upper side of the base body 3 ; and The resistance heating element 7 is embedded in the lower side of the base body 3 .

[0018] Describe the base.

[0019] As shown in FIGS. 1 and 2 , the base 3 is formed in a disk shape, and the upper surface (surface) of the base 3 is formed as a substrate mounting surface 9 on which a substrate such as a wafer is mounted. Furthermore, a portion from the electrode 5 to the upper side in the base body 3 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com