Method of eliminating sodium chloride in iron-dextran complex compound water solution and device thereof

A technology of iron dextran and dextran, which is applied in the field of removing sodium chloride in an aqueous solution of iron dextran complexes and devices, can solve the problems of colloidal particle electrodialysis operation and high viscosity of materials, and achieve easy control, lower operating costs and The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

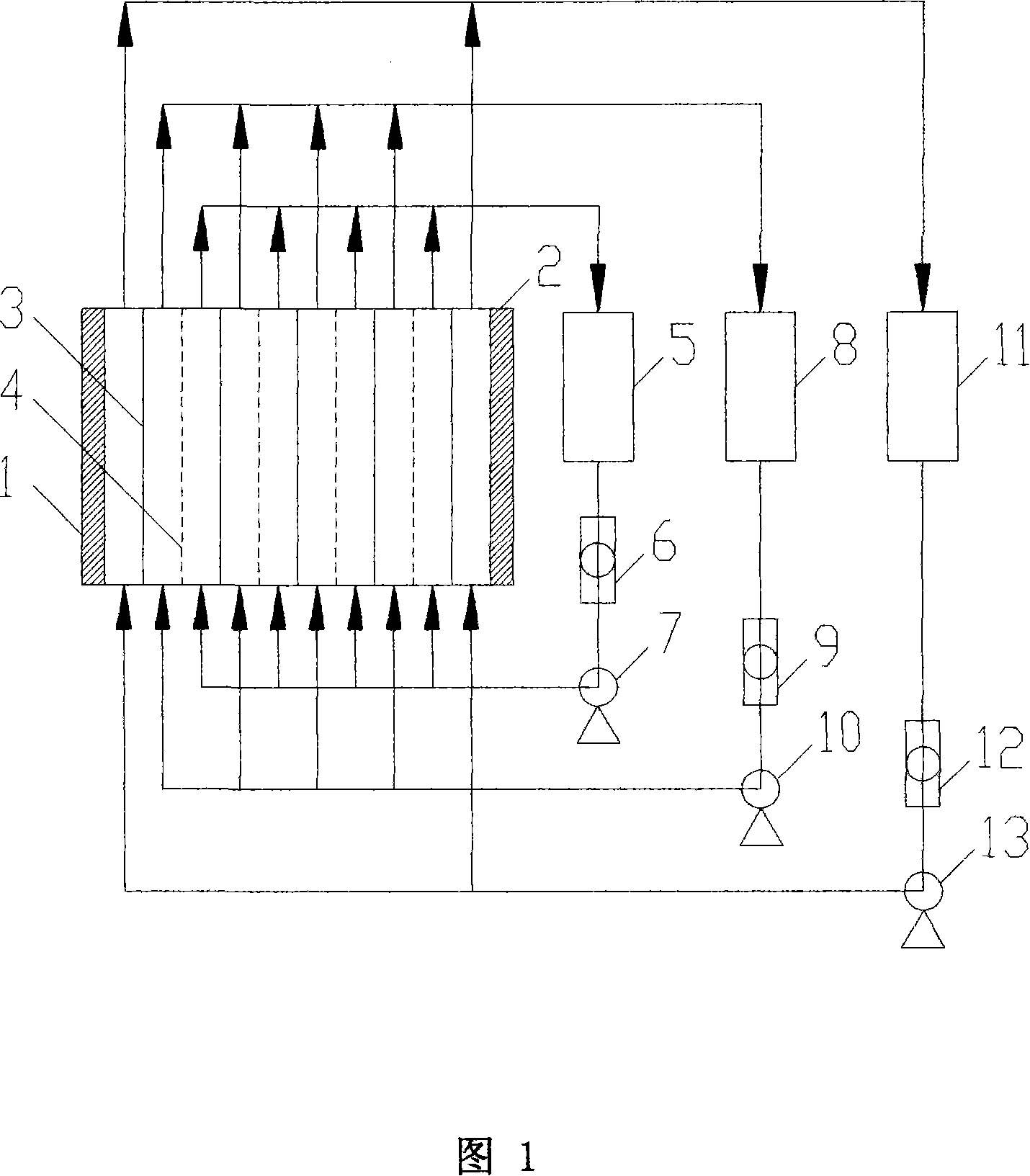

Image

Examples

Embodiment 1

[0026]In the raw material circulation storage tank, the brine circulation storage tank, and the electrode liquid circulation storage tank, respectively add 40% of an aqueous solution of iron dextran complex with a salt content of 15% (w / w, the same below) and an iron content of 50 mg / mL. liter, 0.5% sodium chloride solution, 0.5% sodium sulfate solution, wherein the amount of sodium chloride solution and sodium sulfate solution is advisable to meet the cycle of electrodialysis process. Start the material liquid circulation pump, and after the material circulation is stable, apply direct current until the current density is 50mA / cm 2 , keep the voltage constant, and carry out constant voltage electrodialysis. During the electrodialysis process, distilled water was continuously added to maintain the iron dextran solution volume at 40 liters. During the electrodialysis process, the solution temperature was controlled at 15°C. Along with the carrying out of electrodialysis proces...

Embodiment 2

[0028] Add 80kg of iron dextran solution with iron content ≥ 50mg / mL and 15% salt content, 0.5% sodium chloride solution, and 0.5% sulfuric acid in the raw material circulation storage tank, brine circulation storage tank, and electrode solution circulation storage tank. Sodium solution, wherein the amount of sodium chloride solution and sodium sulfate solution is advisable to meet the electrodialysis process cycle. Start the material liquid circulation pump, and after the material circulation is stable, apply direct current until the current density is 55mA / cm 2 , keep the voltage constant, carry out constant voltage electrodialysis and control the solution temperature to 55°C. Along with the carrying out of electrodialysis process, electric current constantly drops, and when energizing amount reaches 5497 ampere hours, stops electrodialysis, discharges, and obtains sodium chloride content and is less than 1.0%, and iron content is greater than 45kg of dextran iron solution o...

Embodiment 3

[0030] Add 130kg of iron dextran solution with iron content ≥ 50mg / mL and 15% salt content, 0.5% sodium chloride solution, and 0.5% sulfuric acid in the raw material circulation storage tank, brine circulation storage tank, and electrode solution circulation storage tank. Sodium solution, wherein the amount of sodium chloride solution and sodium sulfate solution is advisable to meet the electrodialysis process cycle. Start the material liquid circulation pump, and after the material circulation is stable, apply direct current until the current density is 55mA / cm 2 , keep the voltage constant, carry out constant voltage electrodialysis and control the solution temperature not higher than 90°C. Along with the carrying out of electrodialysis process, electric current constantly drops, and when energizing amount reaches 8932 ampere hours, stops electrodialysis, discharges, and obtains sodium chloride content and is less than 2.0%, and iron content is greater than 43kg of iron dext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com