LED drive system and backlight module with same

A technology for light-emitting diodes and driving systems, which is applied to electroluminescent light sources, semiconductor devices of light-emitting elements, optics, etc., can solve the problems of complicated manufacturing process of light-emitting diode light rods, inability to detect the temperature of light-emitting diodes, etc., and achieves a long working life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

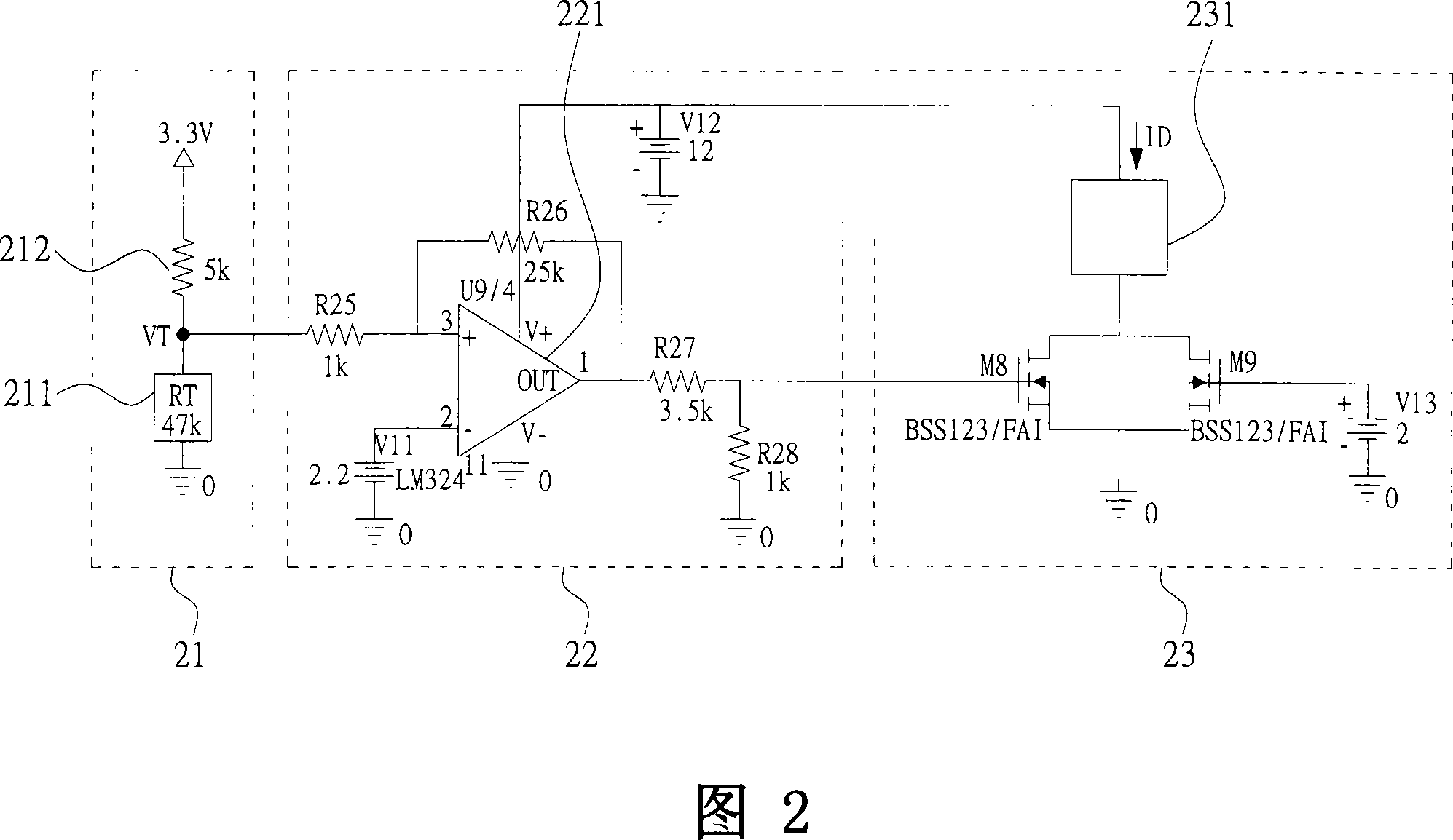

[0047] 2 is a system architecture diagram of an LED driving system according to an embodiment of the present invention, wherein the LED driving system according to an embodiment of the present invention includes: a temperature detection module 21, a hysteresis voltage module electrically connected to the temperature detection module 21 22 and a current limiting module 23 electrically connected to the hysteresis voltage module 22 and a light emitting diode 231 . In addition, an LED driving system according to an embodiment of the present invention is disposed on a circuit board (not shown in the figure), and the above-mentioned LEDs 231 are electrically connected to the circuit board (not shown in the figure).

[0048] On the other hand, the temperature detection module 21 of the LED driving system according to an embodiment of the present invention is connected to the LED 231 and includes a thermoelectric conversion unit 211 , and the hysteresis voltage module 22 includes a hys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com