Waste heat recovery type thermoelectricity cold jointly-supplying technology

A technology of combined heat, power and cooling, waste heat recovery, applied in heating methods, energy-saving heating/cooling, hot water central heating systems, etc. The effect of thermal area, alleviation of power shortage, huge economic and development value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

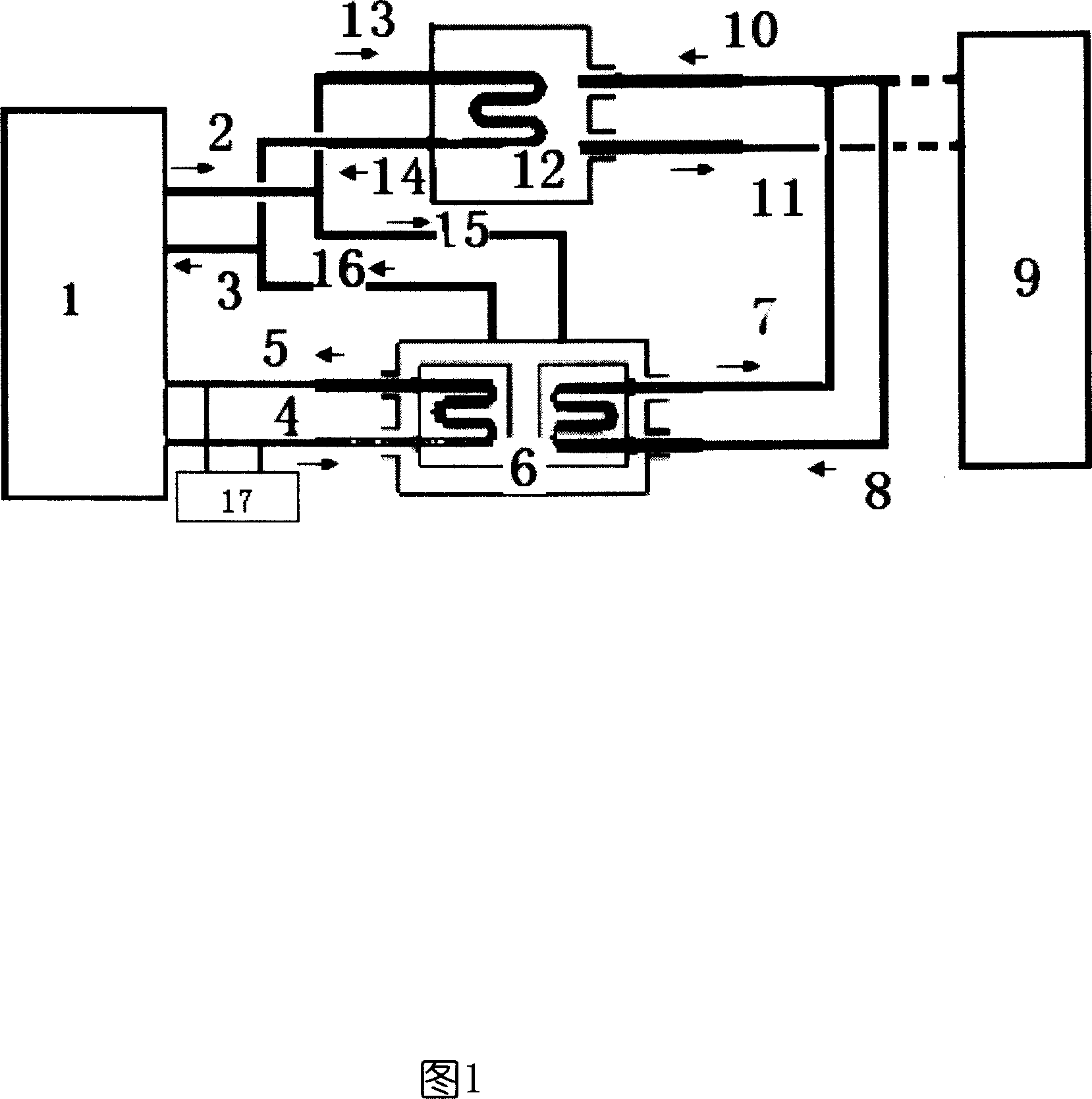

[0014] In Fig. 1, when supplying heat, the steam extracted from the steam turbine of the thermal power plant (1) enters the pipe (2), and is divided into two parts by flow regulation, and a part of the steam enters the absorption heat pump (6) through the pipe (15), after driving the heat pump The steam turns into high-temperature hot water and returns to the boiler through the pipeline (16) and the pipeline (3), and the heat pump condenser end raises the temperature of the heating return water in the pipeline (8) to 80°C and passes through the pipeline (7) and the pipeline (10). The heat supply and return water are mixed into the steam heat exchanger; another part of the steam enters the steam heat exchanger (12) through the pipe (13), and after heat exchange with the heat supply return water and the hot water prepared by the heat pump, it becomes high-temperature hot water. Return to the boiler through pipeline (14), pipeline (2). The high-temperature hot water exchanged by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com