Traction machine for resin basis composite material sectional material

A technology of composite materials and tractors, applied in the field of machinery, to achieve the effects of less energy consumption, good consistency of action, and balanced traction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

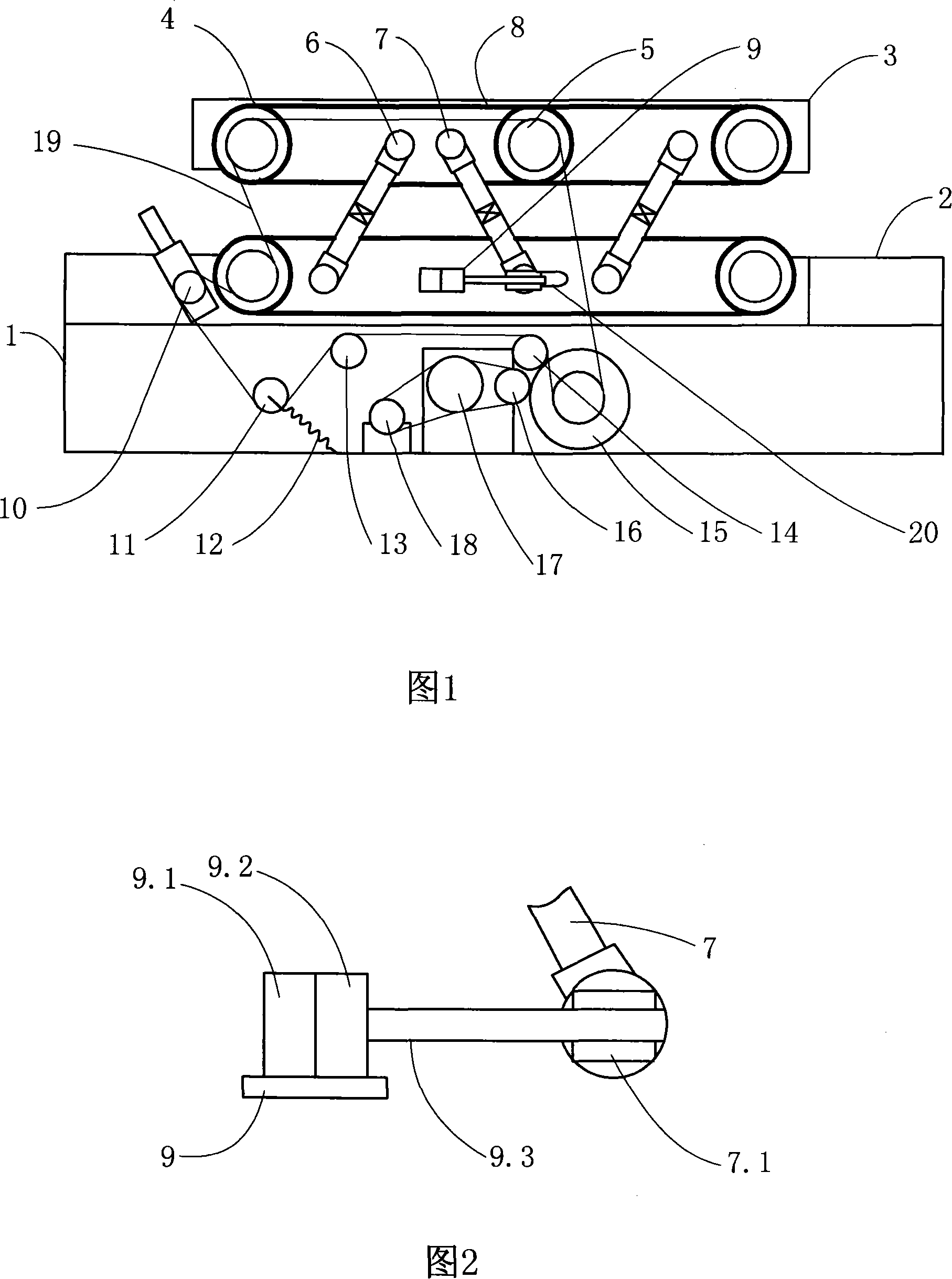

[0011] As shown in Figure 1, the lower machine base 2 is installed on the frame 1 and the upper machine base 3 is installed through the motorized gap adjustment rod 7 and the limit rod 6, and the two ends of the lower and upper machine bases are respectively equipped with clamping transmission The pulley 4 is connected with a clamping transmission belt 8 around the closed package on the clamping transmission pulley, and there is a gap between the upper and lower clamping transmission pulleys, and the upper base power transmission wheel 5 is installed on the upper base , the lower end of the motorized gap adjustment rod is installed in the sliding hole 20, and is connected with the motorized gap adjustment rod driver 9 through a screw rod, and a transmission chain tension regulator 10 is installed on one side of the lower machine base, and a transmission chain tension regulator 10 is installed on the frame. Adjuster 11, on which tightening spring 12 is installed, and left transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com