Gas lifting reverse circulation porus cleaning construction method for slurry bulkhead cast-in-situ bored pile

A technology of gas-lift reverse circulation and bored piles, which is applied in the direction of sheet pile walls, cleaning equipment, earth square drilling and mining, etc., can solve the problems that the sediment cannot be cleaned and the bearing capacity of the pile is reduced, so as to save land and water resources, Emission reduction and easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

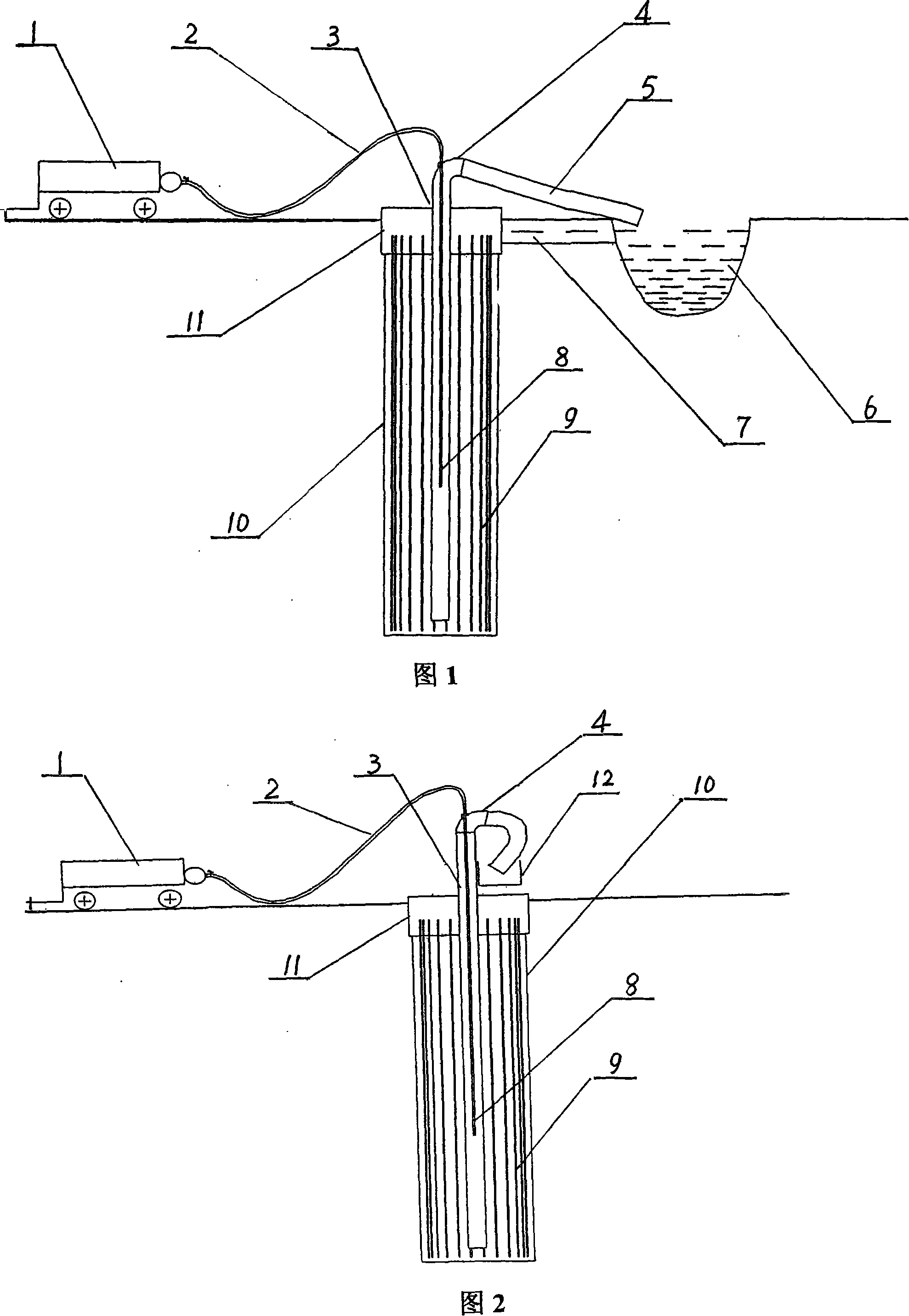

Image

Examples

Embodiment

[0031] Be 1000mm with diameter, pile length 40m pile is example, utilize its construction sequence of the present invention to be: 1, measure and place pile position; 2, drilling rig is in place; 3, bury hole casing; 6. Set up a steel conduit (including the top section of the conduit); 7. Place an air compressor; 8. Set up a high-pressure hose; 9. Connect the high-pressure hose to the air compressor; Circular cleaning of holes; 11. Pouring concrete into piles. The specific implementation process is detailed as follows:

[0032] After measuring and determining the position of the pile, the drilling rig began to be in place, and the casing in the hole was buried, and the construction was ready to start. Use the Φ1000mm drill bit to drill the hole. When the groundwater level is high, or the formation is prone to collapse, a high-quality stabilizing solution should be prepared in advance, specifically made of bentonite, caustic soda and cellulose, with a specific gravity of not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com